Method for manufacturing La-contained high-performance neodymium iron boron rare earth permanent magnet

A rare earth permanent magnet and manufacturing method technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of shortage of rare earths, rising prices of rare earths, shortage of heavy rare earth elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

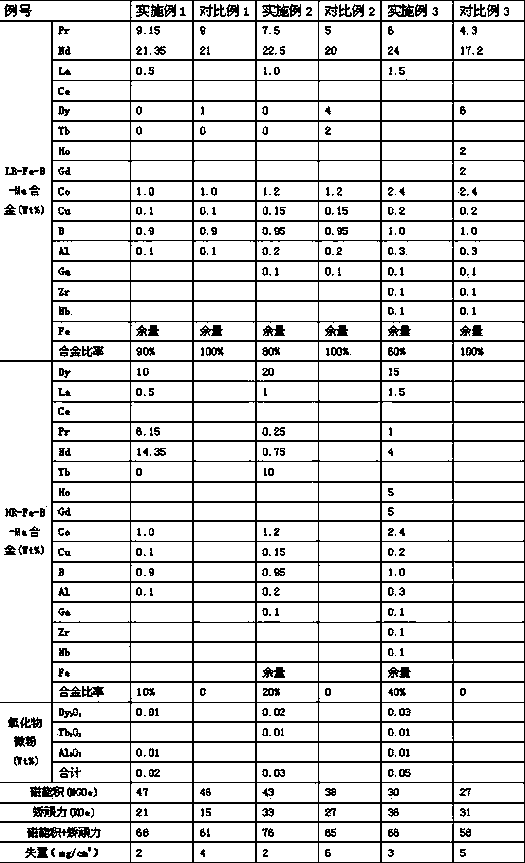

Embodiment 1

[0059] Select La-LR-Fe-B-Ma alloy and La-HR-Fe-B-Mb alloy 600Kg smelting respectively according to Table 1 Example 1 composition, and in the molten state, the alloy is cast onto a water-cooled rotating copper roll for cooling Alloy flakes are formed. During the smelting process, the cooling rate of La-LR-Fe-B-Ma alloy and La-HR-Fe-B-Mb alloy is adjusted by adjusting the rotating speed of the rotating copper roller to obtain La-LR-Fe-B- The average grain size of Ma alloy is 2.8 μm; the average grain size of La-HR-Fe-B-Mb alloy is 1.8 μm; La-LR-Fe-B-Ma alloy and La -HR-Fe-B-Mb alloy flakes are subjected to hydrogen crushing, and the alloy flakes after hydrogen crushing and the metal oxides listed in Table 1 are put into the mixer according to the ratio of Table 1, and mixed under nitrogen protection. The time is 60 minutes. After the mixing, airflow milling is carried out. The powder collected by the cyclone collector and the ultrafine powder collected by the filter are put into...

Embodiment 2

[0066] Select La-LR-Fe-B-Ma alloy and La-HR-Fe-B-Mb alloy 600Kg smelting respectively by the composition in the embodiment 2 of table 1, alloy is poured to the rotating copper roll of band water cooling under molten state The upper cooling forms alloy flakes. During the smelting process, the cooling rate of La-LR-Fe-B-Ma alloy and La-HR-Fe-B-Mb alloy is adjusted by adjusting the rotation speed of the rotating copper roller to obtain La-LR-Fe- The average grain size of the B-Ma alloy is 2.3 μm; the average grain size of the La-HR-Fe-B-Mb alloy is 1.3 μm; the La-LR-Fe-B-Ma alloy is selected according to the ratio listed in Table 1 Carry out hydrogen crushing with La-HR-Fe-B-Mb alloy sheet, the alloy sheet after hydrogen crushing and the metal oxide listed in Table 1 are put into the mixer together by the ratio of Table 1, and mix under nitrogen protection, The mixing time is 40 minutes. After the mixing, airflow milling is carried out. The powder collected by the cyclone collect...

Embodiment 3

[0072] Select La-LR-Fe-B-Ma alloy and La-HR-Fe-B-Mb alloy 600Kg smelting respectively by the composition in the embodiment 3 of table 1, alloy is poured to the rotary copper roll of band water cooling under molten state The upper cooling forms alloy flakes. During the smelting process, the cooling rate of La-LR-Fe-B-Ma alloy and La-HR-Fe-B-Mb alloy is adjusted by adjusting the rotation speed of the rotating copper roller to obtain La-LR-Fe- The average grain size of B-Ma alloy is 2.8-3.2μm; the average grain size of La-HR-Fe-B-Mb alloy is 2.1-2.4μm; select La-LR-Fe- The B-Ma alloy and La-HR-Fe-B-Mb alloy flakes are subjected to hydrogen crushing, and the alloy flakes after hydrogen crushing are put into the mixer together with the metal oxides listed in Table 1 according to the ratio of Table 1, and are protected under nitrogen protection. Down-mixing, the mixing time is 90 minutes, airflow milling is carried out after mixing, the powder collected by the cyclone collector and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com