Method for processing wastewater from production of epoxy chloropropane by using glycerol as material

A technology of epichlorohydrin and treatment method, which is applied in natural water treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of not realizing the maximum resource utilization of pollutants and affecting the application of technology, etc. To achieve the effect of easy operation and control, obvious economic benefits, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

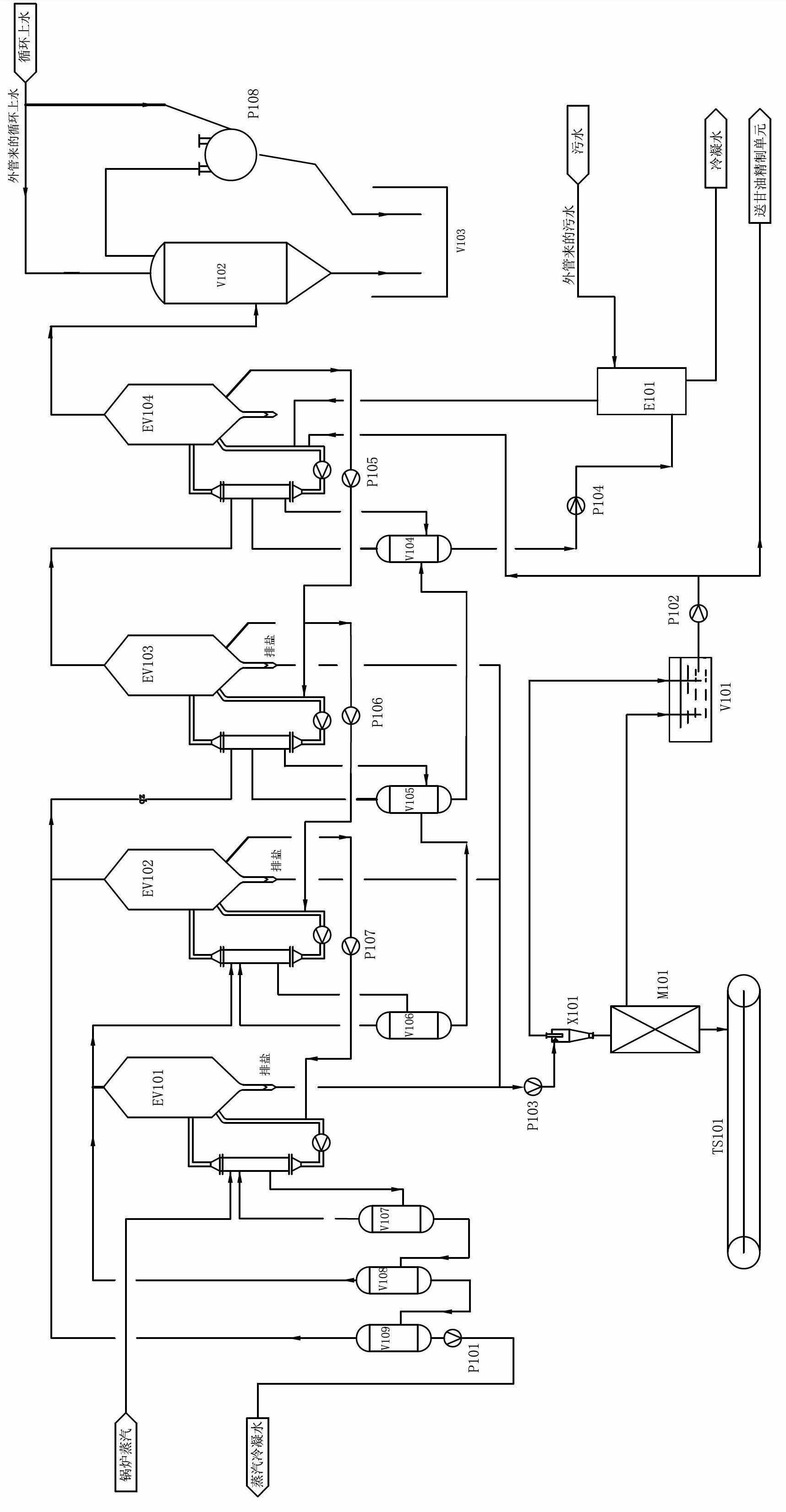

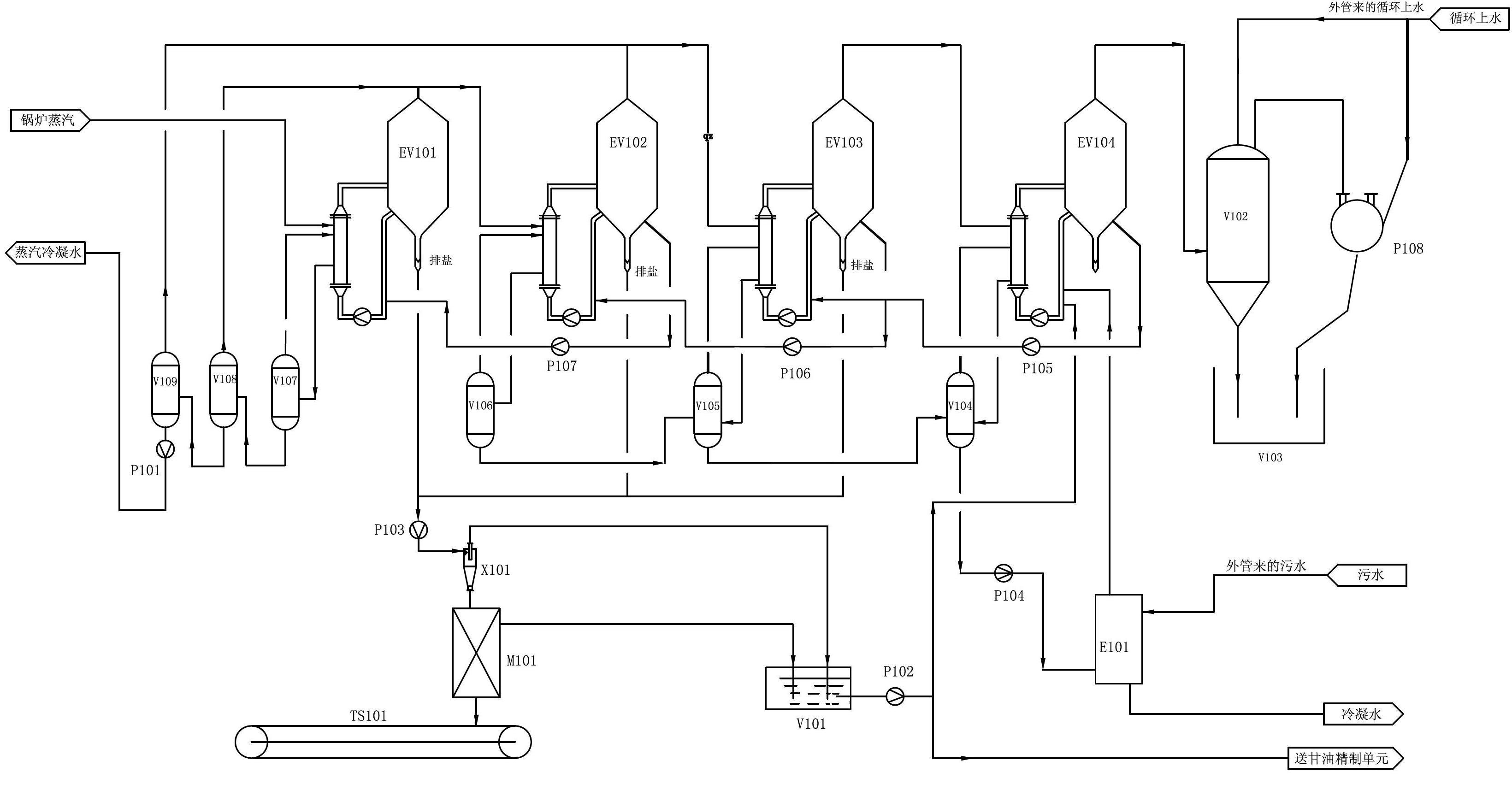

[0023] The amount of high-salinity organic wastewater produced by the ECH saponification and cyclization process in a factory is 15t / h. The wastewater composition is: NaCL 20% (weight ratio), NaOH 0.7% (weight ratio), glycerin 4500ppm, chlorine-containing organic matter 50ppm, COD 5500mg / L.

[0024] 15t / h high-salinity organic wastewater is sent to the preheater (E101) after being clarified and filtered to exchange heat with the condensed water from the IV-effect balance barrel (V104). After being heated to 40°C, it enters the IV-effect evaporation tank (EV104 ), under the condition of 0.04Mpa, it is heated to 75°C by circulation, and 3.526t / h of waste water vapor is generated, which is sucked into the mixing condenser (V102) by the vacuum pump (P108), and recovered to the water-sealed pool (V103) after condensation;

[0025] The concentrated liquid in the IV effect evaporator (EV104) is sent to the III effect evaporator (EV103) by the IV effect transfer pump (P105), and is he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com