Method for preparing high-coercivity, high-toughness and high-corrosion-resistance sintered Nd-Fe-B permanent magnet

A high coercivity, NdFeB technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as material fracture and corrosion, achieve simple operation, save rare earth resources, and be easy to industrialize production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

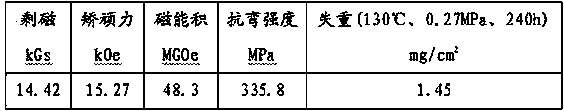

Embodiment 1

[0021] The design is based on the NdFeB-based alloy composition Nd11.8Fe82.2B6 (atomic percentage) of the 2:14:1 phase, according to the composition of the design, and considering the burning loss of rare earth Nd 3% (weight percentage), using the scale ingot casting process Prepare NdFeB-based quick-setting flakes with a thickness of about 300 μm, and prepare 2:14:1 NdFeB-based powders with an average particle size of 3.5 μm by hydrogen breaking and jet milling, and add a weight fraction of 4%, an average particle size of Pure Cu nano-powder with a diameter of 40 nm. Mix the two powders uniformly in a mixer. The uniformly mixed powder is oriented and pressed in a 2.0T magnetic field and isostatically pressed. The obtained compact is placed in a vacuum In the sintering furnace, sinter at 1050°C for 2 hours, and finally carry out secondary heat treatment, that is, heat treatment at 750°C (primary heat treatment temperature) and 350°C (secondary heat treatment temperature) for 2 ...

Embodiment 2

[0024] The design is based on the NdFeB-based alloy composition Nd11.8Fe82.2B6 (atomic percentage) of the 2:14:1 phase, according to the composition of the design, and considering the burning loss of rare earth Nd 3% (weight percentage), using the scale ingot casting process Prepare NdFeB-based quick-setting flakes with a thickness of about 300 μm, and prepare 2:14:1 NdFeB-based powders with an average particle size of 3.5 μm by hydrogen breaking and jet milling, and add 3% by weight, average particle size Pure Cu nano-powder with a diameter of 60 nm, mix the two powders uniformly in a mixer, and the uniformly mixed powder is oriented and pressed in a 2.0T magnetic field and isostatically pressed, and the obtained compact is placed in a vacuum In the sintering furnace, sinter at 1050°C for 2 hours, and finally carry out secondary heat treatment, that is, heat treatment at 750°C (primary heat treatment temperature) and 350°C (secondary heat treatment temperature) for 2 hours res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com