Cane sugar manufacture production system

A production system and sugarcane technology, applied in the fields of sucrose production, sugar production, and sucrose extraction, can solve the problems of low purity of cane juice, low production efficiency, and restrictions on the development of sugar-making enterprises, so as to reduce equipment investment and operating costs, Reduce investment and production costs and realize the effect of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

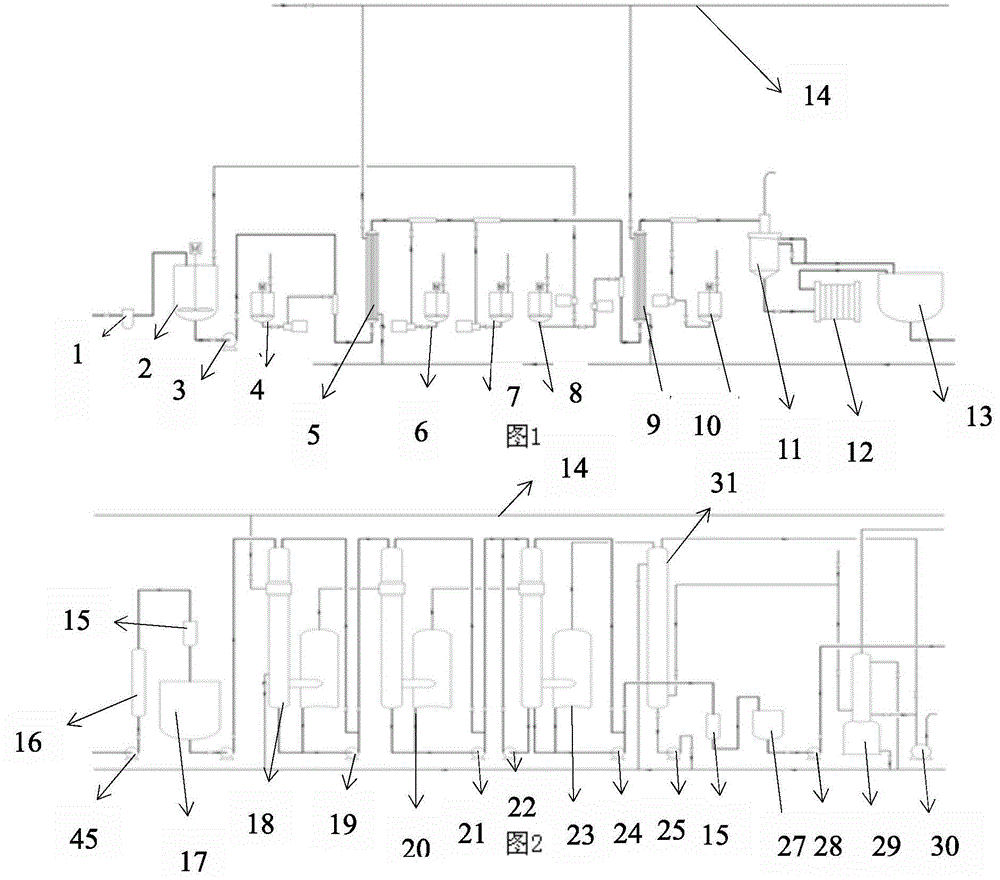

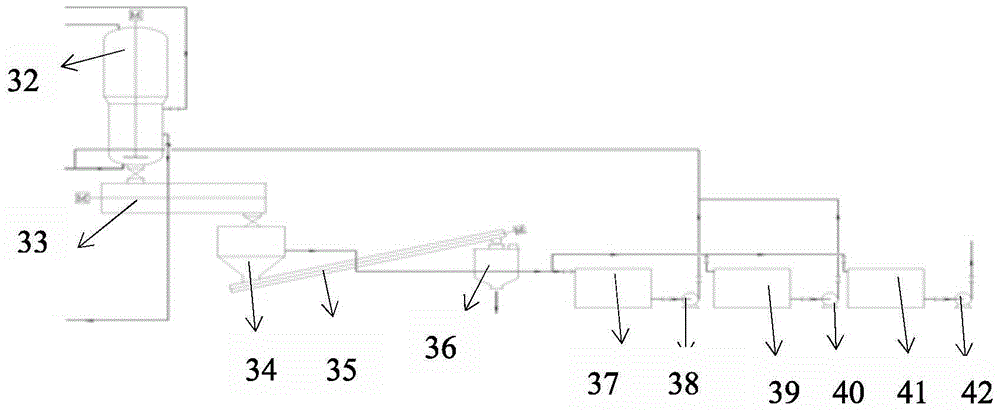

[0018] Such as figure 1 , figure 2 and image 3 As shown, the sugarcane sugar production system mainly includes a cleaning system, and the cleaning system includes a pipeline filter, a mixed juice tank, a mixer, a primary heater, a secondary heater, a rapid sedimentation tank, a filter press, and a juice cleaning tank. The pipeline filter is connected to the upper part of the mixed juice tank through a pipeline, and a mixed juice pump is arranged at the bottom outlet of the mixed juice tank; the bottom of the primary heater is connected to the mixer through a pipeline and then connected to the mixed juice pump, and A pipeline is branched from the middle mixer to connect with the storage tank provided with a metering pump; the bottom of the secondary heater is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com