Sugar juice air-float clearing method

A clean and air flotation technology, applied in the purification of sugar juice, sugar production, sucrose production, etc., can solve the problems that hinder the implementation and promotion of low-temperature phosphorus flotation technology, affect the decolorization effect of flotation, and the unsatisfactory foam making effect, etc., to achieve It is not easy to accumulate fermentation, reduce the intensity of sulfur fumigation, and ensure the quality of finished sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

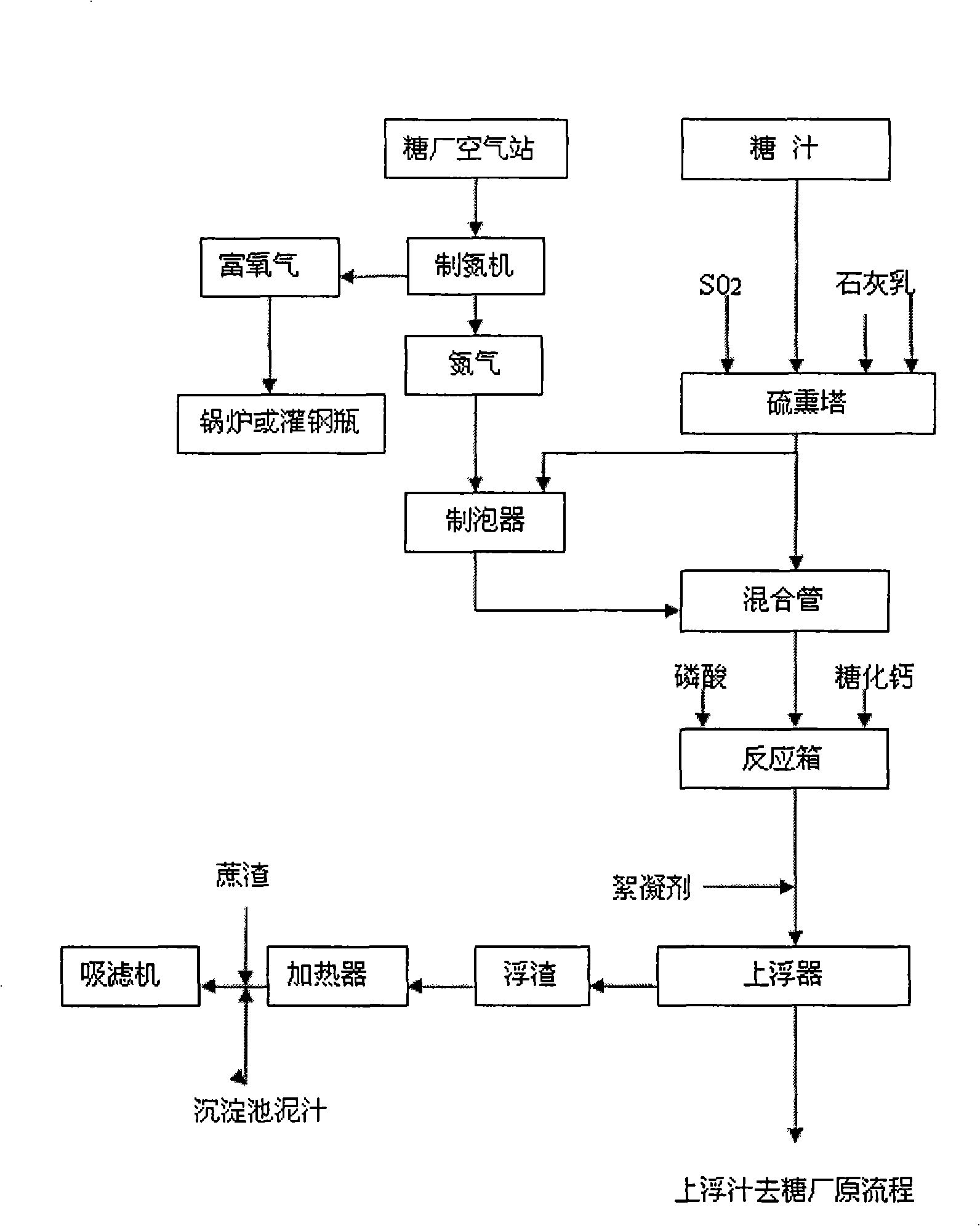

[0025] Embodiment 1, to the floating processing method of mixed juice, its flow process is as follows:

[0026] Add phosphoric acid (50-150PPM) and lime milk to the mixed juice, control the pH value at 6.8-7.8, and heat it (50-65°C) before entering the sulfur fumigation tower; add a small amount of sulfur dioxide, carbon dioxide and lime to the sulfur fumigation tower Milk, carry out a mild sulfur fumigation neutralization and mild carbon dioxide saturation (PH value is controlled at 7.2-7.8, sulfur fumigation intensity is controlled at 5-8); most of the mixed juice after the first sulfur fumigation neutralization directly enters the floater Others (10-30%) are added polyaluminum chloride (10-20PPM) and then enter the bubble maker with more than 99% nitrogen as the gas source, and then enter the mixing tube; add flocculant ( 1-3PPM), and then the mixed juice in the mixing tube is sent to the floating device for separation treatment, and the floating clear juice with lower colo...

Embodiment 2

[0027] Embodiment 2, to the floating processing method of neutralizing juice, its flow process is as follows:

[0028]Most of the neutralized juice from the neutralizer is directly sent to the mixing tube of the floater, and the rest (10-30%) is added to polyaluminum chloride (10-20PPM) and then enters the system with more than 99% nitrogen as the gas source. Then enter the mixing tube; add cationic flocculant (1-3PPM) into the mixing tube, and then send the neutralized juice in the mixing tube to the floater for separation treatment, so as to obtain the floating clear juice with lower color value. The floating clear juice is pre-ashed twice to adjust the pH value to 7.0-7.3 by adding phosphoric acid, and then enters the original process of the next sugar factory; the scum is added with part of cane bran, and after heating, it is mixed with the sludge in the sedimentation tank and sent to the suction filter for filtration.

Embodiment 3

[0029] Embodiment 3, to the floating processing method of clear juice of sedimentation tank, its flow process is as follows:

[0030] In the clear juice of the slightly alkaline sedimentation tank (PH7.3-8.0), add phosphoric acid to adjust the pH value to 7.0-7.2, and then most of them directly enter the mixing tube of the floater, and add polyaluminium chloride to the others (10-30%) (5-20PPM) and then enter the bubble maker with more than 99% nitrogen as the gas source, and send it into the mixing tube; add flocculant (1-3PPM) into the mixing tube, and then send the clear juice of the sedimentation tank in the mixing tube into the floating Separation treatment by the device can obtain the supernatant juice with lower color value. The floating clear juice enters the original process of the next sugar factory; the floating slag is added with part of cane bran, mixed with the sludge in the sedimentation tank and sent to the suction filter for filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com