High-entropy alloy double technology preparation method

A high-entropy alloy and duplex process technology, applied in the field of high-entropy alloy, can solve the problems of uneven composition and structure of alloy, difficulty of high-entropy alloy, low purity, etc., achieve dense and uniform structure, solve ratio problems, adjust The effect of many parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention provides a high-entropy alloy dual-process preparation method. The method comprises the following steps:

[0024] (1) According to the composition, content and physical and chemical properties of the high-entropy alloy elements to be prepared, decompose and design the types of the four welding wires and the composition, content, existence form and location of the welding wire elements, and then prepare the welding wires;

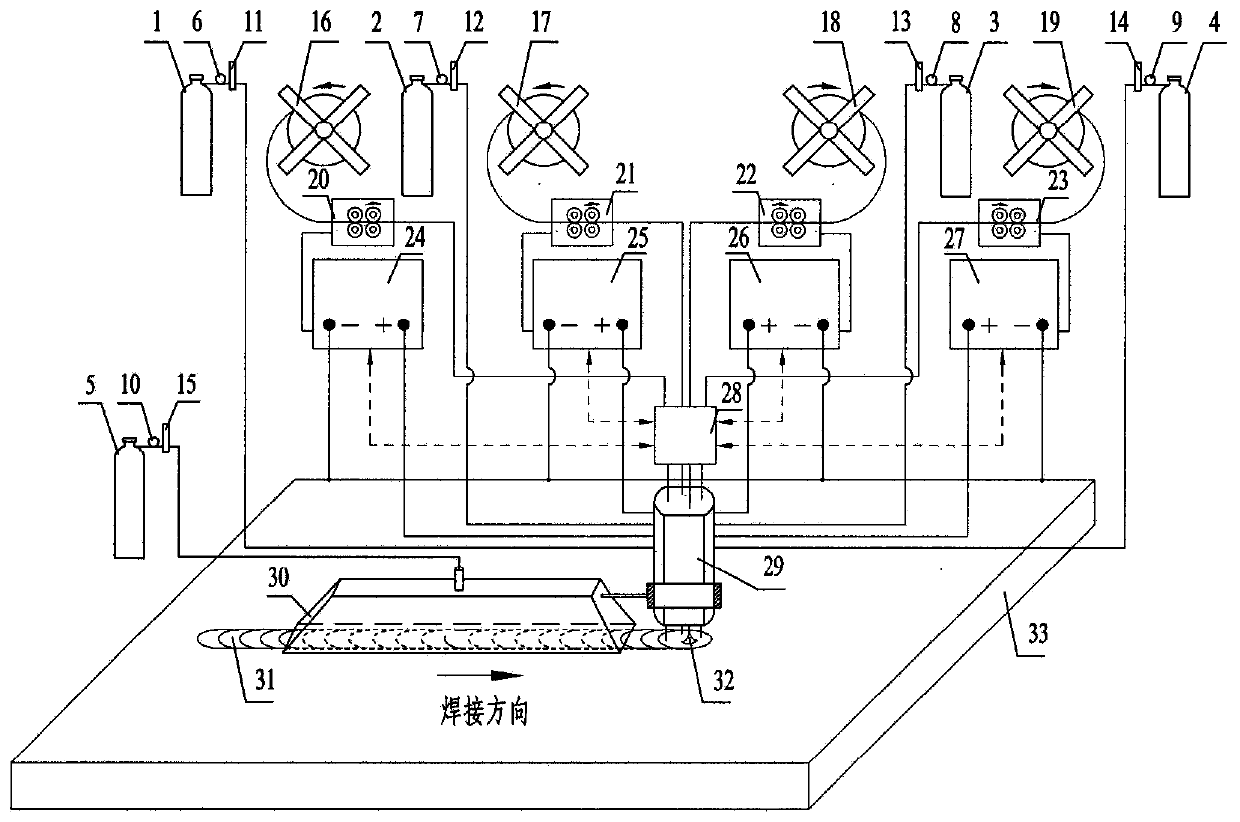

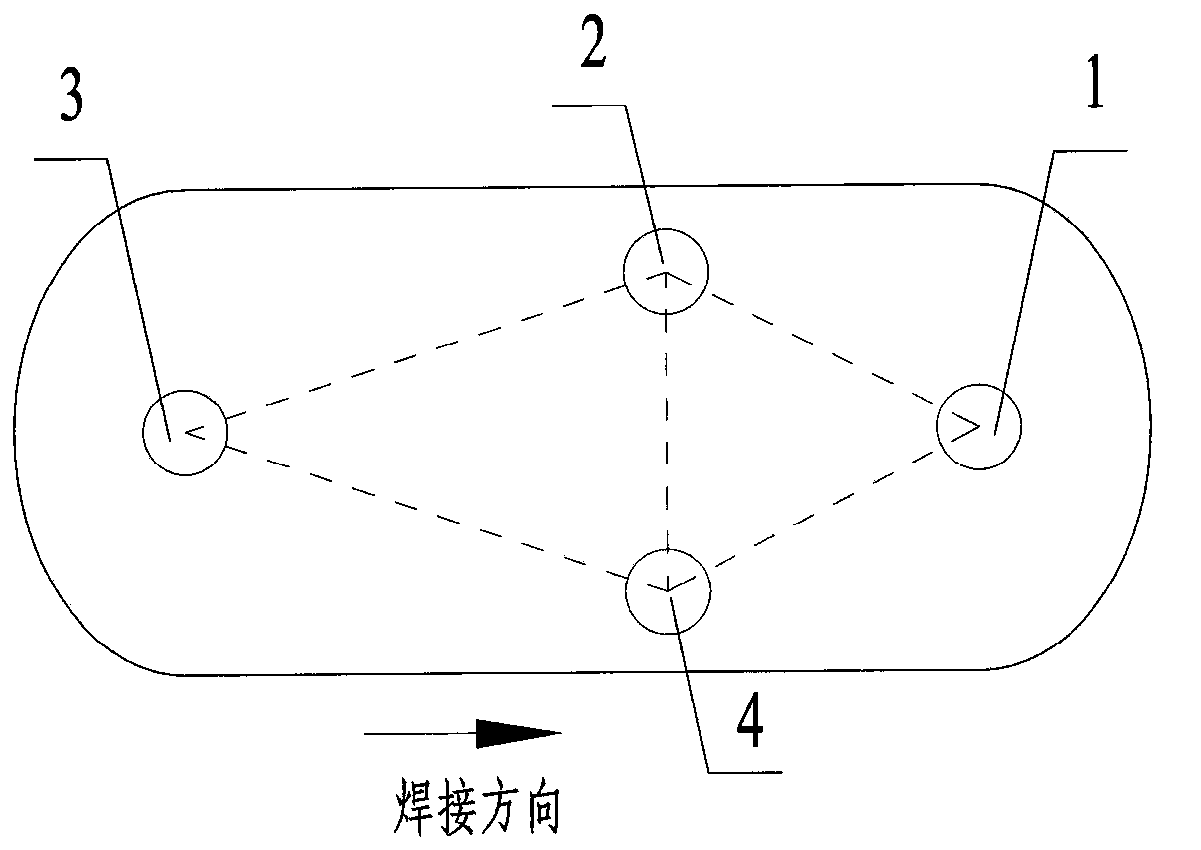

[0025] (2) Arrange 4 welding wires including 1 leading welding wire, 2 following welding wires and 1 trailing welding wire in an integrated manner, the axis extension lines of the 4 welding wires and the 4 contact points of the workpiece form a harmonious quadrilateral, and the axis of the leading welding wire extends The contact points between the wire and the workpiece are respectively equal to the distance between the two axis extension lines following the welding wire and the contact points of the workpiece,...

Embodiment 1

[0045] A high entropy alloy Al 17 co13 Cr 20 Fe 13 Ni 22 V 5.5 C 1.4 Mg 1.5 mn 1.5 Mo 1.4 Ti 1 W 2.3 Nb 0.4 , the preparation method comprises the following steps:

[0046] (1) Decompose and design the types of four welding wires and the composition and content of welding wire elements according to the composition, content and physical and chemical properties of the high-entropy alloy elements to be prepared, as shown in Table 1. Among them, the high-melting point alloy elements exist in the form of alloys, and the low The location where the melting point alloy elements exist is the solid welding wire, and the diameters of the solid welding wire 1, the solid welding wire 2, the solid welding wire 3 and the solid welding wire 4 are all 0.8mm, and then the welding wires are prepared.

[0047] Table 1 Type of welding wire, element composition and content (wt%)

[0048] Numbering Al Ni Cr Fe co Mo W Ti Nb mn Mg V C Solid wire 1 92 ...

Embodiment 2

[0054] A high-entropy alloy Co 8.5 Cr 17 Cu 21 Fe 12 Mo 6.6 Ni 26 B 1.4 sn 1.2 Ti 1.6 V 0.9 W 0.6 Y 1.1 Zn 1 Al 0.3 mn 0.4 Ta 0.4 , the preparation method comprises the following steps:

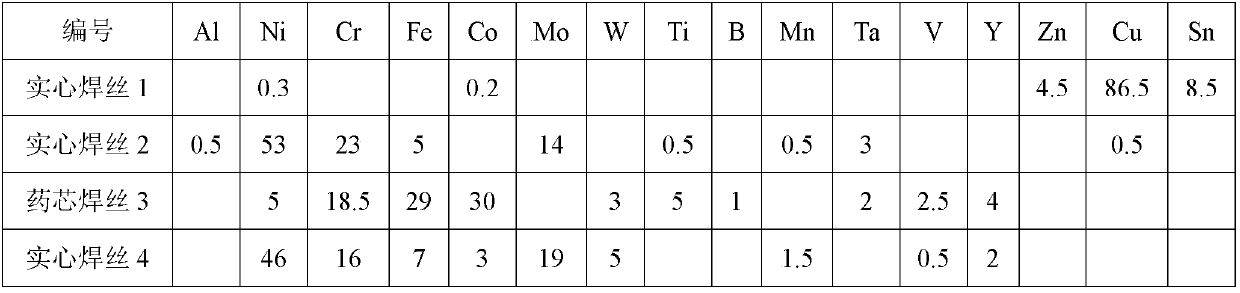

[0055] (1) Decompose and design the types of four welding wires and the composition and content of welding wire elements according to the composition, content and physical and chemical properties of the high-entropy alloy elements to be prepared, as shown in Table 3. Among them, the high melting point alloy elements exist in the form of alloys, and the low The location where the melting point alloy elements exist is the solid welding wire, and the diameters of the solid welding wire 1, the solid welding wire 2, the flux-cored welding wire 3 and the solid welding wire 4 are all 1.0 mm, and then the welding wires are prepared.

[0056] Table 3 Types of welding wire, element composition and content (wt%)

[0057]

[0058] (2) Welding parameters are set, welding shielding gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com