VGF/VB gallium arsenide single-crystal furnace structure and growing method

A growth method and technology of gallium arsenide, applied in the field of semiconductor material preparation, can solve problems such as disadvantages, and achieve the effects of preventing deformation, increasing crystallization rate, and improving degree of depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

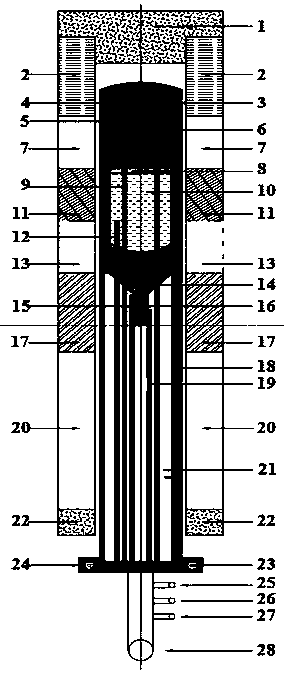

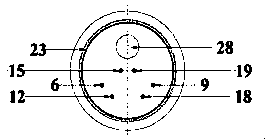

[0044] Embodiment 1: 4-inch carbon-doped semi-insulating gallium arsenide single crystal growth.

[0045] The quartz tube 3 used had an inner diameter of 130 mm, a thickness of 8 mm, and a length of 120 mm.

[0046] First load ) crystal orientation seed crystal, then load 80g of boron oxide with water content less than 200ppm, and then load D-type gallium arsenide polycrystal synthesized by horizontal method or gallium arsenide with a diameter of 100mm synthesized by high-voltage VGF Polycrystalline 8.3±0.1kg. Then place it on the graphite support base 21, cover the quartz tube 3, seal the quartz tube 3 and the stainless steel flange 24 with water cooling. With water-cooled stainless steel flange 24, the external six monitoring thermocouple quick-plug connectors are connected to the compensation wires of the temperature control system, connected to the flange for circulating cooling water, vacuuming and inflation and deflation pipelines, in manual mode, lift with water-cooled...

Embodiment 2

[0053] Embodiment 2: The differences between this embodiment and Embodiment 1 are: (1) 4-inch Si-doped low-resistance gallium arsenide single crystal growth. First load the crystal orientation seed crystal, then load 80g of boron oxide with a water content less than 200ppm, and then load D-type gallium arsenide polycrystal synthesized by horizontal method or gallium arsenide polycrystal with a diameter of 100mm synthesized by high-voltage VGF 10 ±0.3kg, loaded with 1±0.05g of silicon chip with resistivity above 1000Ω•cm. (2) After vacuuming, only fill with argon to 0.35MPa. (3) The VB growth stroke is 200mm for the crystal. (4) VB drop speed 2.0mm / h.

[0054] Cut a test piece from the crystal head to tail to test the low resistance GaAs carrier concentration, resistivity and dislocation density. The test crystal head and tail parameters are shown in Table 2.

[0055] Table 2

[0056] Diameter control (mm)

Embodiment 3

[0057] Embodiment 3: The difference between this embodiment and Embodiment 1 is: (1) A 6-inch growth single crystal furnace consisting of a graphite support base, a quartz tube and a water-cooled stainless steel flange is used to grow a 6-inch carbon-doped semi-insulating arsenic Gallium single crystal. The quartz tube 3 used had an inner diameter of 179 mm, a thickness of 10 mm, and a length of 120 mm. (2) First load ) crystal orientation seed crystal, then load 150g of boron oxide with water content less than 200ppm, and then load D-type gallium arsenide polycrystal synthesized by horizontal method or gallium arsenide with a diameter of 150mm synthesized by high-voltage VGF Polycrystalline 16±0.1kg. (3) After vacuuming, fill with argon to 0.30MPa, and then fill with CO to 0.4MPa. (4) The VB growth stroke is 150mm for the crystal. (5) VB drop speed 1.0mm / h.

[0058] After the crystal is heat-treated, a test piece is cut from the crystal head and tail, and the semi-insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com