Preparation of luminescent material

A fluorescent material, gadolinium oxide technology, applied in the direction of luminescent materials, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of easy oxidation of compounds, high melting point of phosphor powder, inability to melt, etc., to achieve luminous brightness and performance improvement, High luminous efficiency and easy industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

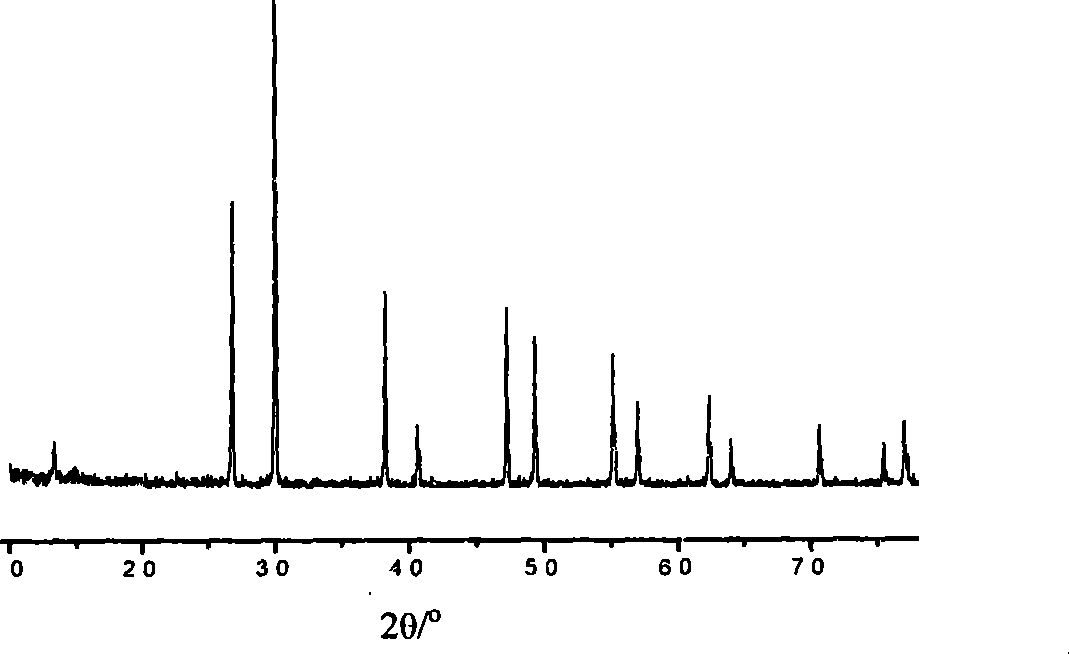

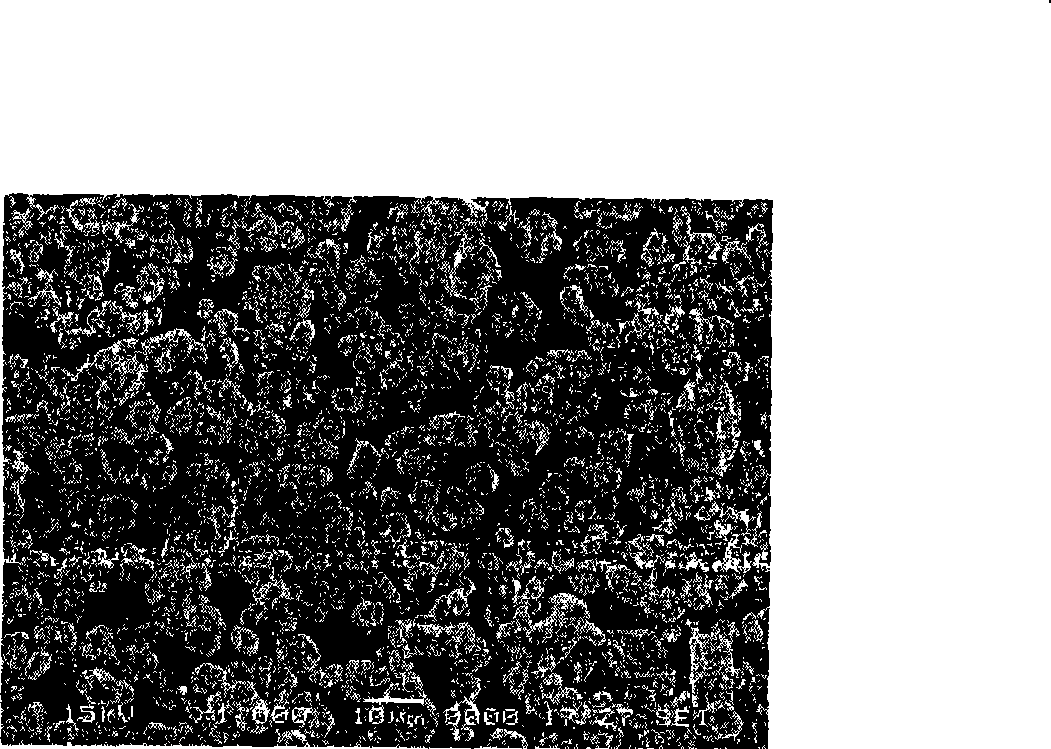

[0023] Embodiment 1: Weighing Gd 2 o 3 has a mass of 17 g, Tb 4 o 7 The quality of 0.15 gram, measure the volume of the nitric acid of 65% that the mass percent concentration is 23mL, and add the water of 20mL simultaneously to above-mentioned Gd 2 o 3 with Tb 4 o 7 In the mixture, continuously stir and heat until the temperature is about 90° C., and configure ammonia water with a concentration of 15 wt%, and adjust the pH value to about 1.5. The quality of taking the oxalic acid crystal is 37.5 grams, add 150mL of water to dissolve, then add oxalic acid to neutralize the nitrate generated by the above steps, carry out coprecipitation reaction, the reaction time is 0.5 hour, obtain the coprecipitate of rare earth oxalate, static Leave for 2.5 hours. Pour out the supernatant and filter with suction, dry it at 100°C for 1 hour, take it out, heat and decompose it at 900°C to obtain the precursor, and keep it for 2 hours. Take out the brown precursor, weigh 17 grams of the...

Embodiment approach 2

[0024] Embodiment 2: Weighing Gd 2 o 3 has a mass of 20 grams, Tb 4 o 7 The mass is 0.25 grams, and the volume of concentrated nitric acid with a mass percentage concentration of 65% is 24mL, and the water of 20mL is added to the above-mentioned Gd at the same time 2 o 3 with Tb 4 o 7 In the mixture, continuously stir and heat until the temperature is about 100° C., and prepare ammonia water with a concentration of 15 wt%, and adjust the pH value to about 2.0. The quality of taking the oxalic acid crystal is 33.4 grams, add 120mL of water to dissolve, then add oxalic acid to neutralize the nitrate generated in the above steps, carry out coprecipitation reaction, the reaction time is 1 hour, obtain the coprecipitate of rare earth oxalate, static Leave for 3 hours. Pour out the supernatant and filter it with suction, dry it at 100°C for 2 hours, take it out, heat and decompose it at 1000°C to obtain the precursor, hold it for 1 hour to obtain the precursor, weigh 20 grams, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com