Method for preparing silicon heterojunction solar cell containing composite emission layer

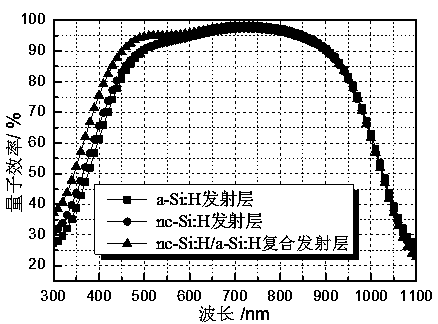

A silicon heterojunction and solar cell technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of lower battery open circuit voltage, low short-wave response of batteries, and degraded thin film microstructure, so as to reduce series resistance and parasitic Effects of absorption, reduction of interface energy band mismatch, and increase of short-wave response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

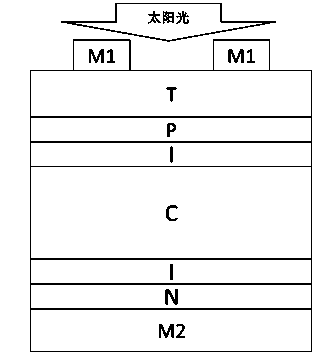

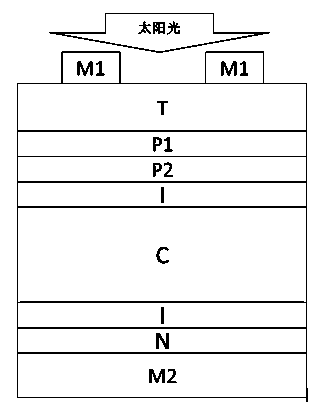

[0023] 1. Place the N-type textured Cz silicon wafer substrate in a high-vacuum plasma-enhanced chemical vapor deposition (PECVD) system, and deposit a layer of intrinsic non- Crystalline silicon I layer, and then select one side to deposit n-type amorphous silicon back field N, and then prepare to deposit p-type emitter layer on the other side.

[0024] 2. Move the sample to be processed into a 13.56MHz PECVD chamber with a background vacuum of 10 -6 Pa, the surface temperature of the sample to be processed is 180°C, and the reaction gas is introduced, and the source gas in the reaction gas is SiH 4 ; The diluent gas is H 2 ; The doping gas is TMB; the reaction gas pressure is 1.5 Torr, and the chamber electrode spacing is 20mm.

[0025] 3. Adjust the glow power density to 80mW / cm 2 , the ratio of the flow rate of various gases from [SiH 4 ]: [H 2 ]: [TMB]=1:120:1, glow deposited a 5nm a-Si:H thin film P2.

[0026] 4. Adjust the glow power density to 160mW / cm 2 , the ...

Embodiment 2

[0029] 1. Place the N-type textured Cz silicon wafer substrate in a high-vacuum plasma-enhanced chemical vapor deposition (PECVD) system, and deposit a layer of intrinsic non- Crystalline silicon I layer, and then select one side to deposit n-type amorphous silicon back field N, and then prepare to deposit p-type emitter layer on the other side.

[0030]2. Move the sample to be processed into a 13.56MHz PECVD chamber with a background vacuum of 10 -6 Pa, the surface temperature of the sample to be processed is 180°C, and the reaction gas is introduced, and the source gas in the reaction gas is SiH 4 ; The diluent gas is H 2 ; The doping gas is TMB; the reaction gas pressure is 2Torr, and the chamber electrode spacing is 20mm.

[0031] 3. Adjust the glow power density to 40mW / cm 2 , the ratio of the flow rate of various gases from [SiH 4 ]: [H 2 ]: [TMB]=1:120:2, glow deposit a 5nm a-Si:H thin film P2.

[0032] 4. Adjust the glow power density to 120mW / cm 2 , the flow r...

Embodiment 3

[0035] 1. Place the N-type textured Cz silicon wafer substrate in a high-vacuum plasma-enhanced chemical vapor deposition (PECVD) system, and deposit a layer of intrinsic non- Crystalline silicon I layer, and then select one side to deposit n-type amorphous silicon back field N, and then prepare to deposit p-type emitter layer on the other side.

[0036] 2. Move the sample to be processed into a 13.56MHz PECVD chamber with a background vacuum of 10 -6 Pa, the surface temperature of the sample to be processed is 180°C, and the reaction gas is introduced, and the source gas in the reaction gas is SiH 4 ; The diluent gas is H 2 ; The doping gas is TMB; the reaction gas pressure is 2Torr, and the chamber electrode spacing is 20mm.

[0037] 3. Adjust the glow power density to 40mW / cm 2 , the ratio of the flow rate of various gases from [SiH 4 ]: [H 2 ]: [TMB]=1:120:2.5, glow deposit a 10nm a-Si:H thin film P2.

[0038] 4. Adjust the glow power density to 120mW / cm 2 , the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com