Novel abrasion-resistant, anti-corrosion and anti-static coating and preparation method thereof

An anti-static coating and anti-corrosion technology, applied in the direction of anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of difficulty in evacuating static electricity and easy wear and tear, and achieve the goal of evacuating static electricity on the surface of the coating, preventing wear and saving working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

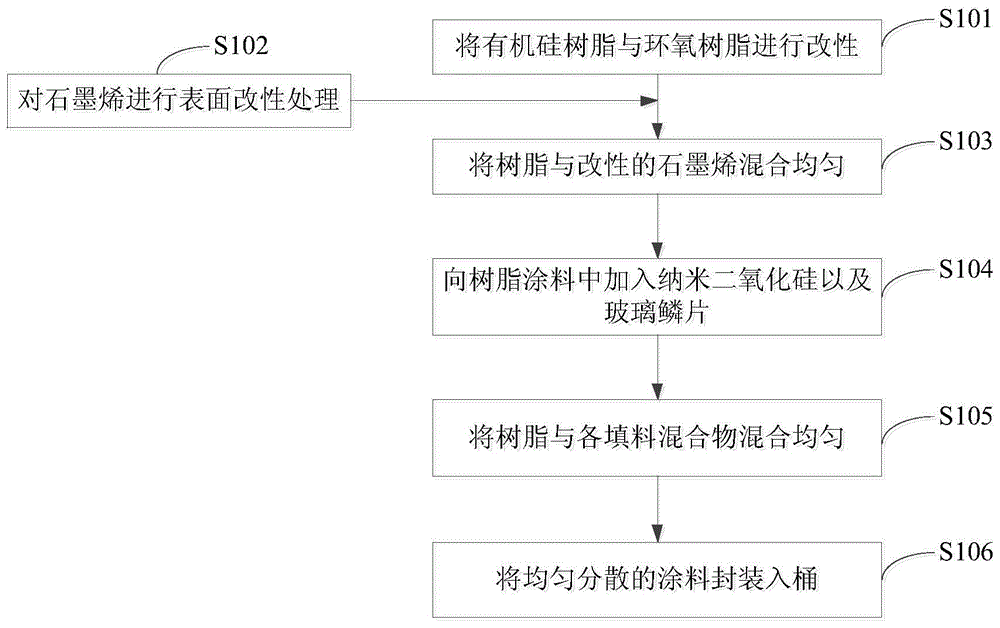

[0031] Please refer to figure 1 , the present embodiment adopts graphene, nano-silicon dioxide and glass flakes to prepare the flow chart of the epoxy resin coating modified by silicone resin with wear-resistant, anti-corrosion, anti-static properties, comprising the following steps:

[0032] S101: Modification of silicone resin and epoxy resin

[0033] First mix the silicone resin with the epoxy resin and stir well.

[0034] Then add a small amount of silane coupling agent to the mixed resin to improve the compatibility of the two resins.

[0035] S102: Surface modification of graphene

[0036] Add graphene into concentrated sulfuric acid at a ratio of 5‰, and cool down to about 0°C. Stir evenly, then slowly add a small amount of potassium permanganate, heat up to room temperature and stir for more than 3 hours, until the solution becomes a paste, cool to about 0°C, add deionized water, stir at a high speed, and then add hydrogen peroxide until no bubbles are generated. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com