Method for processing industrial wastewater of polytetrafluoroethylene dispersion resins

A technology of polytetrafluoroethylene and dispersed resin, which is applied in natural water treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of incomplete collection, easy-to-carry dispersed resin, and suspended solids content High-level problems, to achieve the effect of convenient industrial operation, significant economic and social benefits, and good recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

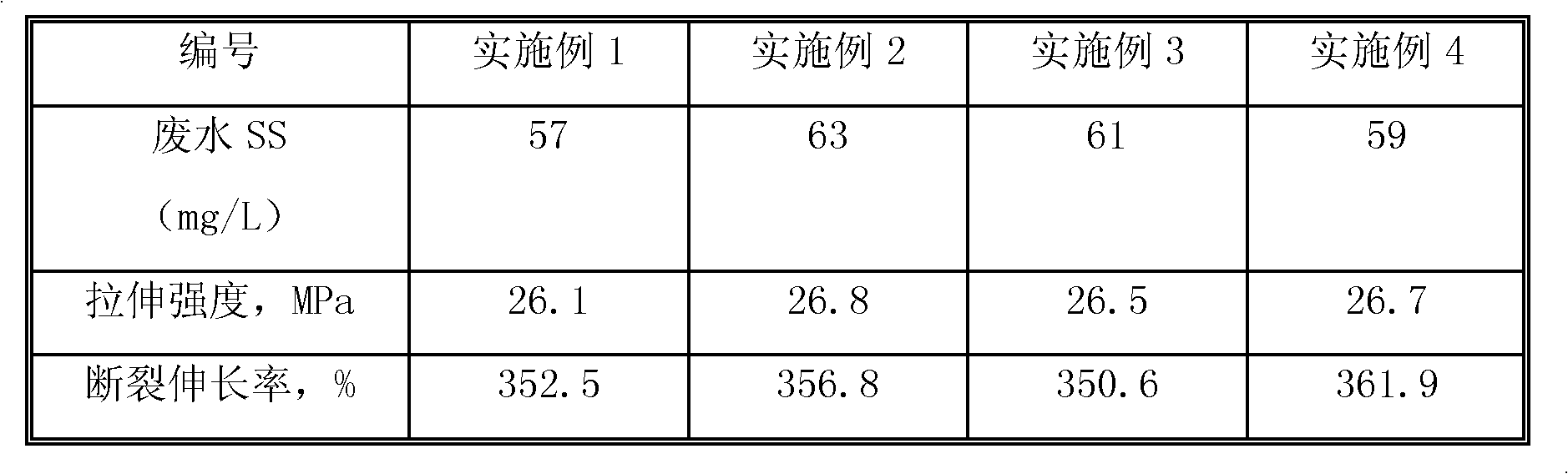

Embodiment 1

[0018] The polytetrafluoroethylene dispersed wastewater with a solid content of 0.5% enters the dissolved air flotation machine at a constant speed of 5t / h, and the air is sent to the pressure dissolved air tank through the compressor, the pressure is controlled at 0.5MPa, and then enters the air flotation tank suddenly Reduce the dissolved air pressure to normal pressure, and the air dissolved in the waste water is separated out to form a large number of dense microbubbles. At the same time, a 20% mass concentration of polyaluminum chloride solution and Disperse and mix the waste water, make the waste water demulsify and separate out the resin, and form flocculent solid under the action of polyaluminum chloride, the microbubbles are adsorbed on the surface of the flocculent solid during the slow rising process, bringing the flocculent solid to the surface of the waste water, and the resin is released The waste water is discharged from the bottom of the air flotation machine. ...

Embodiment 2

[0020] The polytetrafluoroethylene dispersed wastewater with a solid content of 0.2% enters the dissolved air flotation machine at a constant speed of 5t / h, the pressure of the dissolved air system is 0.8MPa, and the polyferric sulfate with a content of 10% is added at a rate of 25kg / h by a pump The air flotation machine is mixed with the dispersed wastewater. The precipitated dispersed resin enters the storage tank under the scraper collection, and is pumped into the plate and frame filter for filtration. The filter cake is taken out and dried to obtain a polytetrafluoroethylene dispersion resin. Others are with embodiment 1.

Embodiment 3

[0022] The polytetrafluoroethylene dispersed wastewater with a solid content of 0.25% enters the dissolved air flotation machine at a constant speed of 5t / h, the pressure of the dissolved air system is 0.6MPa, and the aluminum potassium sulfate with a content of 12% is added at a speed of 25kg / h by a pump The air flotation machine is mixed with the dispersed wastewater. The precipitated dispersed resin enters the storage tank under the scraper collection, and is pumped into the plate and frame filter for filtration. The filter cake is taken out and dried to obtain a polytetrafluoroethylene dispersion resin. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com