A kind of solid polymer electrolyte containing titanium oxygen cluster, preparation method and application

A solid polymer, polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, batteries, etc., can solve the problems of nanoparticle size, shape non-uniformity, battery performance uncertainty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above solid polymer electrolyte, the steps are as follows:

[0048] A. Add dehydrated glycerol to the dichloromethane solution of CTOC, react at room temperature, and the adverse solvent of CTOC is added such as diethyl ether, and the intermediate product CTOC-PEO is obtained.

[0049] B. The intermediate product CTOC-PEO is dissolved in N, N-dimethylformamide solvent, and the end group is an amino group polyethylene glycol NH. 2 -PEG-NH 2 The reaction was prepolymerized at 50 ° C for 2 to 3 hours to obtain a viscous prepolymer;

[0050] C. Apply the prepolymer to a flat glass substrate to heat the reaction in a vacuum drying tank for 5 to 8 hours to obtain a solid solid polymer diaphragm.

[0051] D. Cut the solid-state polymer diaphragm is circular, soaked in a lithium ion electrolyte 12 to 24 hours to obtain a solid polymer electrolyte.

[0052] Preferably, the step of separating the purification in step A is: EtOAc (EtOAc) EtOAc.

[0053] P...

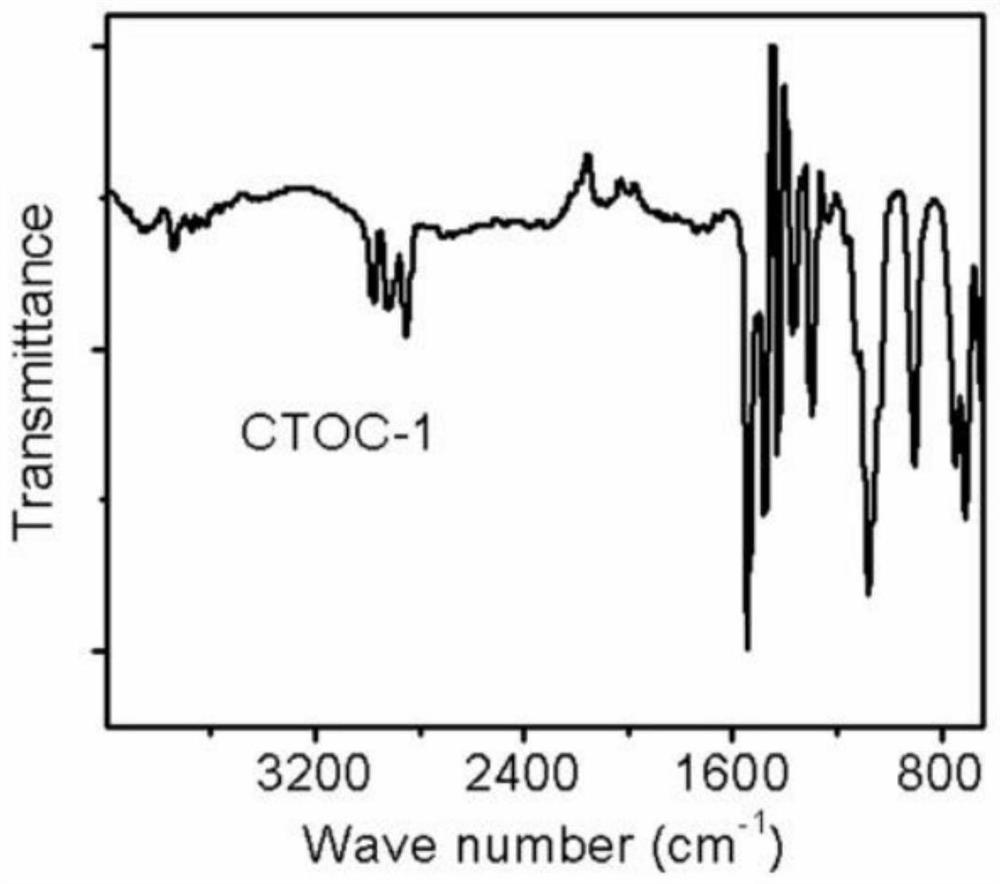

Embodiment 1

[0063] The synthetic route of the synthesized solid polymer electrolyte synthesized by the present invention is as follows:

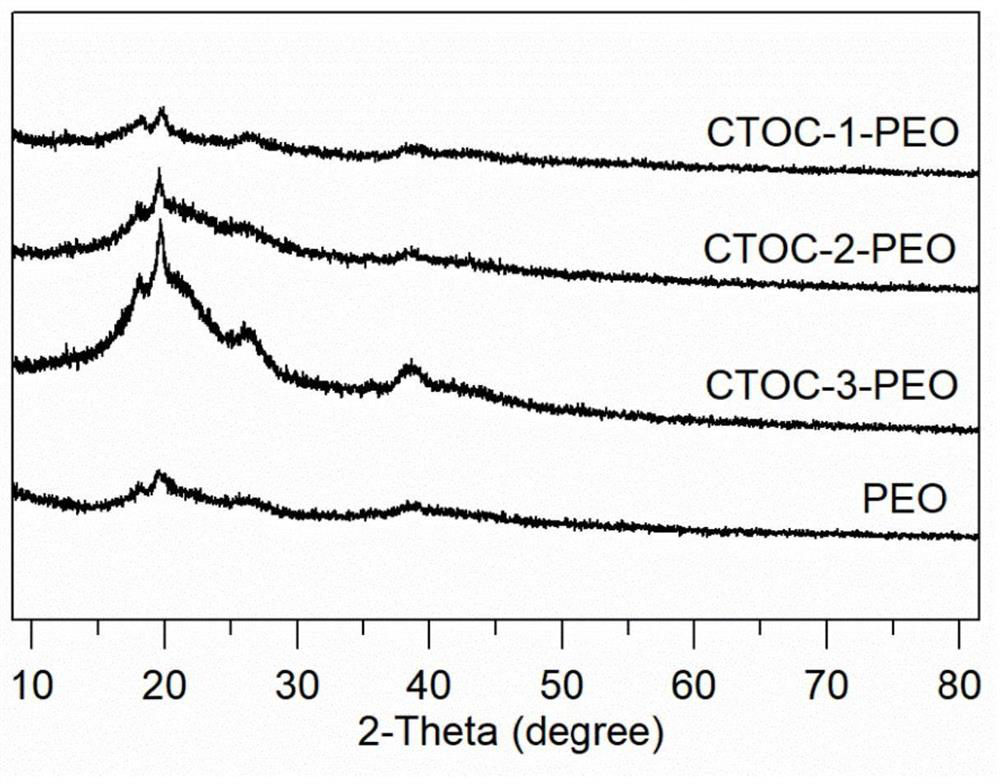

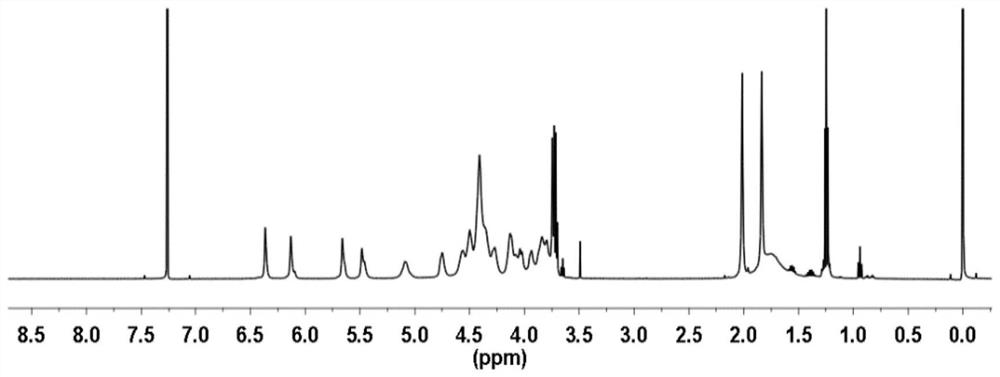

[0064] 1, CTOC-1-PEO preparation:

[0065] CTOC-1 (200 mg, 36 mmol) was dissolved in 5 mL of dichloromethane, concentration of 40 mg ml -1 3 ml of dehydrated glycerol, shake uniform, and allowed to react for 12 hours. 60 mL of diethyl ether was added to the system, there will be a large amount of white precipitation, and the deposition is not increased, centrifuged, washed twice with tetrahydrofuran, and dry the white intermediate CTOC-1-PEO.

[0066] 2, preparation of the prepolymer

[0067] The intermediate product CTOC-1-PEO (50 mg) is dissolved in N, N-dimethylformamide (5 mL), and the end group is an amino group polyethylene glycol NH. 2 -PEG-NH 2 (Molecular Weight: 1000d, 130 mg), at 50 ° C, prepolymerized 2.5 hours, resulting in viscous prepolymer CTOC-1-PEO-PEG.

[0068] 3, preparation of solid polymer diaphragm

[0069] The viscous prepolymer CTOC-...

Embodiment 2

[0073] 1, CTOC-2-PEO preparation:

[0074] CTOC-2 (200 mg, 32 mmol) was dissolved in 5 ml of dichloromethane, concentration of 40 mg ml -1 3 ml of dehydrated glycerol, shake uniform, and allowed to react for 12 hours. 60 mL of diethyl ether was added to the system, there will be a large amount of white precipitation, and the deposition is not increased, centrifugally separated, washed twice with tetrahydrofuran, vacuum drying. CTOC-2-PEO.

[0075] 2, preparation of the prepolymer

[0076] The intermediate product CTOC-2-PEO (50 mg) is dissolved in N, N-dimethylformamide (5 mL), and the end group is an amino group polyethylene glycol NH. 2 -PEG-NH 2 (Molecular Weight: 1000D, 130 mg), at 50 ° C, prepolymerization of 2.5 hours, resulting in viscous prepolymer CTOC-2-PEO-PEG.

[0077] 3, preparation of solid polymer diaphragm

[0078] The viscous prepolymer CTOC-2-PEO-PEG was applied to a flat glass substrate, placed in a vacuum drying tank and continued to react for 6 hours, cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com