Method for preparing cumene hydroperoxide through oxidation of cumene

A technology of propylbenzene hydroperoxide and cumene, which is applied in the direction of preparation of peroxygen compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of low selectivity and no improvement of cumene hydroperoxide To specifically inhibit by-products and other issues, to achieve the effect of inhibiting rightward movement and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

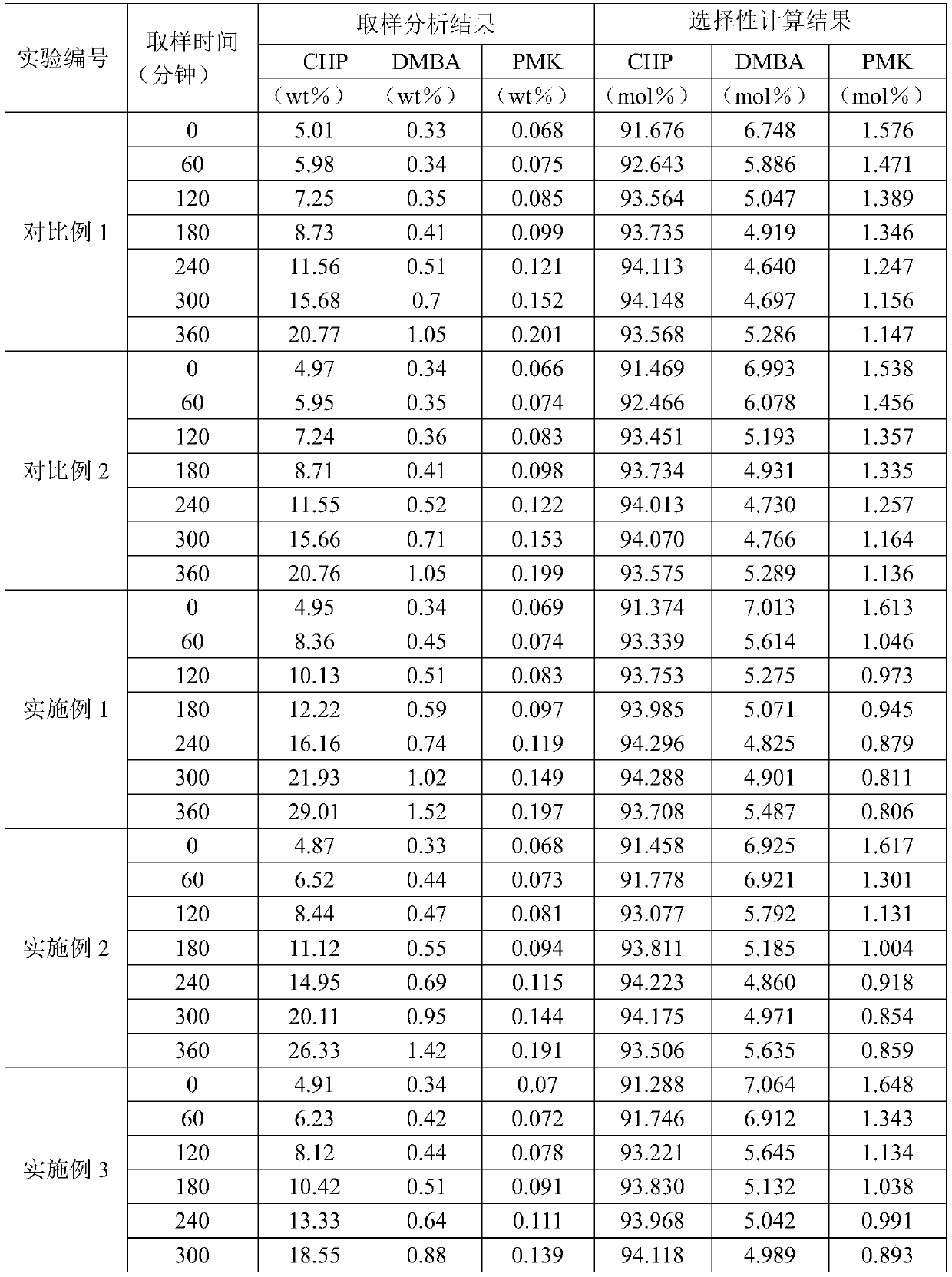

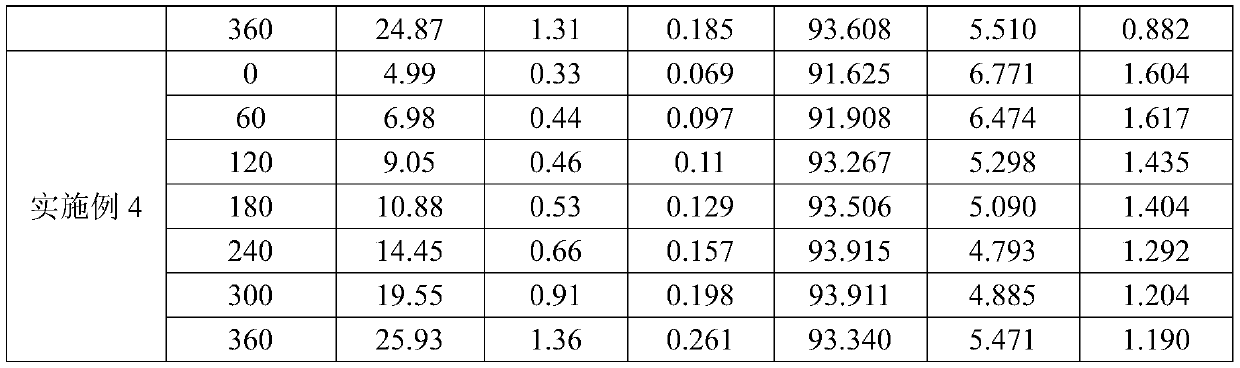

Examples

Embodiment 1

[0057] 1g of 2,4-diphenyl-4-methyl-2-pentene, 7g of by-product inhibitor 1 and 1kg of cumene were added to the reaction kettle, and the rest of the conditions were the same as those of Comparative Example 1.

Embodiment 2

[0059] 5g of 1,1,2-trimethyl-3-phenylindane, 8g of by-product inhibitor 2 and 1kg of cumene were added to the reaction kettle, and the rest of the conditions were the same as those of Comparative Example 1.

Embodiment 3

[0061] 0.02g of cis-1,3-dimethyl-1,3-diphenylcyclobutane, 9g of by-product inhibitor 3 and 1kg of cumene were added to the reaction kettle, and the rest of the conditions were the same as those of Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com