Metal palladium nano-material catalyst and preparation and application thereof

A nanomaterial and metal technology, applied in the field of metal palladium nanomaterial catalyst and its preparation, can solve the problems of metal nanocatalysts with large influence on size and morphology, single size high-performance catalysts and the like, and achieves good morphology, single size, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

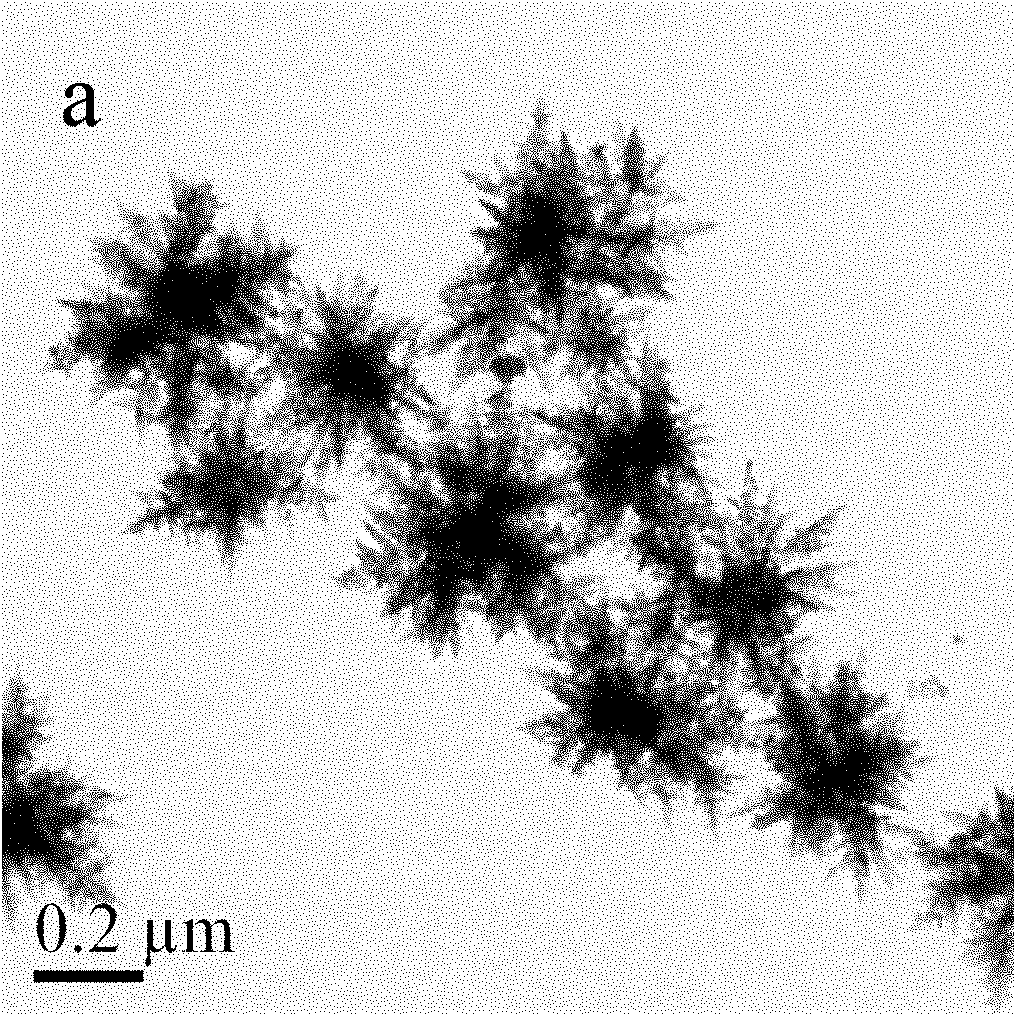

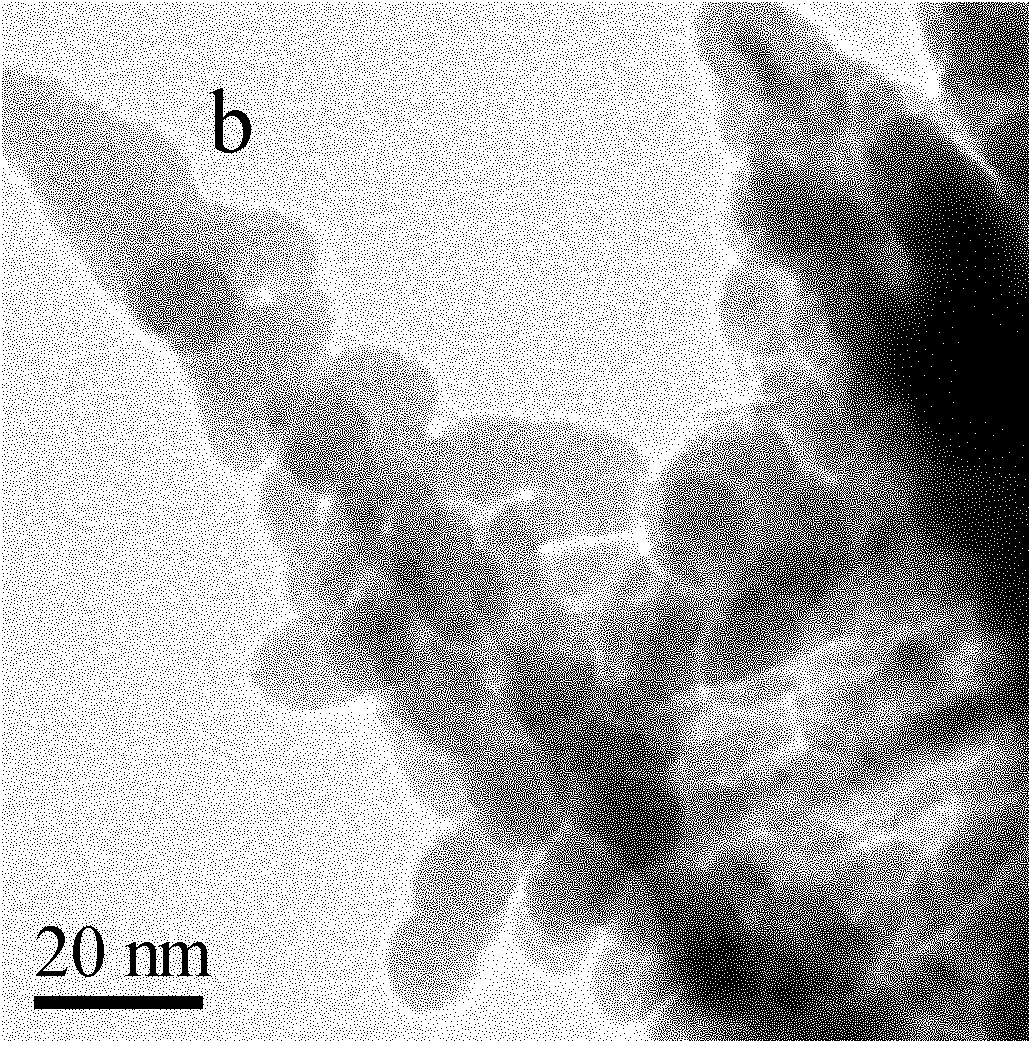

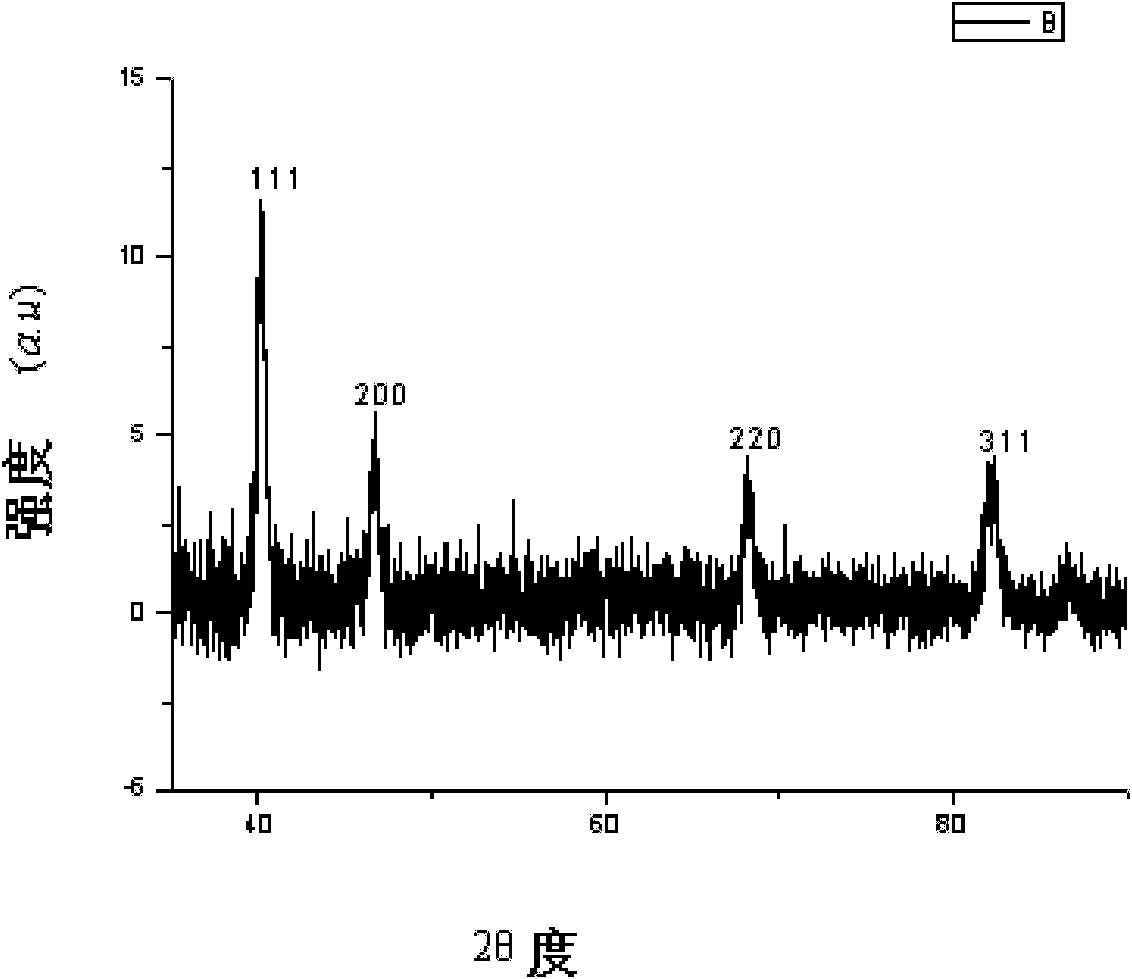

[0025] Accurately weigh a certain amount of PdCl 2 Quickly add twice the amount of PdCl in the Erlenmeyer flask 2 The concentrated hydrochloric acid (37%) of the amount of substance, fully reacts and generates brown-red chloropalladium acid hydrate (H 2 PdCl 4 .nH 2 O). Benzyl alcohol was added to the resulting colloidal solution to prepare 0.03 mol / L of H 2 PdCl 4 benzyl alcohol solution for use. Put 1.0ml 3mmol / L H 2 PdCl 4 -Benzyl alcohol solution, 1.0ml 15mmol / L PVP (in PVP monomer)-benzyl alcohol solution, join in the round bottom flask of 50ml, then add 8.0ml benzyl alcohol again, make the total volume of reaction solution be 10.0ml. Finally, the flask was connected to a microwave oven equipped with a mechanical stirrer (modified, with a structure such as Figure 4 Shown), under the fast stirring of mechanical stirrer, with 100% power (total power is 900W) rapid heating 150s, namely obtain the PVP stable (PVP as dispersant and stabilizer) snowflake palladium nan...

Embodiment 2

[0032] Accurately weigh a certain amount of PdCl 2 Quickly add twice the amount of PdCl in the Erlenmeyer flask 2 The concentrated hydrochloric acid (37%) of the amount of substance, fully reacts and generates brown-red chloropalladium acid hydrate (H 2 PdCl 4.nH 2 O) colloidal solution; Add benzyl alcohol in the colloidal solution of generation, prepare the H of 0.03mol / L 2 PdCl 4 The benzyl alcohol solution is set aside; put 1.0ml 3mmol / L H 2 PdCl 4 -Benzyl alcohol solution, 1.0ml 15mmol / L PVP (in PVP monomer)-benzyl alcohol solution, join in the round bottom flask of 50ml, then add 8.0ml benzyl alcohol again, make the total volume of reaction solution be 10.0ml. Finally, connect the flask to a microwave oven (refitted) equipped with a mechanical stirrer, and heat it with 100% power (total power is 900W) for 150s under rapid stirring of the mechanical stirrer, (following the above conditions, this operation can be reproduced ) to obtain PVP-stabilized (PVP as a disper...

Embodiment 3

[0039] Accurately weigh a certain amount of PdCl 2 Quickly add twice the amount of PdCl in the Erlenmeyer flask 2 The concentrated hydrochloric acid (37%) of the amount of substance, fully reacts and generates brown-red chloropalladium acid hydrate (H 2 PdCl 4 ·nH 2 O) colloidal solution; Add benzyl alcohol in the colloidal solution of generation, prepare the H of 0.03mol / L 2 PdCl 4 benzyl alcohol solution for use. Put 1.0ml 3mmol / L H 2 PdCl 4 -Benzyl alcohol solution, 1.0ml 15mmol / L PVP (in PVP monomer)-benzyl alcohol solution, join in the round bottom flask of 50ml, then add 8.0ml benzyl alcohol again, make the total volume of reaction solution be 10.0ml. Finally, connect the flask to a microwave oven (refitted) equipped with a mechanical stirrer, and heat it with 100% power (total power is 900W) for 150s under rapid stirring of the mechanical stirrer, (following the above conditions, this operation can be reproduced ), obtain PVP stable (PVP as dispersant and stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com