Method for preparing composite hydrogel through modifying bamboo shoot leftovers and application of composite hydrogel

A technology of composite hydrogel and leftovers, applied in chemical instruments and methods, other chemical processes, fiber raw material processing, etc., can solve problems such as production, life and health adverse effects, waste of biomass resources, waste of resources and the environment, etc. Achieve the effects of easy industrial operation, strong adsorption capacity and stable adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

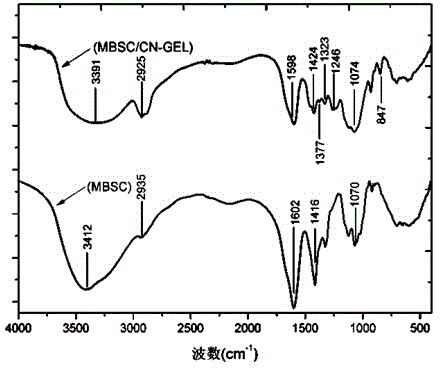

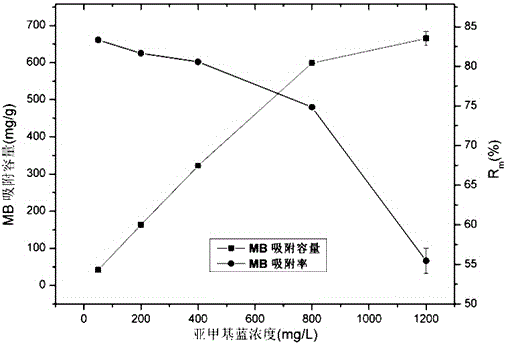

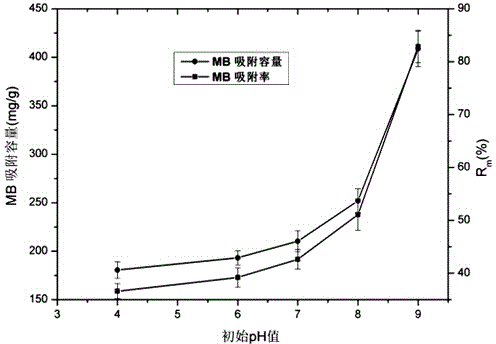

Method used

Image

Examples

Embodiment 1

[0045] (1) Bamboo shoot leftovers are washed, dried at 70° C. for 12 hours, cut into small pieces, pulverized by a pulverizer and passed through an 80-mesh sieve to obtain bamboo shoot residue powder with a particle size of 0.1-0.6 mm.

[0046] (2) Add distilled water according to the ratio of material-water ratio (mass ratio) 1:20 of bamboo shoot leftovers, carry out deenzyming treatment at 70°C for 2 hours to passivate active enzymes of bamboo shoots, and then use glacial acetic acid with a mass fraction of 10% Adjust the pH of the solution at 3.8. After the adjustment, add sodium chlorite for bleaching treatment for 2 hours. The mass ratio of the amount of sodium chlorite added to the bamboo shoot leftovers powder is 1:1, and bleaching treatment is carried out at 80°C to remove Lignin in bamboo shoot leftovers;

[0047] (3) After bleaching, filter the insoluble flocculent in the solution, wash it with distilled water until the filtrate is colorless, finally use 90% ethanol ...

Embodiment 2

[0059] (1) Bamboo shoot leftovers are washed, dried at 80° C. for 16 hours, cut into small pieces, pulverized by a pulverizer through an 80-mesh sieve to obtain bamboo shoot residue powder, and the particle size of the powder is 0.1-0.6 mm.

[0060] (2) Bamboo shoot leftovers powder is added to distilled water according to the ratio of material-water ratio (mass ratio) 1:25, and the active enzymes of bamboo shoots are inactivated for 2.5 hours at 65 ° C, and then the mass fraction is 10% ice Acetic acid is used to adjust the pH of the solution to 4.0. After the adjustment, sodium chlorite is added for bleaching treatment for 2 hours. The mass ratio of the amount of sodium chlorite added to the bamboo shoot leftover powder is 0.9:1, and the bleaching treatment is carried out at 80°C. Removal of lignin in bamboo shoot leftovers.

[0061] (3) After bleaching, filter the insoluble flocculent in the solution, wash it with distilled water until the filtrate is colorless, finally use...

Embodiment 3

[0072] (1) Bamboo shoot leftovers are washed, dried at 75° C. for 16 hours, cut into small pieces, pulverized by a grinder and passed through an 80-mesh sieve to obtain bamboo shoot residue powder with a particle size of 0.1-0.6 mm.

[0073] (2) Bamboo shoot leftovers powder is added distilled water according to the ratio of material water ratio 1:20, under the condition of 70 DEG C, carry out deenzyming treatment 2h passivation bamboo shoot active enzymes, adjust solution pH at 3.8 with 10% glacial acetic acid afterwards, adjust After completion, add sodium chlorite for bleaching treatment for 3 hours, the mass ratio of the amount of sodium chlorite added to the bamboo shoot leftovers powder is 1:1, and bleaching treatment is carried out at 80°C to remove the lignin in the bamboo shoot leftovers .

[0074] (3) After bleaching, filter the insoluble flocculent in the solution, wash it with distilled water until the filtrate is colorless, finally use 95% ethanol to wash with alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com