Modified high-voltage positive electrode material and preparation method and application thereof

A positive electrode material, high voltage technology, applied in the direction of active material electrodes, positive electrodes, battery electrodes, etc., can solve the problems of easy erosion, increase of lithium ion transmission impedance, dissolution of surface active substances, etc., achieve uniform and controllable growth, promote Development and application, the effect of excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

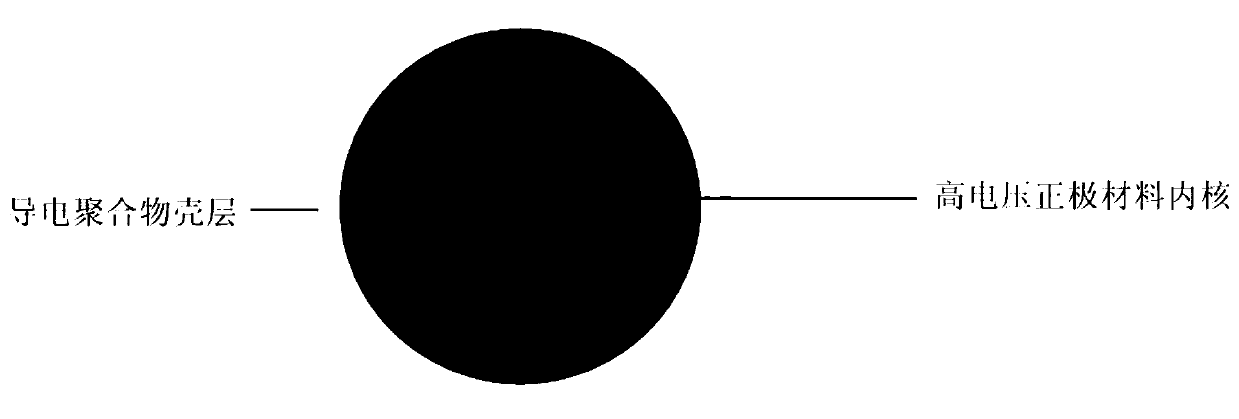

[0063] A modified high-voltage cathode material of the present invention, comprising a high-voltage cathode material core and a conductive polymer shell coated on the surface of the high-voltage cathode material core, such as figure 1 as indicated. In this embodiment, the high-voltage positive electrode material is a lithium-rich solid solution positive electrode material, and the conductive polymer is a polythiophene derivative PEDOT:PSS.

[0064] In this embodiment, the general formula of the lithium-rich solid solution positive electrode material is expressed as follows:

[0065] z 1 Li 2 MnO 3 ·(1-z 1 )LiNi x1 mn y1 co (1-x1-y1) o 2 (x 1 =0.2,y 1 = 0.6, z 1 = 0.4).

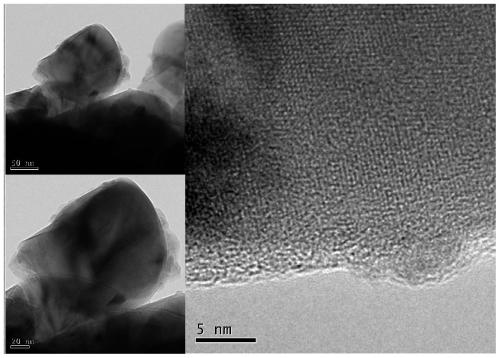

[0066] In this embodiment, the thickness of the conductive polymer material is between 0.002 μm and 0.01 μm, and the thickness of the conductive polymer shell layer can be regulated by changing the amount of the polymer.

[0067] A preparation method of the modified high-voltage cathode material o...

Embodiment 2

[0080] A modified high-voltage cathode material of the present invention, comprising a high-voltage cathode material core and a conductive polymer shell coated on the surface of the high-voltage cathode material core, such as figure 1 as indicated. In this embodiment, the high-voltage positive electrode material is a lithium-rich solid solution positive electrode material, and the conductive polymer is a polythiophene derivative PEDOT.

[0081] In this embodiment, the general formula of the lithium-rich solid solution positive electrode material is expressed as follows:

[0082] z 1 Li 2 MnO 3 ·(1-z 1 )LiNi x1 mn y1 co (1-x1-y1) o 2 (x 1 =0.2,y 1 = 0.5, z 1 = 0.4).

[0083] In this embodiment, the thickness of the conductive polymer material is 0.002 μm˜0.01 μm.

[0084] A preparation method of the modified high-voltage cathode material of the present embodiment, comprising the following steps:

[0085] (1) configure the mixed solution containing conductive polym...

Embodiment 3

[0098] A modified high-voltage cathode material of the present invention, comprising a high-voltage cathode material core and a conductive polymer shell coated on the surface of the high-voltage cathode material core, such as figure 1as indicated. In this embodiment, the high-voltage positive electrode material is a high-voltage nickel-manganese spinel positive electrode material, and the conductive polymer is a polythiophene derivative PEDOT:PSS.

[0099] In this embodiment, the general formula of the high-voltage nickel-manganese spinel positive electrode material is expressed as:

[0100] LiNi x mn 2-x o 4 (x=0.5).

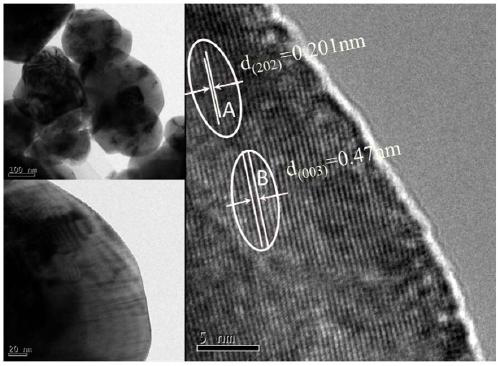

[0101] In the high-voltage positive electrode material of this embodiment, the high-voltage nickel-manganese spinel positive electrode material (ie, the core material) is granular, and is a nano-scale positive electrode material synthesized by the sol-gel method, and the thickness of the conductive polymer shell is 0.002 μm ~0.01 μm.

[0102] A preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com