Mushroom powder rich in vitamin D2, and preparation method and application thereof

A technology for mushroom powder and vitamins, which is applied in the directions of medical preparations, applications, and pharmaceutical formulations containing active ingredients, can solve the problems of low vitamin D content and high by-product content, reduce by-products, and avoid isomerism. effect of bulk impurities or degradation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

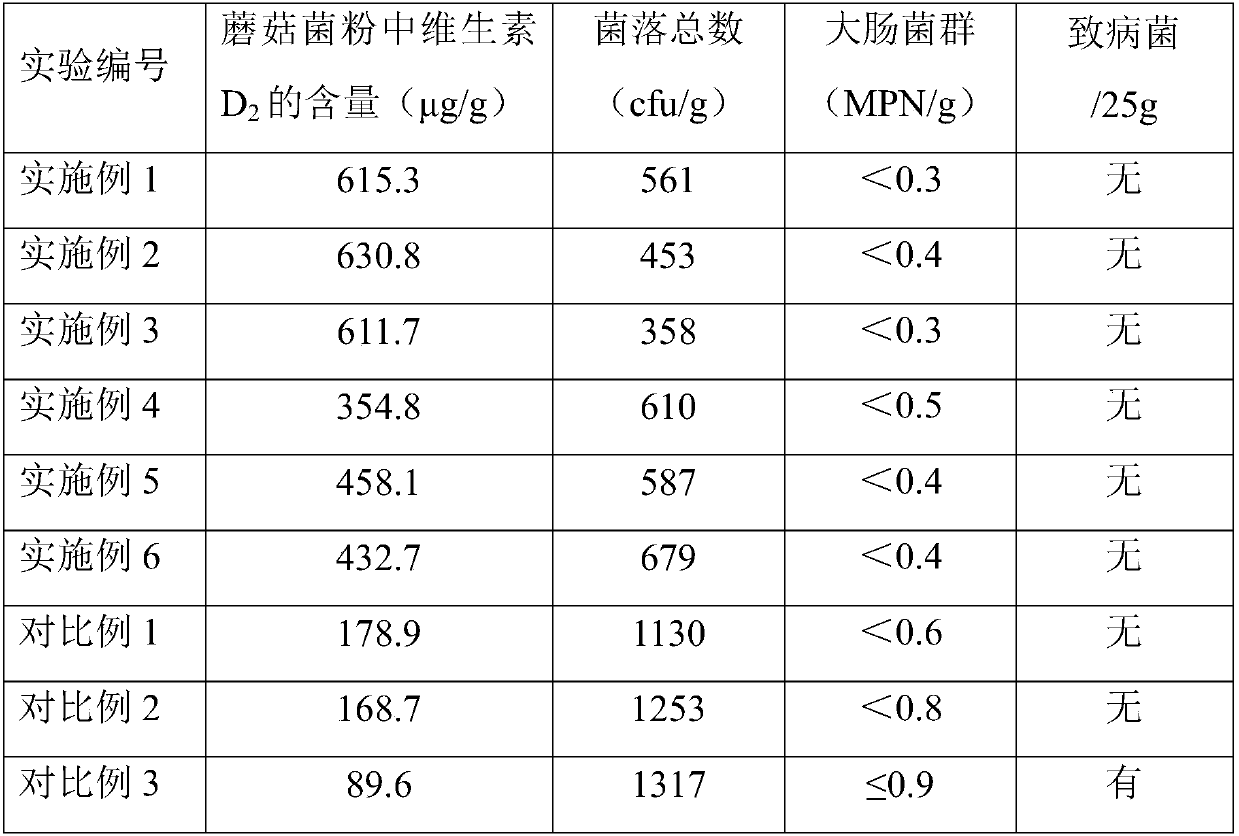

Examples

preparation example Construction

[0023] In a first aspect, the present invention provides a vitamin D-rich 2 The preparation method of the mushroom powder of the present invention comprises: (1) performing ultraviolet light irradiation treatment after mushroom raw material is sliced, and described ultraviolet light irradiation is combined by the UVB irradiation of 280-315nm and the UVC irradiation of 200-280nm, and the ultraviolet light irradiation During the process, the ambient temperature is 20-55° C., the relative humidity of the environment is 50-85%, and the moisture content of the mushroom raw material is not less than 20%; (2) drying the mushroom raw material obtained in step (1) under nitrogen-filled conditions; (3) Pulverizing the mushroom raw material obtained in step (2).

[0024] In the present invention, the mushroom raw material can be one or more of Agaricus bisporus, shiitake mushroom or other mushrooms, and the mushroom raw material needs to be refrigerated and stored in time within 2 days a...

Embodiment 1

[0035] (1) Slicing: the Agaricus bisporus harvested is cleaned after removing foreign matter in the culture medium to obtain the Agaricus bisporus raw material, and the 10kg Agaricus bisporus raw material is taken and cut into thin slices with a thickness of 0.8mm;

[0036](2) Ultraviolet light irradiation: the wavelength is 280nm, and the irradiation dose is 1.5J / cm 2 The UVB irradiates both sides of Agaricus bisporus raw material slices for 180min, and then adopts a wavelength of 200nm and an irradiation dose of 80mJ / cm 2 The UVC irradiates both sides of Agaricus bisporus raw material thin slices for 30 minutes. During the irradiation process, the ambient temperature is 20°C, the relative humidity of the environment is 50%, and the moisture content of Agaricus bisporus raw material is 20%;

[0037] (3) Drying the Agaricus bisporus raw material irradiated by the ultraviolet light in a hot air circulation drying oven under the condition of nitrogen filling, and the drying temp...

Embodiment 2

[0040] (1) Slicing: the Agaricus bisporus harvested is cleaned after removing foreign matter in the culture medium to obtain the Agaricus bisporus raw material, and 10 kg of Agaricus bisporus raw material is taken and cut into thin slices with a thickness of 1.2 mm;

[0041] (2) Ultraviolet light irradiation: the wavelength is 300nm, and the irradiation dose is 4J / cm 2 The UVB irradiates both sides of Agaricus bisporus raw material slices for 100min, and then adopts a wavelength of 240nm and an irradiation dose of 100mJ / cm 2 The UVC is used to irradiate the bisporus raw material slices for 25 minutes on both sides. During the irradiation process, the ambient temperature is 35°C, the relative humidity of the environment is 70%, and the moisture content of the bisporus raw material is 30%;

[0042] (3) Drying the Agaricus bisporus raw material irradiated by the ultraviolet light in a hot air circulation drying oven under a nitrogen-filled condition, and the drying temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com