Erythritol crystal and preparation method of erythritol crystal

A technology of erythritol and crystals, which is applied in food preparation, application, food science, etc., to achieve the effect of expanding the application field, increasing the crystallization rate, and high crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

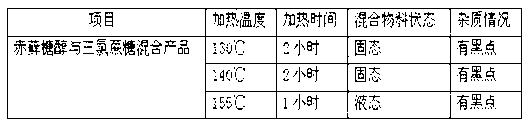

[0026] Example 1: Co-crystallization of erythritol and sucralose

[0027] Table 1 is the heating and melting data table of the mixed product of erythritol and sucralose. It can be seen from the table that when the mixed product of erythritol and sucralose is heated, the melting point of the two substances is within the range of 130-155 ° C. There are black spots of impurities. Therefore, the co-crystallization of erythritol and sucralose cannot be carried out in the form of melting, but can only be carried out in the form of liquid solution.

[0028] Table 1 Heat-thawing data table of mixed product of erythritol and sucralose

[0029]

[0030] 1. Raw material mixing

[0031] Take 200g of erythritol, dissolve it in a container with water, add 5.0g of sucralose, and stir evenly to obtain a liquid solution. The mass concentration of erythritol in the liquid solution is 70%.

[0032] 2. Co-crystal preparation and product preparation

[0033] Open the liquid solution from ...

Embodiment 2

[0035] Example 2: Co-crystallization of erythritol and sucralose

[0036] 1. Raw material mixing

[0037] Take 200g of erythritol, dissolve it in a container with water, add 2.4g of sucralose, and stir evenly to obtain a liquid solution. The mass concentration of erythritol in the liquid solution is 75%.

[0038] 2. Co-crystal preparation and product preparation

[0039] Open the liquid solution from 80°C and start stirring to cool down and crystallize, cool down to 15°C, cool down by 5-6°C per hour above 60°C, cool down by 3-4°C per hour at 60°C-45°C, cool down per hour at 45°C-10°C 6~8℃, there is no liquid water at the crystallization end point, and the co-crystal crystals are dried. The drying method can be a fluidized bed or a dryer or a box-type drying equipment, and finally sieved by a sieving machine. Granular or mixed crystal products, the crystallization yield is 100%.

Embodiment 3

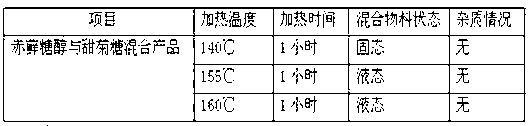

[0040] Example 3: Erythritol and stevioside co-crystallization

[0041] Table 2 is the heating and melting data table of the mixed product of erythritol and stevioside. It can be seen from the table that when the mixed product of erythritol and stevioside is heated, no black spots of impurities are generated at the melting temperature.

[0042] Table 2 Heat-thawing data table of mixed product of erythritol and stevioside

[0043]

[0044] 1. Raw material mixing

[0045] Take 200g of erythritol solid and 2.0g of stevia solid, and stir the mixture evenly.

[0046] 2. Co-crystal preparation and product preparation

[0047] Melt the mixed material at a high temperature of 155°C for 1-2 hours, then cool down to crystallize, ventilate and cool down by 15-20°C / h, and cool down to 30°C, crush the co-crystallized crystals, and then send them to a fluidized bed or dryer or box-type drying equipment to dry. Finally, the sieving process is carried out by a sieving machine, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com