Motor and manufacturing method thereof

A manufacturing method and magnetic steel technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of permanent magnet motor magnet demagnetization, affecting motor performance and life, without Set anti-demagnetization structure and other issues to achieve the effect of improved anti-demagnetization ability, long life and improved anti-demagnetization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

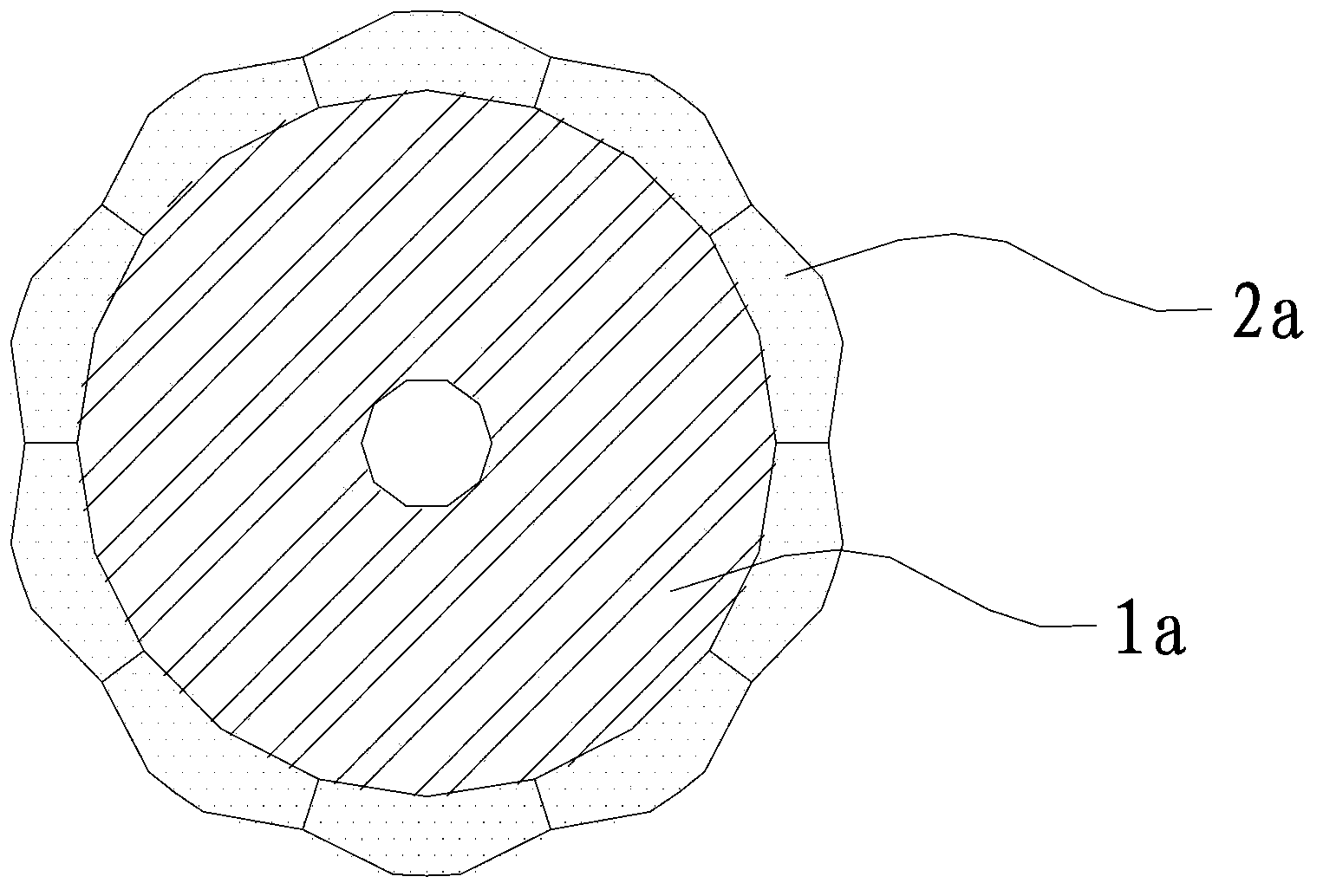

[0041] Different from the slot in the motor provided in Embodiment 1, in this embodiment, as shown in FIG. 3( a ) and FIG. 3( b ), the end of the magnetic steel 2 extends into the slot 101 . The width of the slot 101' on the rotor core 1' of the rotor 10' can be greater than the gap between the adjacent magnets 2', and the opening of the slot 101' has a larger width, so that the slot 101' extends to the gap between the magnets 2'. The bottom part further weakens the strength of the magnetic field formed by the armature reaction at the corners at both ends of the magnetic steel 2', and more effectively avoids demagnetization of the magnetic steel 2'.

Embodiment 3

[0043] Different from the shape of the non-magnetic insulator in the motor provided in Embodiments 1 and 2, in this embodiment, such as Figure 4 As shown, the slot on the rotor core 1'' of the rotor 10'' is provided with a non-magnetic insulator 3'', and both sides of the upper end of the non-magnetic insulator 3'' are provided with buckles on the magnetic steel 2' The raised portion 31'' at the upper end, the cross-section of the non-magnetic insulator 3'' is roughly in the shape of a "T", which is beneficial to improve the structural reliability of the magnetic steel 2''. In specific applications, the shape of the non-magnetic insulator 3'' can be set according to actual conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com