Preparation of composite modified catalyst and method for preparing biological ethane using same

A composite modification and bio-ethylene technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of simple operation process, simple equipment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

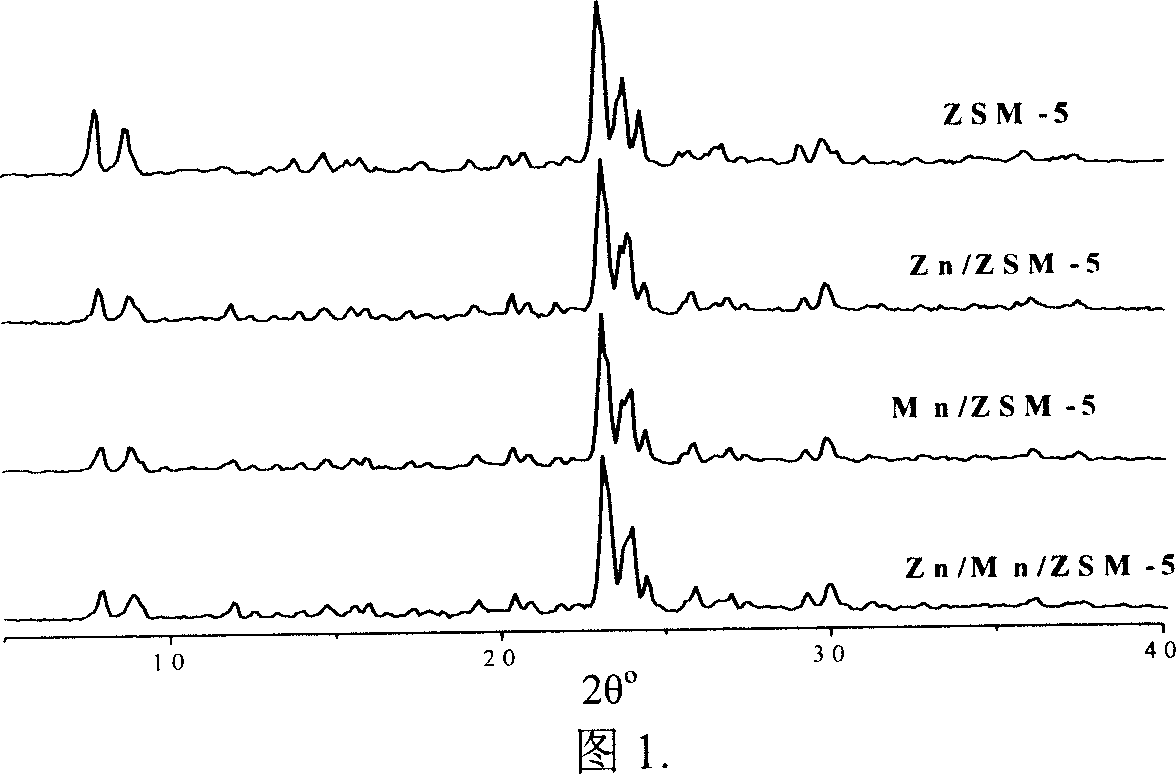

[0019] The invention includes the preparation of the composite modified catalyst and the method for the composite modified catalyst to prepare bio-ethylene. The composite modified catalyst is a solid acid catalyst mainly composed of HZSM-5 molecular sieve. HZSM-5 molecular sieve is used as the original powder, and Zn is respectively introduced by impregnation method. 2+ and Mn 2+ metal ions, then after roasting in a muffle furnace, obtain a composite modified Zn / Mn / ZSM-5 catalyst with higher catalytic activity after tableting, grinding, and sieving;

[0020] The method in which the composite modified catalyst is used to prepare bio-ethylene is to use bio-ethanol as a raw material, and self-prepared composite-modified Zn / Mn / ZSM-5 as a catalyst; in bio-ethanol, add a catalyst, and , feed inert gas, react for a certain period of time at a certain air velocity, reaction space velocity, and reaction temperature; and then obtain bio-ethylene after dehydration, and the conversion r...

Embodiment 1

[0025] The reactor is a fixed bed reactor, and the catalyst is compound modified Zn / Mn / ZSM-5 and unmodified ZSM-5 raw powder. At 400°C, the space velocity is 2.4h -1 When ZSM-5 raw powder catalyzed ethanol dehydration conversion rate was 95.54%, ethylene selectivity was 12.13%; ZSM-5 after complex modification, ethanol dehydration conversion rate was 99.97%, ethylene selectivity was 49.58%. It can be seen that the effect of compound modified ZSM-5 is obviously better than that of the original powder.

Embodiment 2

[0027] Modify the ZSM-5 catalyst with a silicon-aluminum weight ratio of 25, place the original HZSM-5 powder in a Zn-containing 2+ 2wt%, Mn 2+ 4wt% solution, modification time 1h, modification temperature 80°C, calcination temperature 550°C, to obtain composite modified Zn / Mn / ZSM-5 catalyst. In a self-developed fixed-bed reactor, add 4.0g of Zn / Mn / ZSM-5 catalyst at a temperature of 250°C and a space velocity of 1.0h -1 Next, the dehydration experiment was carried out on bioethanol, the ethanol conversion rate was 99.84%, and the ethylene selectivity could reach 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com