Forming SCR catalyst with both water resistance and sulphur resistance and preparation method thereof

A technology of catalyst and denitrification catalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unfavorable industrial application and cumbersome preparation process, and achieve industrial operation, not easy to break, and good deliquescence resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

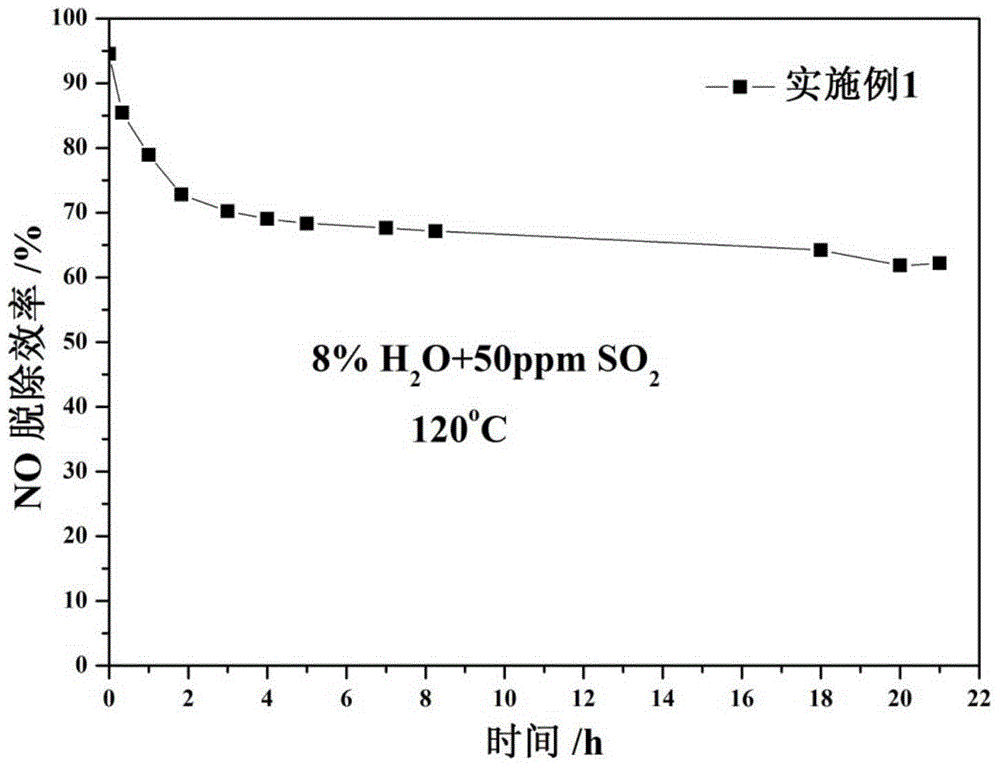

Embodiment 1

[0035] 1. Preparation of low-temperature SCR denitrification catalyst

[0036] (1) Dry mixing: take 400g carrier anatase TiO 2 , 8gWO 3 , 358g manganese oxalate, 260.4g, cerium nitrate, 42.9g zirconium nitrate, 87.3g cobalt nitrate (weighed first, and then placed in an oven for 48h at 120°C) and other active material precursor powders and 10g stearic acid, 20g Activated carbon, 10g pseudo-boehmite, etc. were put into a kneader and dry-mixed for 45 minutes to obtain a uniformly mixed powder;

[0037] (2) Wet mixing granulation: add 50g of glass fiber and 5g of pulp cotton to the powder, stir for 15min to combine the material into a filament, then add glycerin evenly for several times and spray misty deionized water, glycerin and deionized water The total amount of ionized water is 20g and 30g respectively, so that the materials are gradually combined to form granules, and the time is 30min;

[0038] (3) Wet mixing: continue to add liquid glycerin and mist deionized water to ...

Embodiment 2

[0050] 1. Preparation of low-temperature SCR denitrification catalyst

[0051] Change the 87.3g cobalt nitrate quality into 29.1g in the catalyst formula of embodiment 1, the add-on of deionized water becomes 20g in the wet mixing granulation process, the deionized water add-on becomes 60g in the wet mixing granulation process, other formula materials and The preparation method is consistent with Example 1.

[0052] 2. Mechanical performance test

[0053] The test conditions were the same as in Example 1, and the measured longitudinal mechanical strength of the catalyst was 1.7 MPa.

[0054] 3. Catalyst activity test

[0055] The test conditions were the same as in Example 1. After 8 hours of testing, the conversion rate of NO decreased from 99% to 44%, and tended to balance.

Embodiment 3

[0057] 1. Preparation of low-temperature SCR denitrification catalyst

[0058] Change the 87.3g cobalt nitrate quality into 174.6g in the catalyst formula of embodiment 1, the add-on of deionized water becomes 10g in the wet mixing granulation process, the deionized water add-on becomes 20g in the wet mixing granulation process, other formula materials and The preparation method is consistent with Example 1.

[0059] 2. Mechanical performance test

[0060] The test conditions were the same as in Example 1, and the measured longitudinal mechanical strength of the catalyst was 1.4 MPa.

[0061] 3. Catalyst activity test

[0062] The test conditions were the same as in Example 1. After 19 hours of continuous testing, the conversion rate of NO decreased from 93% to 49.6%, and tended to be stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com