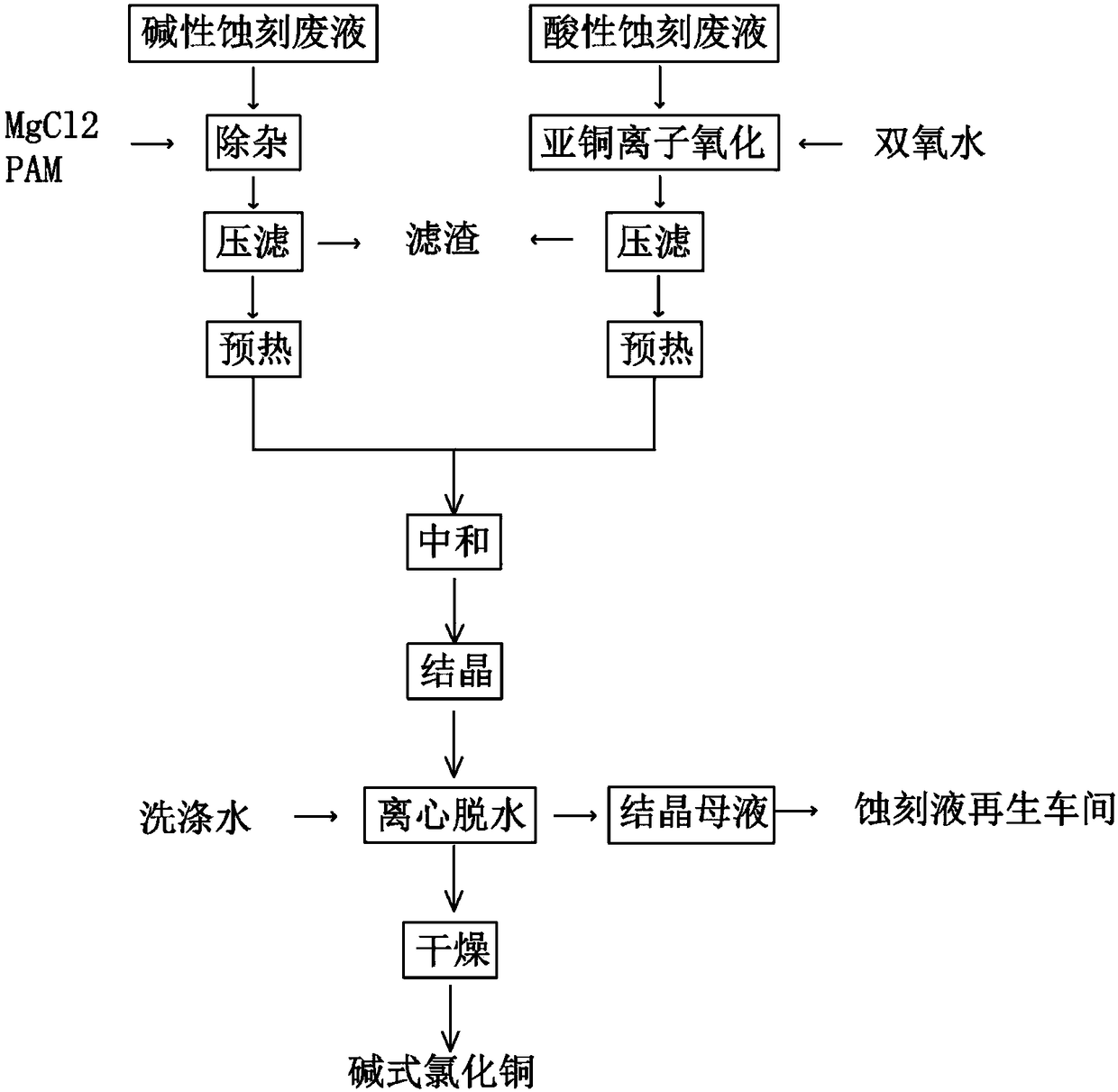

Comprehensive recycling process of copper-containing etching waste solution

A technology of etching waste liquid and acidic etching waste liquid, which is applied in the direction of copper sulfate, copper halide, copper chloride, etc., can solve the problems of complex process, waste of etching waste liquid, and expensive use, so as to simplify the treatment process and improve copper recovery rate, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Acidic etching waste liquid 500L, which contains 150g / L copper ion, 1.0mol / L hydrochloric acid, 4000mg / L COD, a small amount of cuprous ion, pH is 3.5. 500L alkaline etching waste liquid, which contains 130g / L copper ion, 10mol / L ammonium ion, 3800mg / L COD and 15ppm arsenic, pH is 8.9.

[0040] The specific treatment process is as follows:

[0041] (1) Pretreatment of alkaline etching waste liquid, add medicament 820g magnesium chloride, 120gPAM to remove impurity arsenic in alkaline etching waste liquid, remove mechanical particle impurity through filter press;

[0042] (2) Pretreatment of acidic etching waste liquid, adding hydrogen peroxide to the acidic etching waste liquid to oxidize cuprous ions to copper ions, T improves the recovery rate, and removes mechanical particulate matter and oil stains through a filter press, so as not to affect the crystallization of subsequent products;

[0043] (3) Pump the pretreated acidic etching waste liquid and alkaline etching...

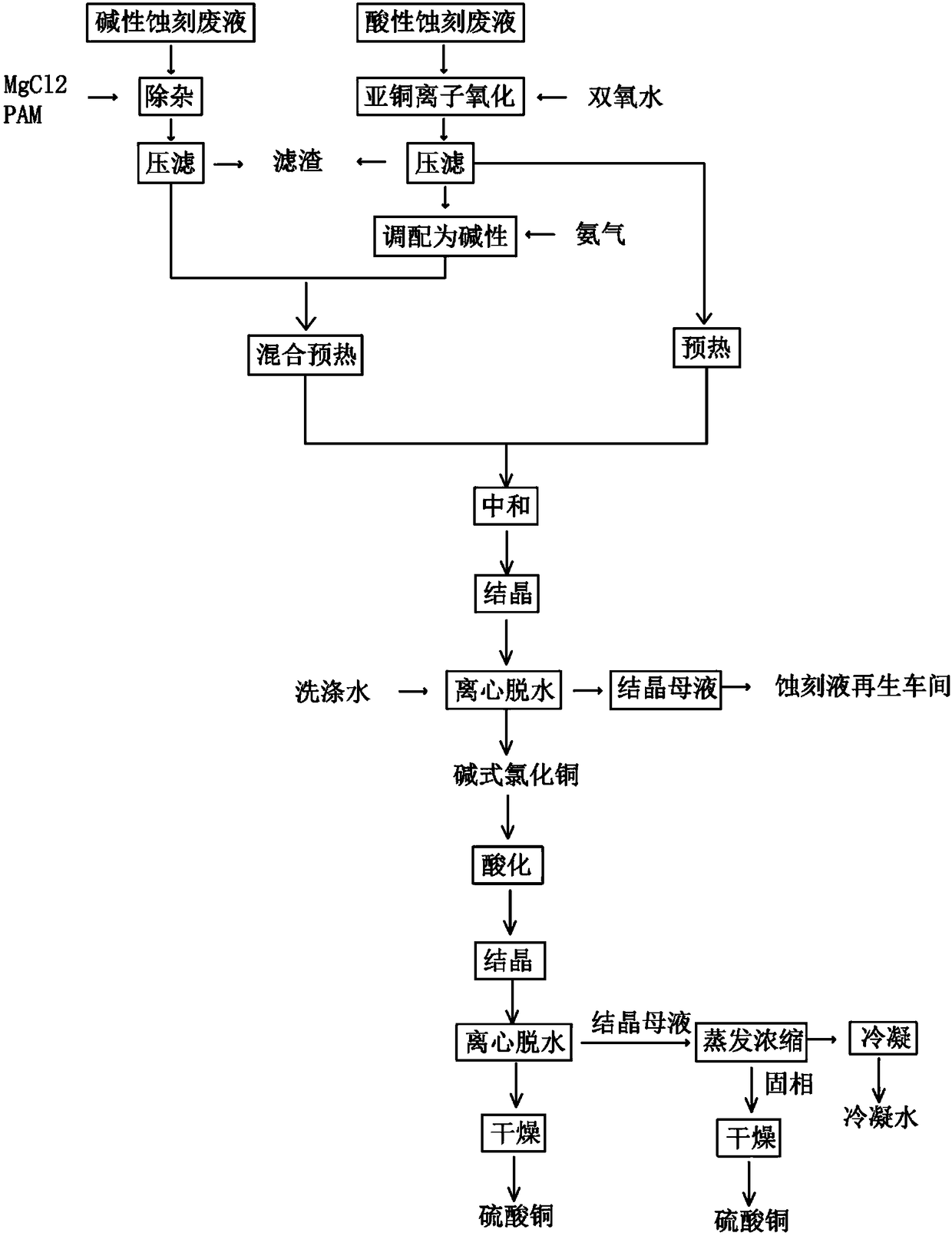

Embodiment 2

[0048] Acidic etching waste liquid 1000L, which contains 140g / L copper ion, 2.0mol / L hydrochloric acid, 4000mg / L COD, a small amount of cuprous ion, pH is 2.5. 100L of alkaline etching waste liquid, which contains 130g / L of copper ions, 10mol / L of ammonium ions, 3800mg / L of COD and 15ppm of arsenic, with a pH of 8.9.

[0049] The specific treatment process is as follows:

[0050] Pretreatment of acidic etching waste liquid, adding hydrogen peroxide to the acidic etching waste liquid to oxidize cuprous ions to copper ions, and remove mechanical particulate matter and oil stains through a filter press;

[0051] Pump 450L of pretreated acidic etching waste liquid into about 5500mol of ammonia gas, prepare it into an alkaline solution with a pH of 8.5, and keep stirring gently to fully react;

[0052] The main reaction equation:

[0053] HCl+NH 3 =NH4 Cl

[0054] CuCl 2 +4NH 3 ==Cu(NH 3 ) 4 Cl 2 ;

[0055] Mix 450L of prepared alkaline etching solution with 100L of etchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com