Nanometer red long-afterglow luminescent material and preparation method thereof

A long-lasting luminescence and red technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve wide application prospects, improve regularity, and reduce the effect of preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

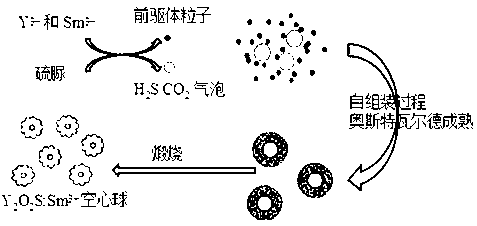

Method used

Image

Examples

Embodiment 1

[0031] (1) According to the molar ratio of yttrium nitrate: samarium nitrate: thiourea: PVP: ethylene glycol = 2: 0.01: 6: 0.05: 40, measure 40 mL of yttrium nitrate solution (0.5mol / L), samarium nitrate solution (0.05 mol / L) 2mL, ethylene glycol 250mL, weigh 4.57g of thiourea, 20g of PVP, put them in a container and stir to dissolve, form a transparent solution, and keep it sealed at 120°C for 8 hours to obtain a brown product.

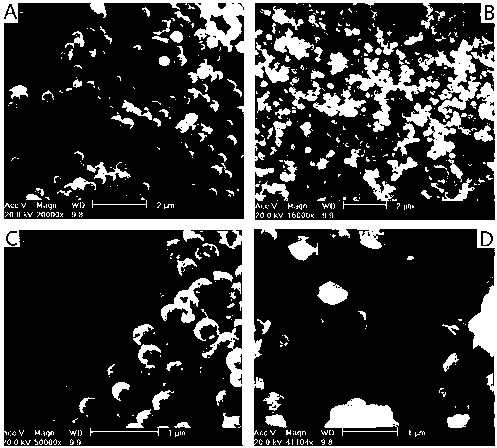

[0032] (2) Centrifuge the cooled tan product, filter and wash with deionized water for 3 times, then filter and wash with ethanol for 2 times, and dry at 60°C for 12 hours to obtain the following: figure 2 The curve a in image 3 A. Figure 4 Prebody shown in a.

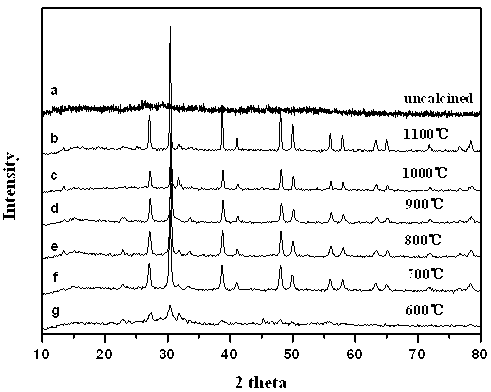

[0033] (3) Anneal the precursor in a reducing atmosphere at 700°C for 2 hours. Wherein, the reducing atmosphere is formed by placing the graphite crucible with the precursor in a closed corundum crucible covered with 5g of reduced C powder and 3g of sulfur powder. figure 2 The curve f...

Embodiment 2

[0036] (1) According to the molar ratio of yttrium chloride: samarium chloride: thiourea: PVP: ethylene glycol = 2: 0.03: 7: 0.08: 50, measure 40 mL of yttrium chloride solution (0.5mol / L), and chlorinate Samarium solution (0.05mol / L) 6mL, ethylene glycol 300mL, weigh 5.33g of thiourea and 32g of PVP, put them in a container and stir to dissolve, form a transparent solution, keep it sealed at 140°C for 10 hours to obtain a brown color product.

[0037] (2) Centrifuge the cooled tan product, filter and wash with deionized water for 3 times and then with ethanol for 2 times, and dry at 60°C for 12 hours to obtain the precursor.

[0038] (3) Anneal the precursor in a reducing atmosphere at 800°C for 3 hours. Wherein, the reducing atmosphere is formed by placing the graphite crucible with the precursor in a closed corundum crucible covered with 5g of reduced C powder and 3g of sulfur powder. figure 2 The red nano long afterglow luminescent material shown in the curve e.

[003...

Embodiment 3

[0041] (1) According to the molar ratio of yttrium acetate: samarium acetate: thiourea: PVP: ethylene glycol = 2: 0.05: 8: 0.1: 60, measure 40 mL of yttrium acetate solution (0.5 mol / L), samarium acetate solution (0.05 mol / L) 10mL, ethylene glycol 350mL, weighed 6.09g of thiourea, 40g of PVP, placed in a container and stirred to dissolve, formed a transparent solution, and kept it sealed at 160°C for 12 hours to obtain a brown product.

[0042] (2) Centrifuge the cooled tan product, filter and wash with deionized water for 3 times and then with ethanol for 2 times, and dry at 70°C for 10 hours to obtain the precursor.

[0043] (3) Anneal the precursor in a reducing atmosphere at 900°C for 2 hours. Wherein, the reducing atmosphere is formed by placing the graphite crucible with the precursor in a closed corundum crucible covered with 5g of reduced C powder and 3g of sulfur powder. figure 2 The curve d in image 3 The red nano long afterglow luminescent material shown in C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com