Nitrogen oxide waste gas treatment method and treatment system thereof

A nitrogen oxide and waste gas treatment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low nitrogen oxide absorption rate, difficult to meet the exhaust emission standards, etc., to achieve less by-products, avoid two The effect of reducing pollution and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

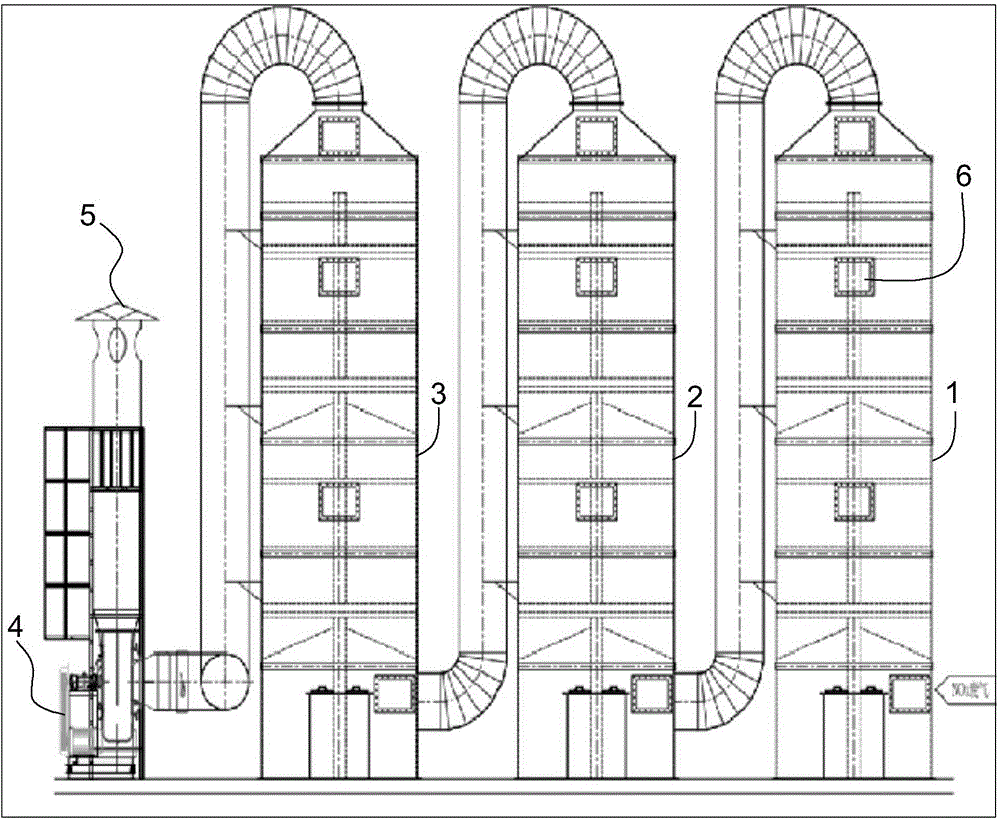

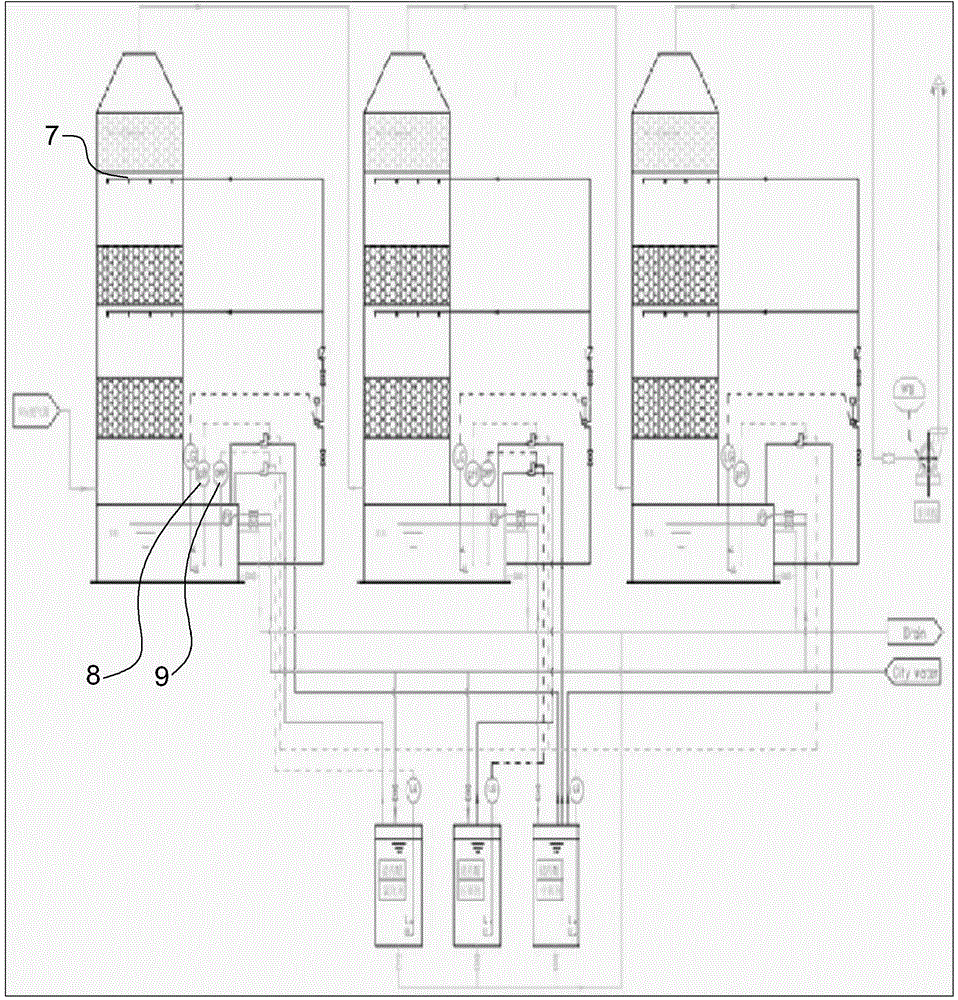

[0024] Such as Figures 1 to 2 As shown, the structure of the exhaust gas treatment system containing nitrogen oxides in this embodiment is mainly composed of a first-stage scrubber 1, a second-stage scrubber 2, a third-stage scrubber 3, and a fan 4 connected in series. The air inlet at the bottom of the first-stage scrubber 1 enters, and the fan 4 is connected with the exhaust port of the third-stage scrubber 3, forming a certain negative pressure in each stage of the scrubber, and at the inlet of the first-stage scrubber 1, the exhaust gas at 5×10 5 It enters the treatment system under Pa pressure, and the treated waste gas tail gas is discharged into the atmosphere through the vent pipe 5 connected with the fan 4 after being tested to meet the discharge standard.

[0025]In this embodiment, the internal structures of the washing towers at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com