Membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology

A technology for refining sugar and membrane technology, which is applied in the field of refining sugar and clarified syrup removing impurities and decolorization process, can solve the problems of high investment and operation cost, complicated brine post-treatment process, and aggravated sucrose reducing sugar decomposition, etc., and achieves investment cost and operation cost. Low cost, beneficial to crystallization, and the effect of reducing color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The basic parameters of clarified syrup are as follows:

[0018] Brix °Bx

Simple purity %

Color value IU

Turbidity NTU

Conductivityus / cm

50.3

98.74

469

4.23

115

[0019] The clarified syrup was sampled from the clarified syrup after press filtration, before going to evaporation.

[0020] Transport the clarified syrup to a microfiltration device with a pore size of 0.45 μm, the pressure is 0.15 MPa, the temperature of the clarified syrup is 45 ° C, and the pH of the clarified syrup is 7.2 to obtain a microfiltration concentrate and a microfiltration permeate, and remove the microfiltration concentration liquid, leaving the microfiltration permeate.

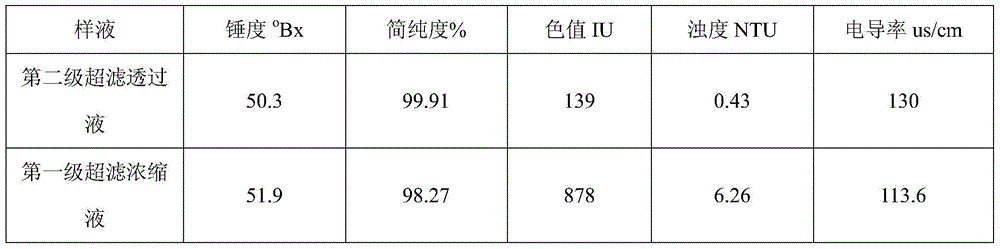

[0021] The microfiltration permeate is transported to the ultrafiltration device, the molecular weight cut-off of the first stage ultrafiltration is 10,000 Daltons, the pressure is 1.8MPa, the temperature of the microfiltration permeate is 45°C, and the pH of the microf...

Embodiment 2

[0027] The basic parameters of clarified syrup are as follows:

[0028] Brix °Bx

[0029] The clarified syrup was sampled from the clarified syrup after press filtration, before going to evaporation.

[0030] The clarified syrup is transported to a microfiltration device with a pore size of 0.8 μm, the pressure is 0.10 MPa, the temperature of the clarified syrup is 75 ° C, and the pH of the clarified syrup is 7.8 to obtain a microfiltration concentrate and a microfiltration permeate, and remove the microfiltration concentration liquid, leaving the microfiltration permeate.

[0031] The microfiltration permeate is transported to the ultrafiltration device, the molecular weight cut-off of the first stage ultrafiltration is 10,000 Daltons, the pressure is 1.8MPa, the temperature of the microfiltration permeate is 75°C, and the pH of the microfiltration permeate is 7.8 , recover 75% of the first-stage ultrafiltration permeate, 25% of the first-stage ultrafiltration conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com