Preparation method for adsorption material for polluted water heavy metals and treatment method for polluted water heavy metals

A technology of adsorption material and treatment method, applied in the field of phytochemistry and adsorption science, can solve the problems of low content of active components and unsatisfactory adsorption capacity, and achieve the effect of good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

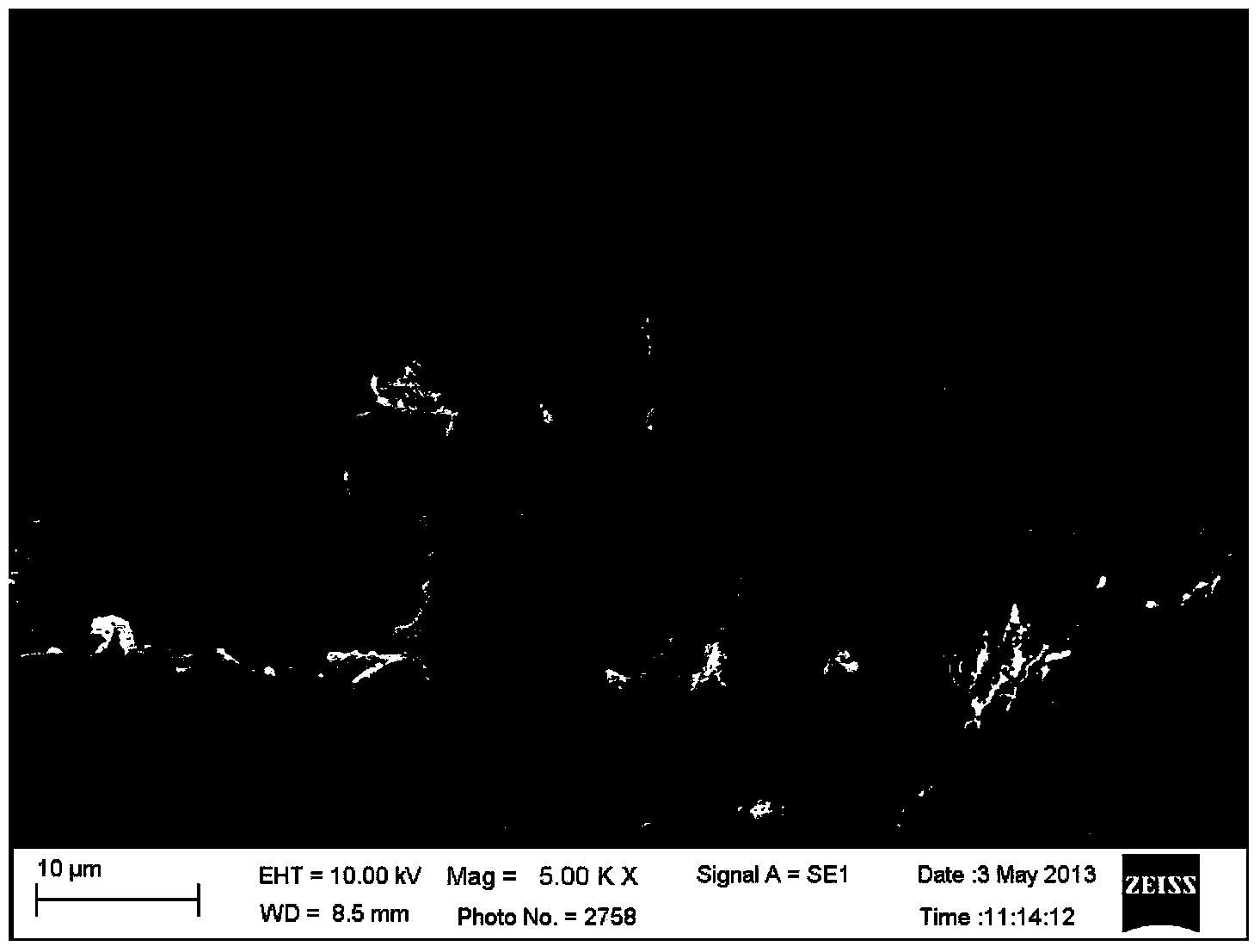

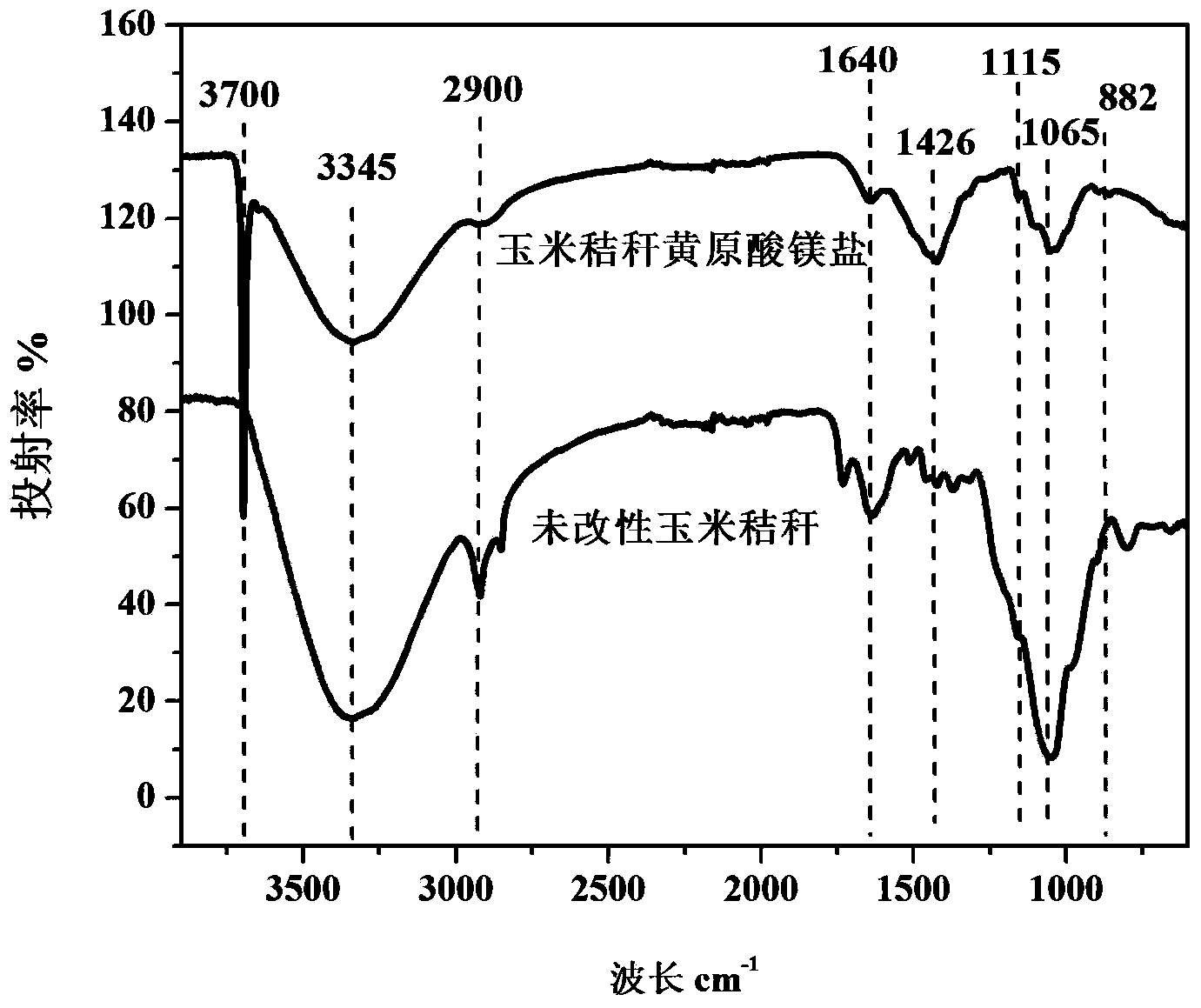

Image

Examples

Embodiment 1

[0039] 1) Remove the residual leaves and knots on the straw, wash the residual soil residue and dust with tap water, then rinse with deionized water three times, dry in the air (or dry at 50°C), and then crush through a 20-mesh sieve , to obtain corn stalk powder and set aside.

[0040] 2) Immerse the corn stalk powder in an aqueous sodium hydroxide solution with a concentration of 10wt% (solid-to-liquid ratio: 10g / ml), and soak and react for 120 minutes at room temperature;

[0041] 3) Then add an aqueous solution of epichlorohydrin with a concentration of 90wt% (solid-to-liquid ratio is 10g / ml), under normal temperature conditions, soak and react for 18 hours, then suction filter to obtain a solid sample a;

[0042] 4) Immerse the solid sample a in an aqueous sodium hydroxide solution with a concentration of 10wt% (solid-liquid ratio of 10g / ml), and then add a carbon disulfide aqueous solution with a concentration of 90wt% (solid sample a and its solid-liquid ratio are 10g / m...

Embodiment 2

[0050] 1) Remove the residual leaves and knots on the straw, wash the residual soil residue and dust with tap water, and then wash it with deionized water three times, dry it in the air (or dry it at 50°C), and then crush it through an 80-mesh sieve , to obtain corn stalk powder and set aside.

[0051] 2) Immerse the corn stalk powder in a sodium hydroxide solution with a concentration of 1wt% (solid-to-liquid ratio: 100g / ml), and soak and react for 60 minutes at room temperature;

[0052] 3) Then add an aqueous solution of epichlorohydrin with a concentration of 85wt% (solid-to-liquid ratio is 100g / ml), soak and react for 12 hours under normal temperature conditions, and then suction filter to obtain a solid sample a;

[0053] 4) Immerse the solid sample a in a sodium hydroxide solution with a concentration of 1wt% (solid-liquid ratio is 100g / ml), and then add a carbon disulfide aqueous solution with a concentration of 85% (solid sample a and its solid-liquid ratio are 100g / m...

Embodiment 3

[0057] 1) Remove the residual leaves and knots on the straw, wash the residual soil residue and dust with tap water, and then wash it three times with deionized water, dry it in the air (or dry it at 50°C), and then crush it through a 60-mesh sieve , to obtain corn stalk powder and set aside.

[0058] 2) Immerse the corn stalk powder in a potassium hydroxide solution with a concentration of 8wt% (solid-to-liquid ratio: 1g / ml), and soak and react for 70 minutes at room temperature;

[0059] 3) Then add an aqueous solution of epichlorohydrin with a concentration of 95wt% (solid-to-liquid ratio is 1g / ml), soak and react for 24 hours under normal temperature conditions, and then suction filter to obtain a solid sample a;

[0060] 4) Immerse the solid sample a in a potassium hydroxide solution with a concentration of 5wt% (solid-liquid ratio is 1g / ml), and then add a carbon disulfide aqueous solution with a concentration of 95% (solid sample a and its solid-liquid ratio are 1g / ml),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com