A display panel and its manufacturing method

A technology for display panels and substrates, applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problems that the sealing layer does not have light-shielding ability and the risk of large light leakage, and achieve the effect of preventing static electricity from being introduced and avoiding light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

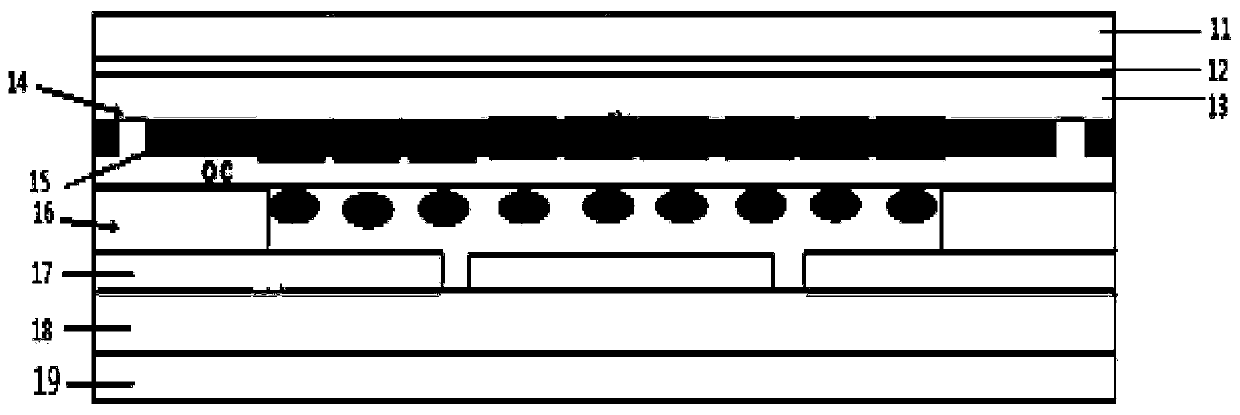

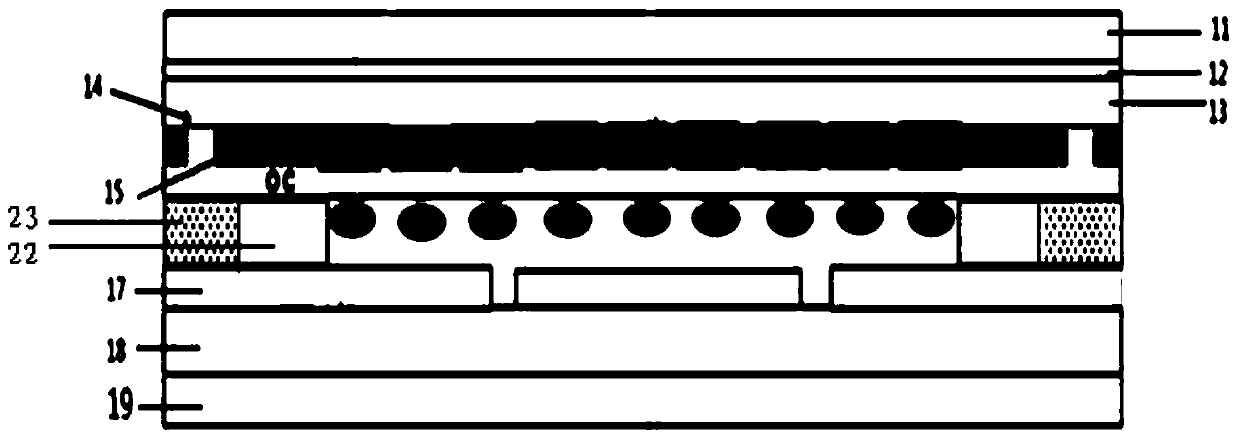

[0031] figure 1 A cross-sectional view of an existing display panel. figure 1 Among them, 11 is the upper polarizer, 12 is the ITO film, 13 is the first substrate, 14 is the black matrix pattern slotting, 15 is the black matrix, 16 is the sealing glue layer, 17 is metal, 18 is the second substrate, 19 For the lower polarizer.

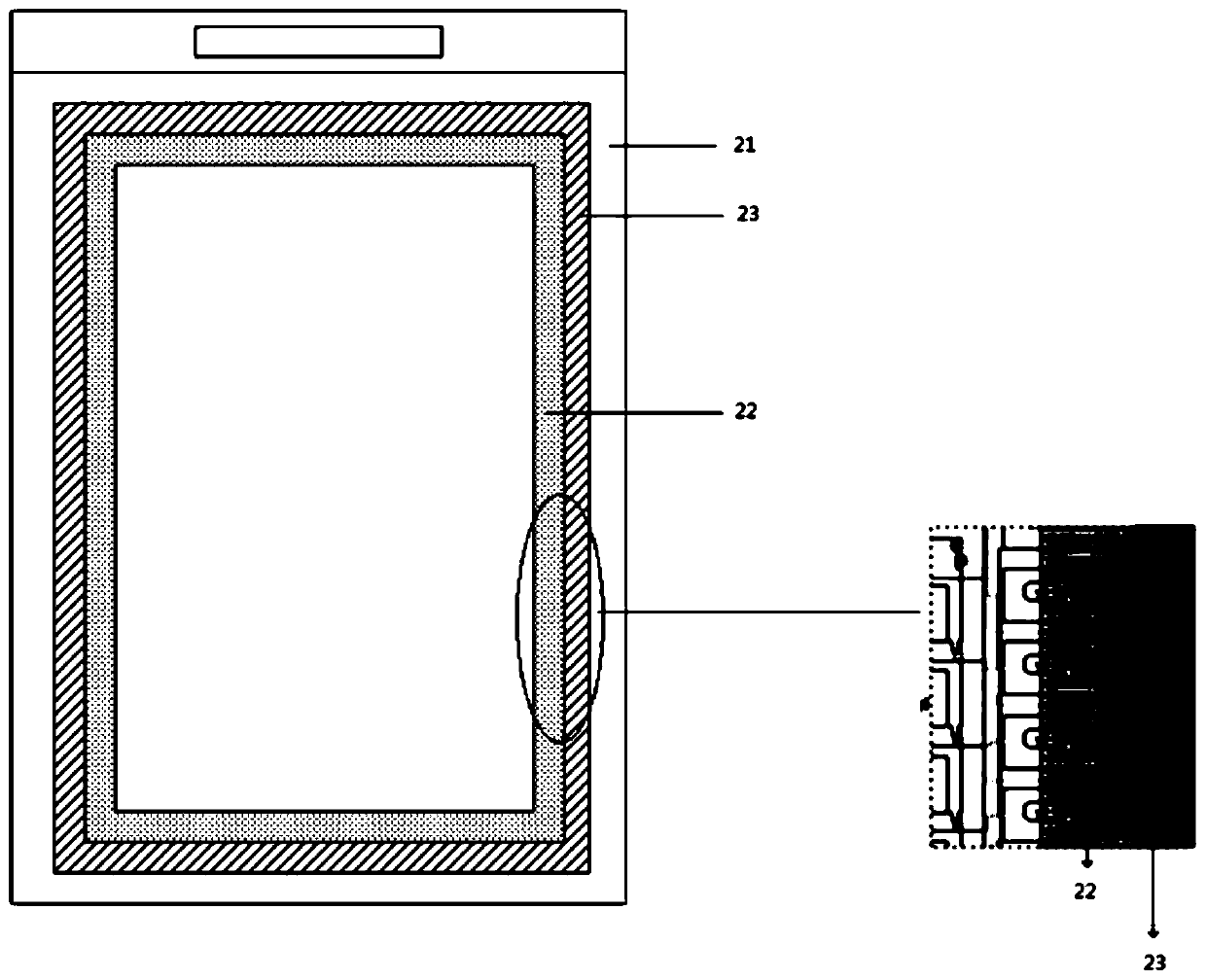

[0032] The invention discloses a display panel, which includes a first substrate and a second substrate arranged in a box, and a sealing glue layer for encapsulating the first substrate and the second substrate together. The first substrate or the second substrate is A black matrix pattern is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com