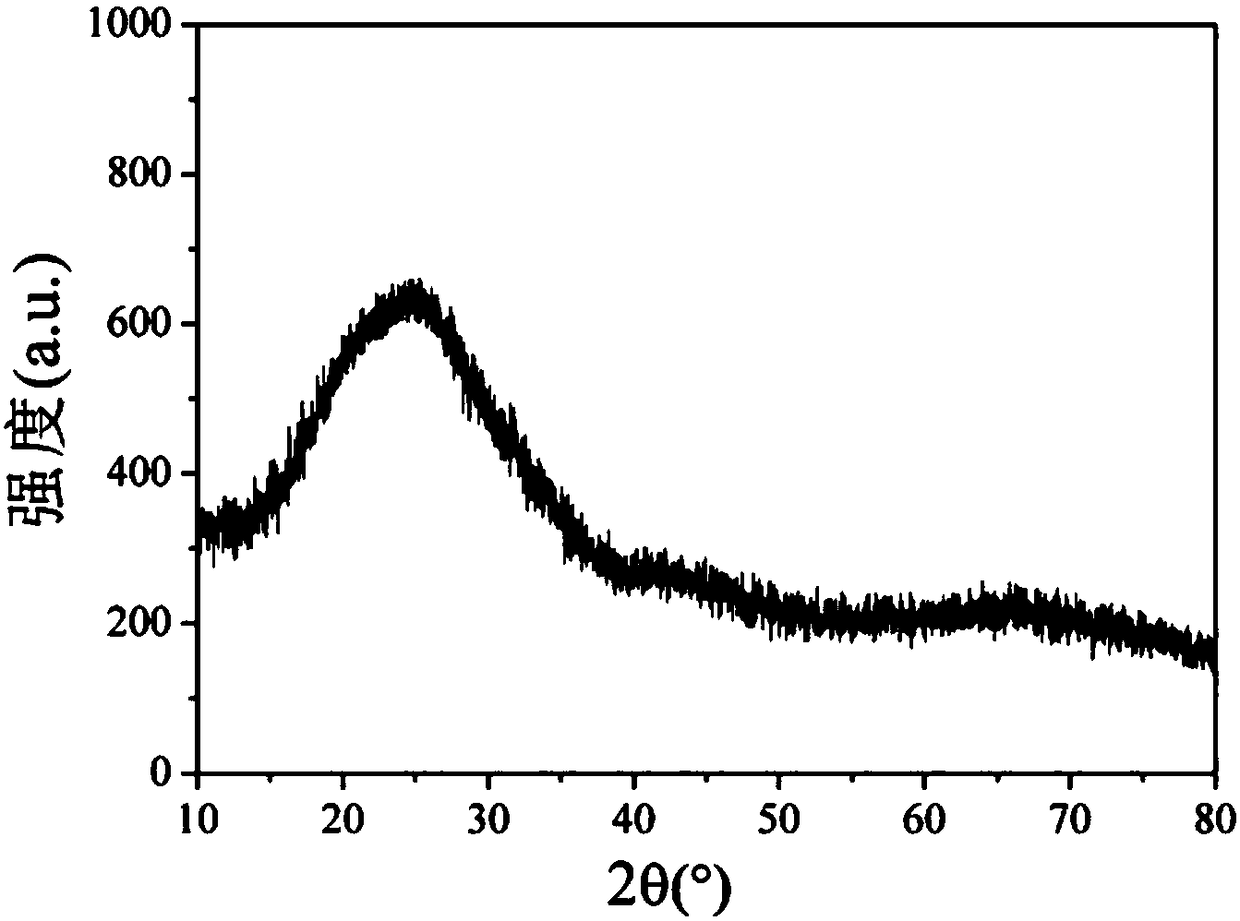

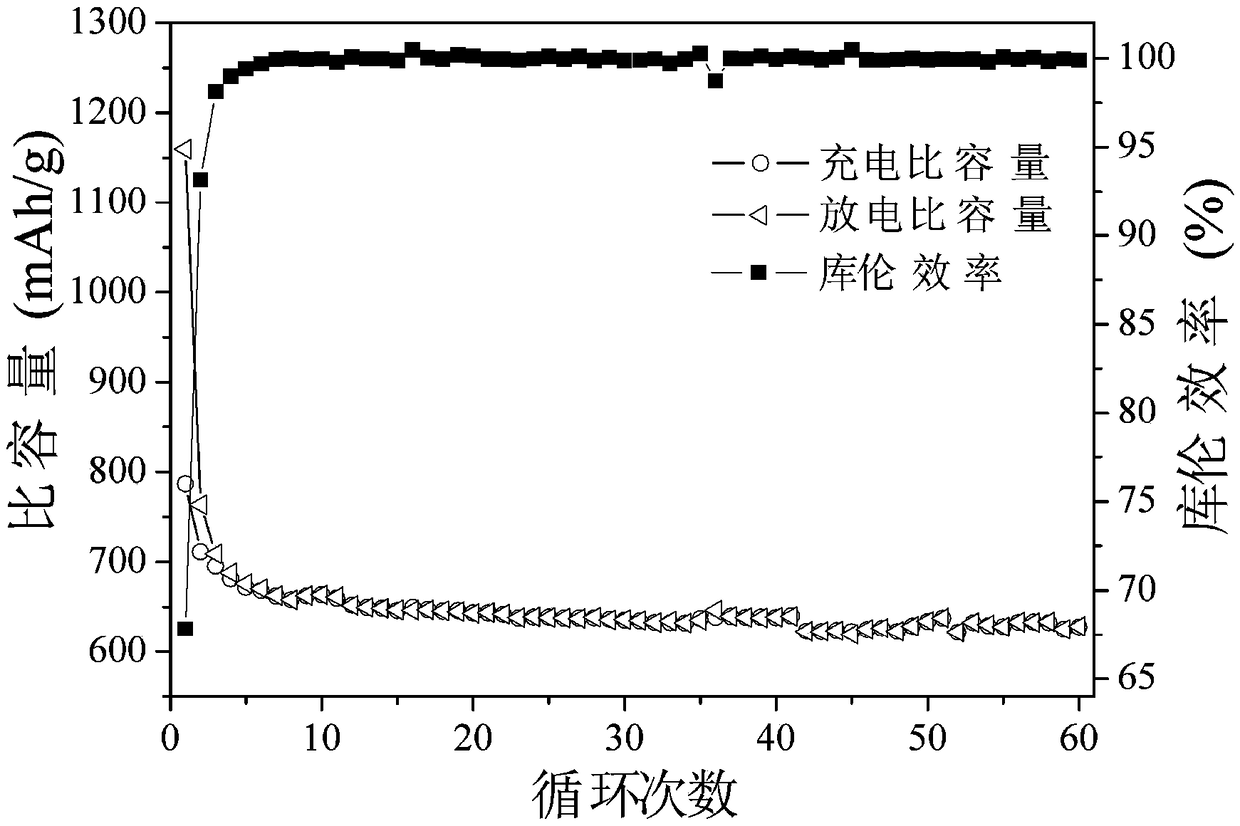

Carbon-rich porous SiOC negative-electrode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of buffering volume changes, stabilizing the amorphous structure, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

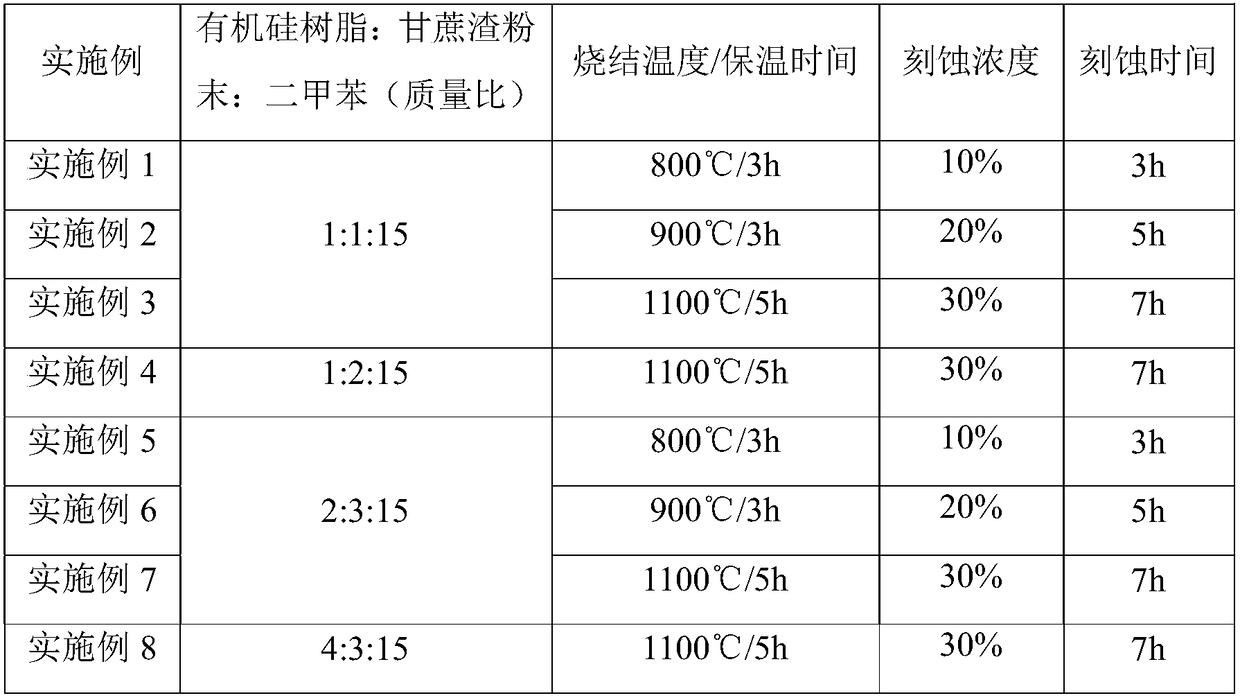

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0029] A carbon-rich porous SiOC negative electrode material for a lithium ion battery and a preparation method thereof, comprising the steps of:

[0030] S01: After the biomass waste is crushed and screened, it is ball milled. The ball milling time is 24 hours, the speed of the ball mill is 250r / min, and then it is taken out and dried; the treated biomass waste is screened and the particle size is less than 64 μm to obtain biomass. waste powder. Biomass waste can be selected from bagasse or corn straw or wheat straw or rice straw. In the embodiment, bagasse is selected as an example.

[0031] S02: Mix silicone resin and bagasse powder, and add an organic solution as a solvent, wherein the organic solution is used to dissolve the silicone resin; the organic solution can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com