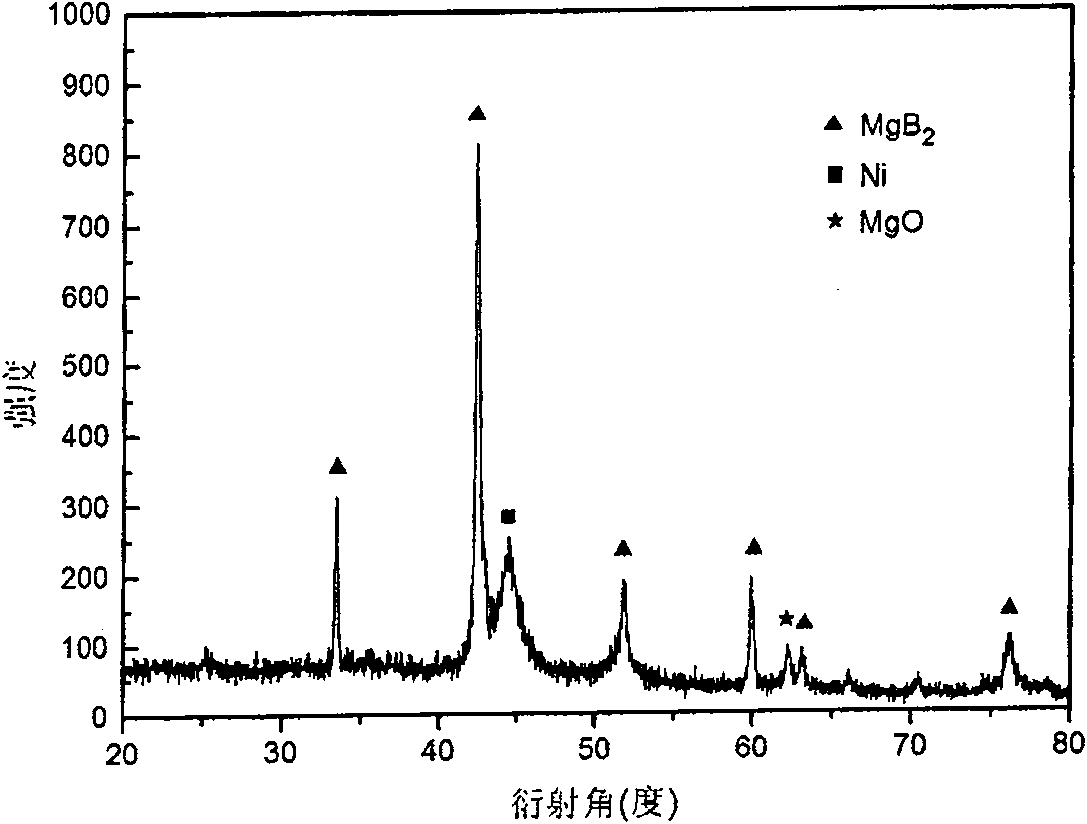

Method for in-situ preparation of carbon coated nickel-particle doped MgB2 superconductive material

A technology of carbon-coated nickel and in-situ preparation, applied in the field of superconductivity, to achieve the effect of uniform distribution of nanoparticles, simple method, and high critical current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

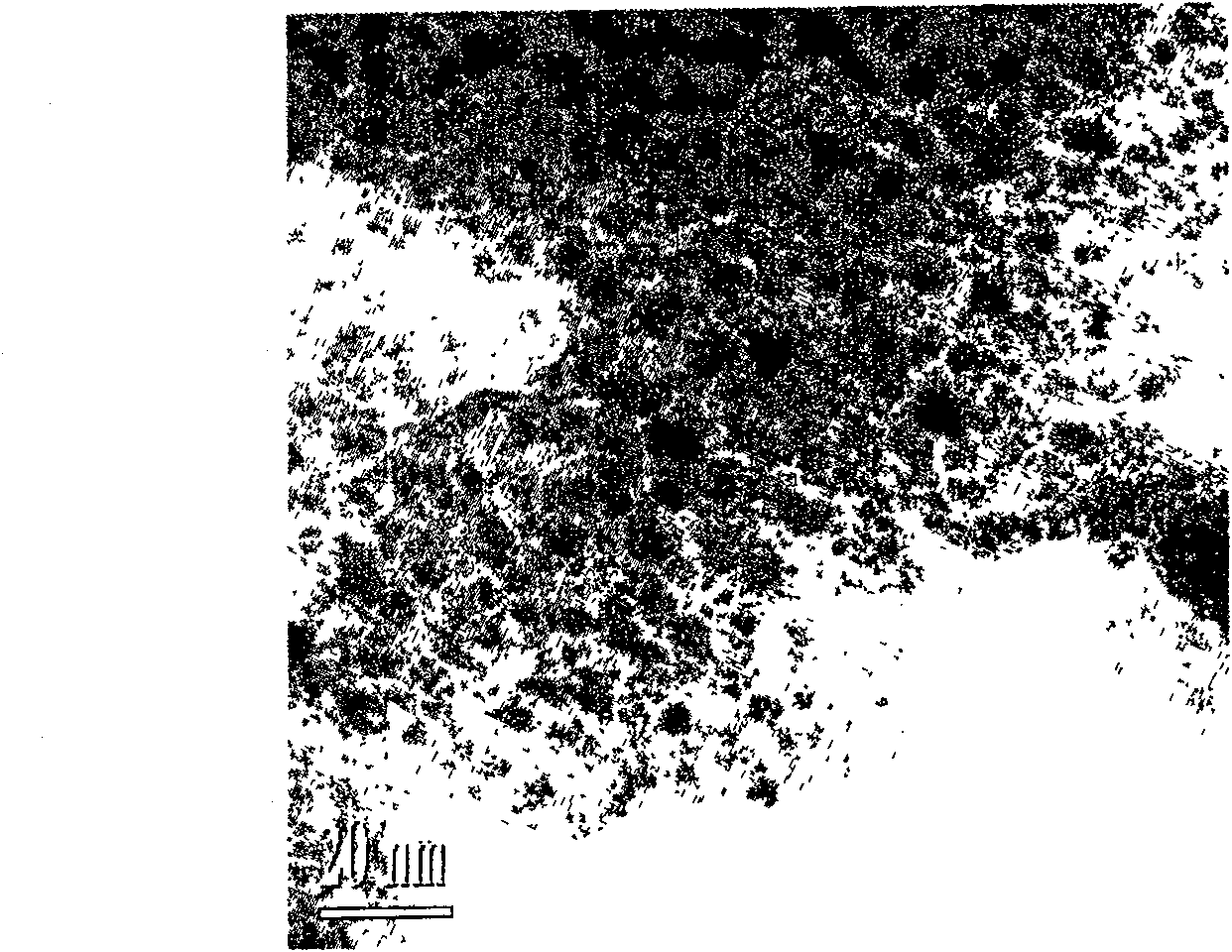

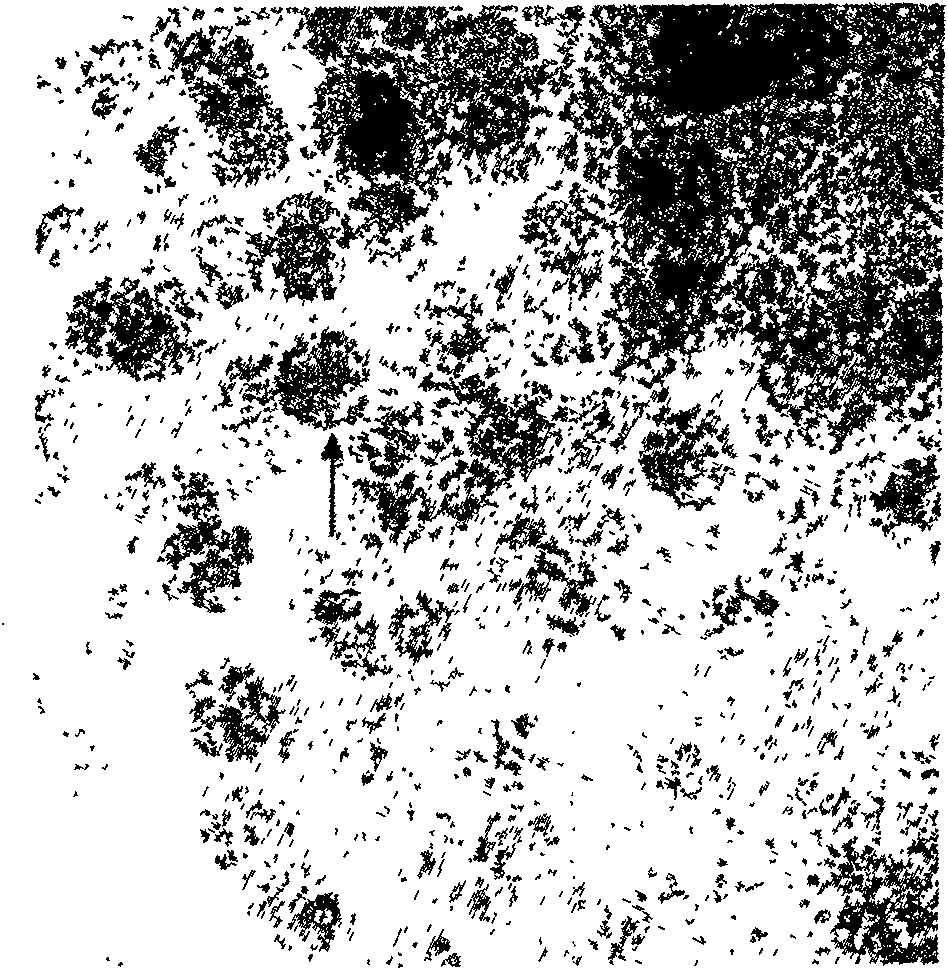

Embodiment 1

[0022] An in-situ preparation of carbon-coated nickel particles doped with MgB 2 The method of superconducting material, is made up of following steps: with MgB 2 :Ni Weigh MgB in a ratio of 4:1 by weight 2 powder and Ni(NO 3 ) 2 ·6H 2 O powder is the raw material, pour the weighed powder into a large beaker, and pour distilled water 50 times the weight of the raw material at the same time, put the beaker in a magnetic stirrer to stir, and titrate with NaOH solution, the reaction that occurs during this process for:

[0023] Ni(NO 3 ) 2 ·6H 2 O+2NaOH=Ni(OH) 2 (precipitation)+2NaNO 3 ;

[0024] After titration, place the beaker at room temperature for precipitation for 5 hours, separate the precipitate from the aqueous solution, pour out the remaining aqueous solution, and remove the precipitated substance MgB 2 and Ni(OH) 2 Dry in a drying oven to remove excess moisture, then put the precipitate into a tube furnace, and calcinate at 400°C for 2 hours under the prot...

Embodiment 2

[0030] An in-situ preparation of carbon-coated nickel particles doped with MgB 2 The method of superconducting material, is made up of following steps: with MgB 2 :Ni Weigh MgB at a weight ratio of 19:1 2 powder and Ni(NO 3 ) 2 ·6H 2 O powder is the raw material, pour the weighed powder into a large beaker, and pour distilled water 50 times the weight of the raw material at the same time, place the beaker on a magnetic stirrer, and titrate with KOH solution (other alkalis can also be used) After the titration, place the beaker at room temperature for precipitation for 3 hours, separate the precipitate from the aqueous solution, pour out the remaining aqueous solution, dry the precipitate in a drying oven to remove excess water, and then put it into the tube In the furnace, under the protection of nitrogen, it was calcined at 400 ° C for 2 hours and then lowered to room temperature, and then the calcined material was passed into H in a tube furnace. 2 , the flow rate is 10...

Embodiment 3

[0032] An in-situ preparation of carbon-coated nickel particles doped with MgB 2 The method of superconducting material, is made up of following steps: with MgB 2 :Ni Weigh MgB in a ratio of 4:1 by weight 2 powder and Ni(NO 3 ) 2 ·6H 2 O powder is the raw material, pour the weighed powder into the container, and pour distilled water equivalent to 40 times the weight of the raw material at the same time, stir, and titrate with NaOH solution. After the titration, put the container at room temperature to settle for 12 hours. , to separate the precipitate from the aqueous solution, pour out the remaining aqueous solution, dry the precipitate in a drying oven to remove excess water, put the precipitated material into a tube furnace, and calcinate at 400°C for 2 hours and then cool down to room temperature under the protection of nitrogen. , and then the calcined substance was passed into H in a tube furnace 2 , the flow rate is 15L / min, then heat up to 500°C and hold for 1h, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com