Patents

Literature

113 results about "Flat detector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

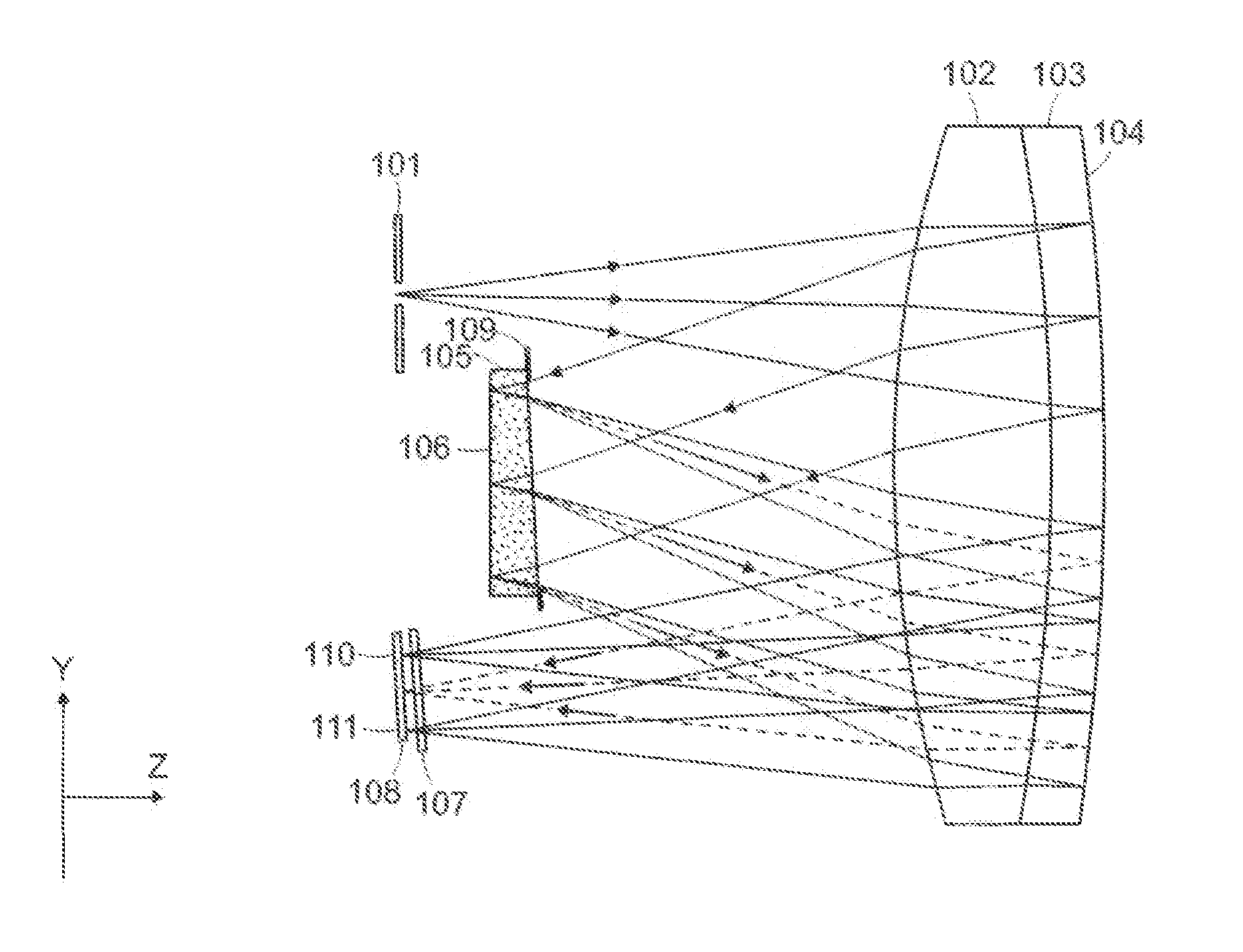

Gridless time-of-flight mass spectrometer for orthogonal ion injection

InactiveUS20010011703A1Reduce voltageFacilitates taskMaterial analysis using wave/particle radiationTime-of-flight spectrometersFlight directionFlat detector

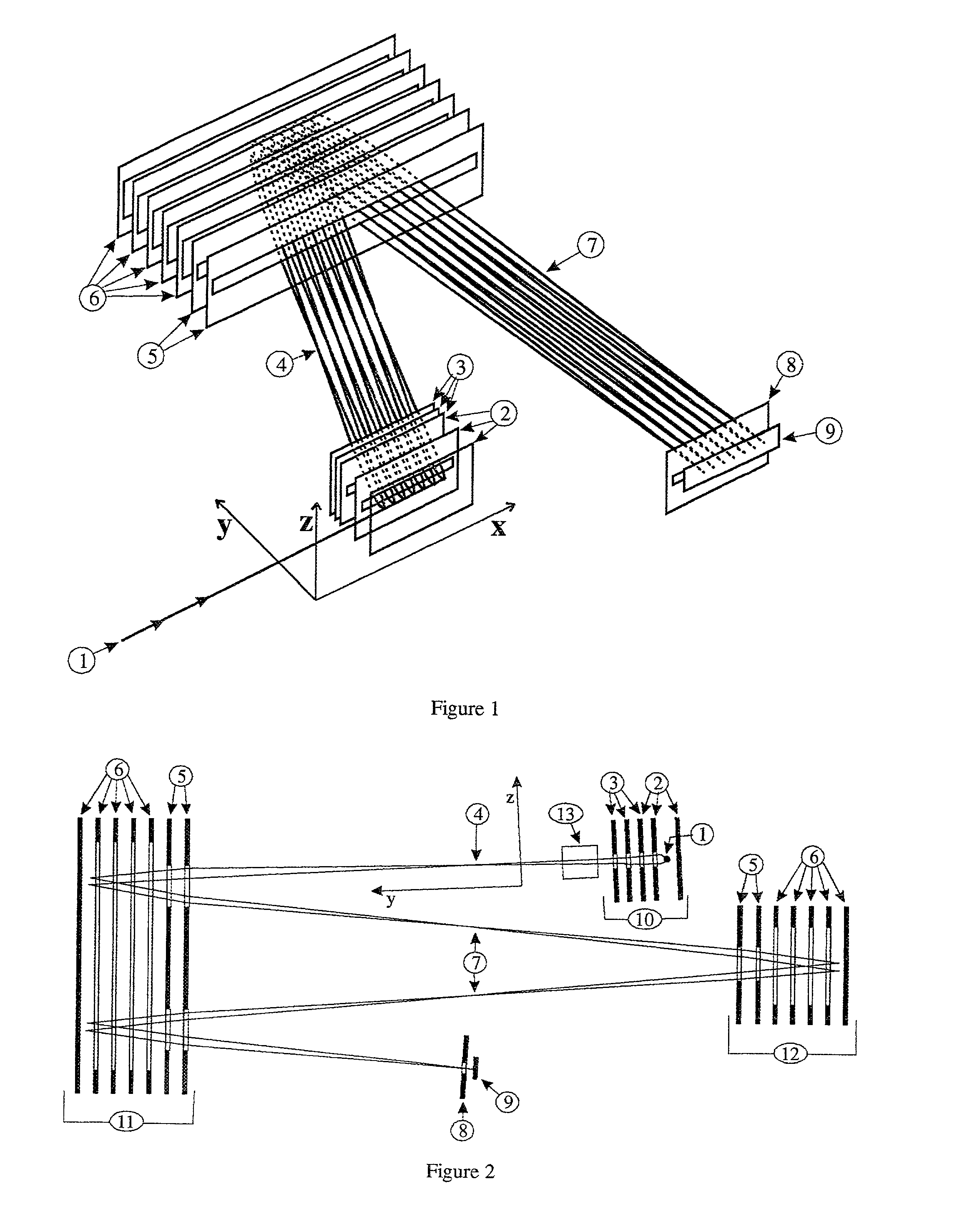

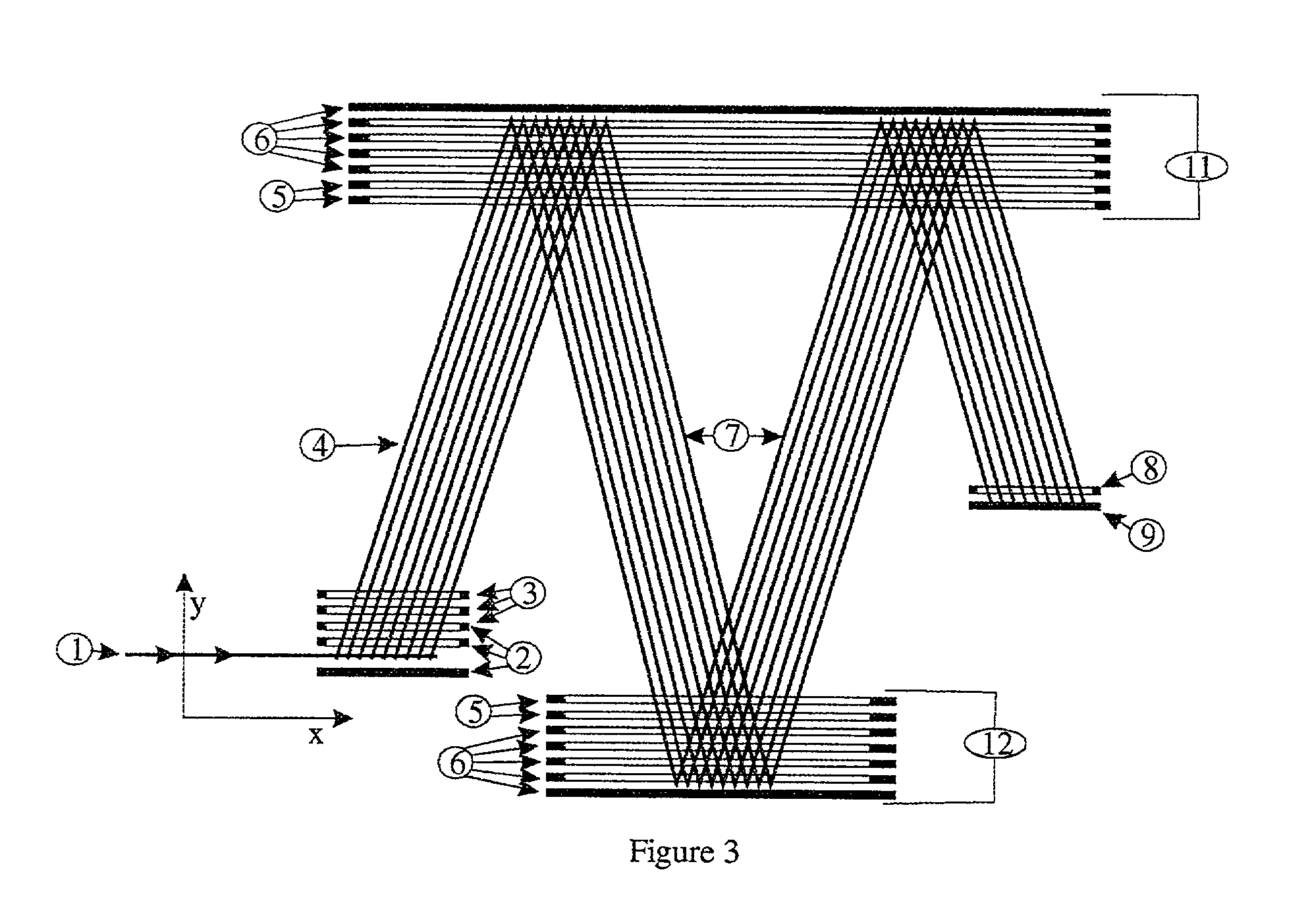

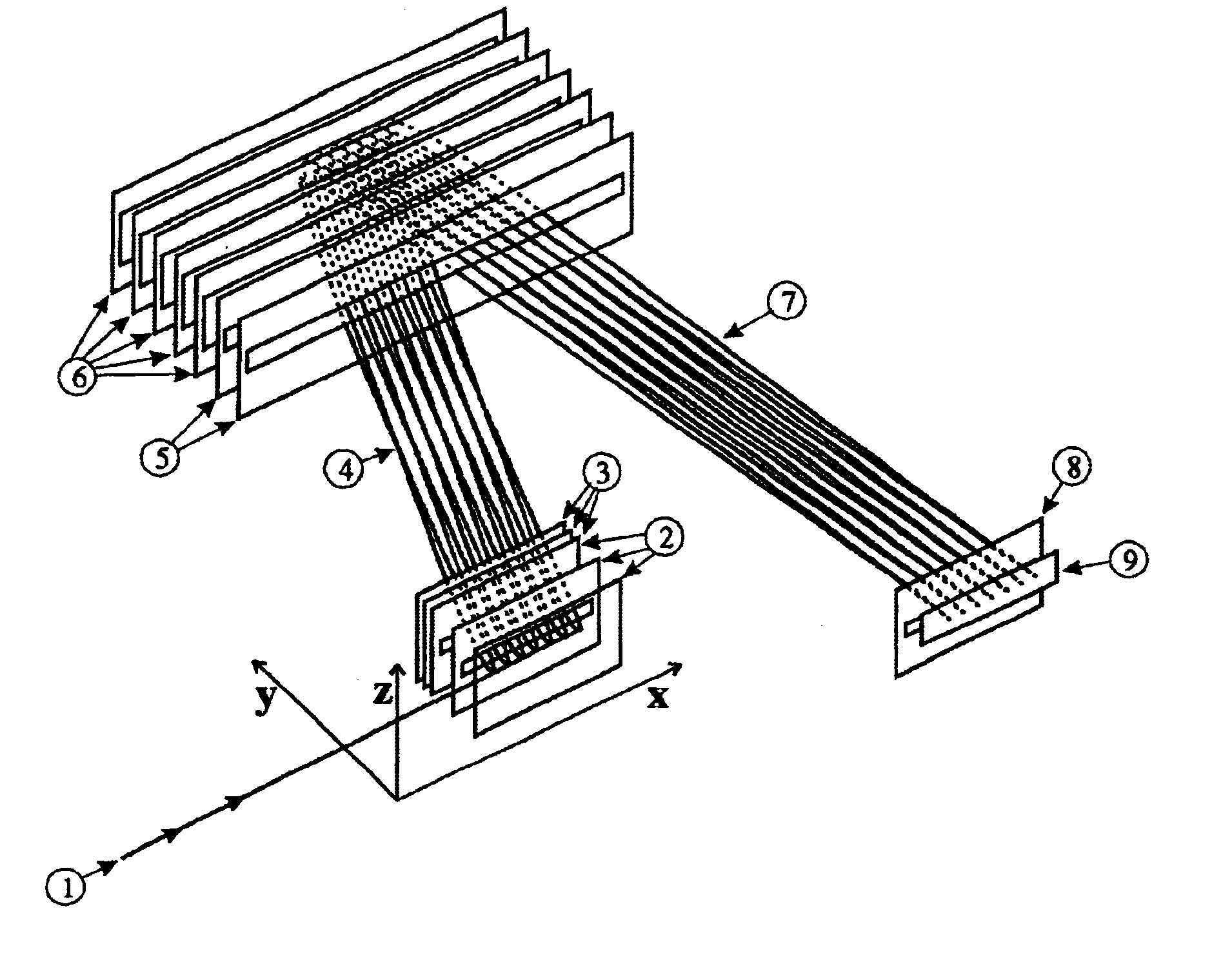

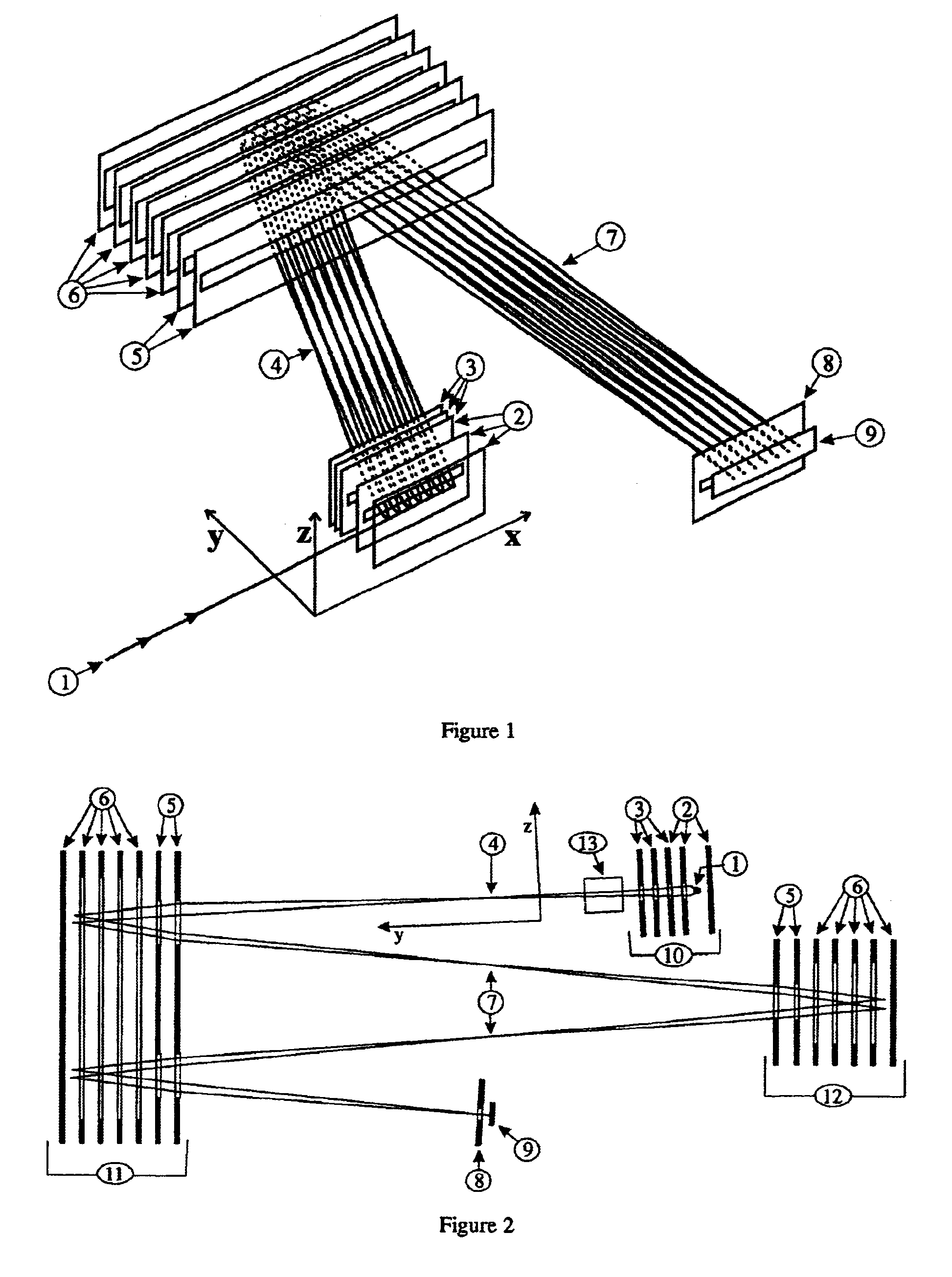

The invention relates to a time-of-flight mass spectrometer for injection of the ions orthogonally to the time-resolving axis-of-flight component, with a pulser for acceleration of the ions of the beam in the axis-of-flight direction, preferredly with a velocity-focusing reflector for reflecting the ion beam and with a flat detector at the end of the flight section. The invention consists of using, both for acceleration in the pulser and for reflection in the reflectors, a gridless optical system made up of slit diaphragms which can spatially focus the ions onto the detector in the direction vertical to the directions of injection and flight axis, but which does not have any focusing or deflecting effect on the other directions. For some reflector geometries it is essential to use an additional cylindrical lens for focusing, and for other reflector geometries the use of such a lens may be advantageous.

Owner:BRUKER DALTONIK GMBH & CO KG

Gridless time-of-flight mass spectrometer for orthogonal ion injection

InactiveUS6717132B2Shorten the effective lengthEasy to adjustMaterial analysis using wave/particle radiationTime-of-flight spectrometersFlight directionFlat detector

The invention relates to a time-of-flight mass spectrometer for injection of the ions orthogonally to the time-resolving axis-of-flight component, with a pulser for acceleration of the ions of the beam in the axis-of-flight direction, preferably with a velocity-focusing reflector for reflecting the ion beam and with a flat detector at the end of the flight section. The invention consists of using, both for acceleration in the pulser and for reflection in the reflectors, a gridless optical system made up of slit diaphragms which can spatially focus the ions onto the detector in the direction vertical to the directions of injection and flight axis, but which does not have any focusing or deflecting effect on the other directions. For some reflector geometries it is essential to use an additional cylindrical lens for focusing, and for other reflector geometries the use of such a lens may be advantageous.

Owner:BRUKER DALTONIK GMBH & CO KG

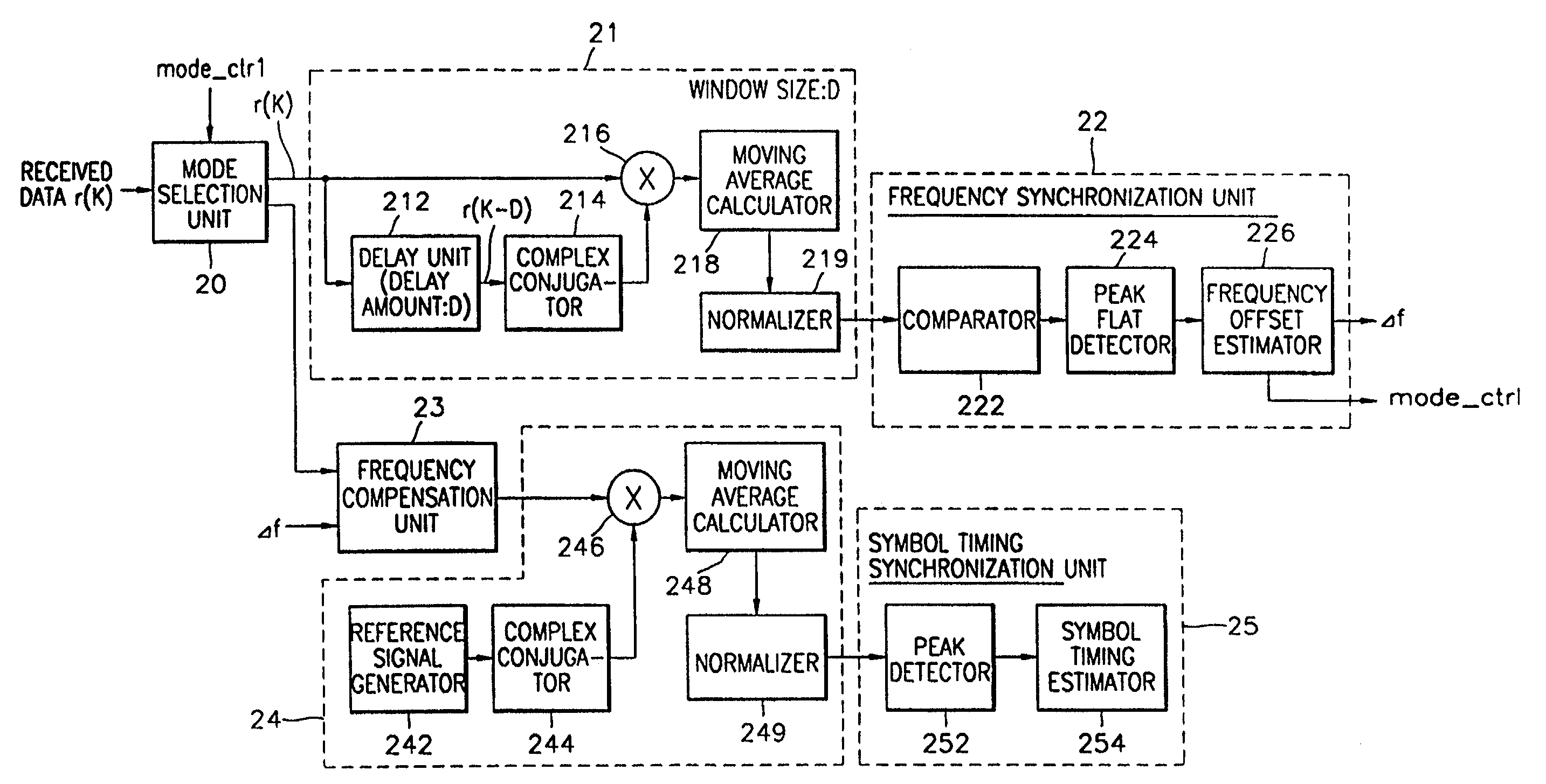

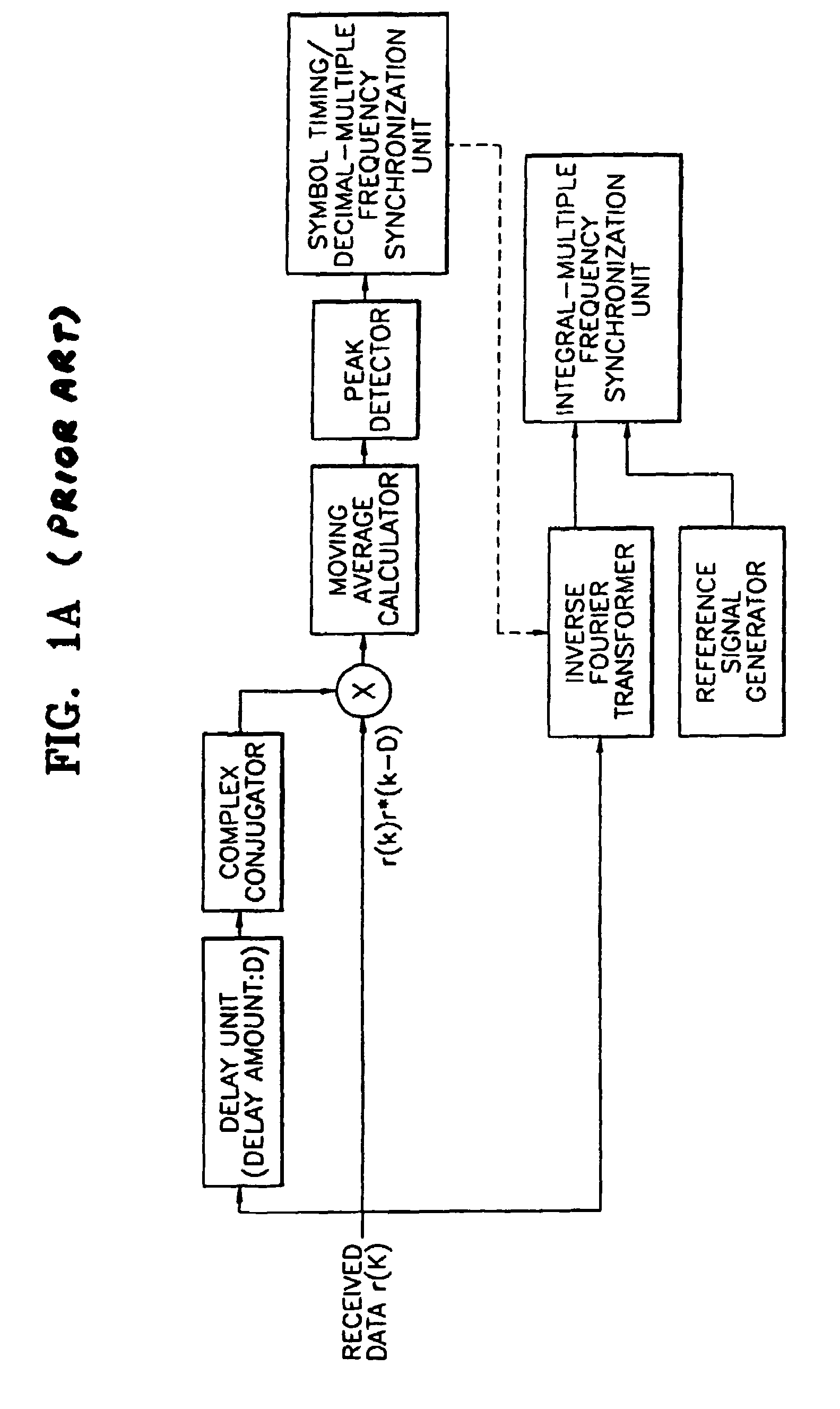

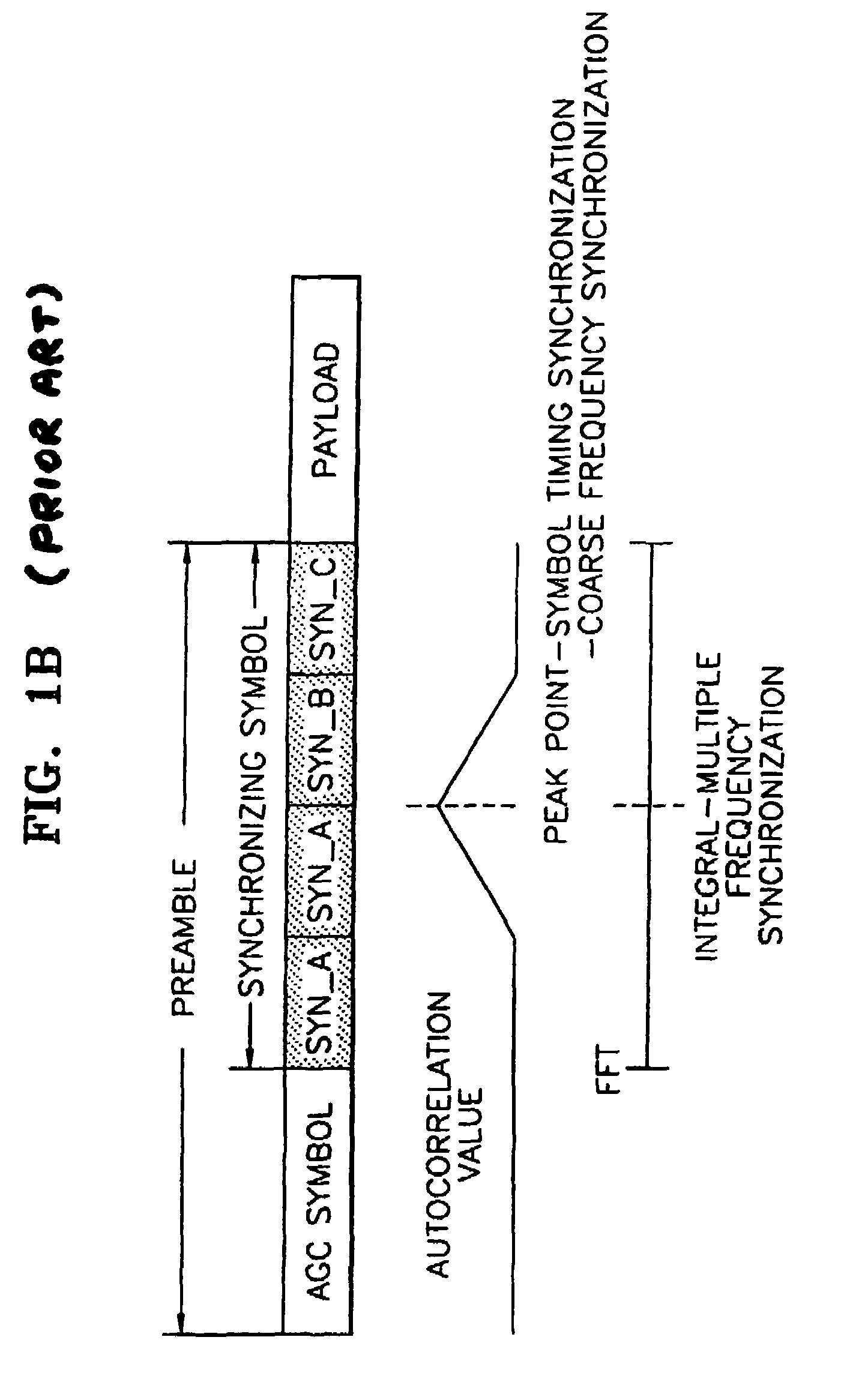

Apparatus and method for achieving symbol timing and frequency synchronization to orthogonal frequency division multiplexing signal

InactiveUS7058151B1Accurate frequency synchronizationAccurate symbol timingCarrier regulationTime-division multiplexFlat detectorPeak value

A frequency and symbol timing synchronization apparatus for orthogonal frequency division multiplexed (OFDM) signals, and a method performed by the apparatus are provided. This apparatus includes an autocorrelation unit, a comparator, a peak flat detector, a frequency offset estimator, a frequency offset compensation unit, a cross correlation unit and a symbol timing synchronization unit. The autocorrelation unit receives data including a synchronizing symbol made up of at least three identical synchronizing signals, delays the received data by a predetermined delay amount, performs autocorrelation between the received data and the delayed data, normalizes an autocorrelated value, and outputs a normalized autocorrelated value. The comparator compares the normalized autocorrelated value with a predetermined threshold value. The peak flat detector detects as a flat section a section where the normalized autocorrelated value is equal to or greater than the threshold value. The frequency offset estimator estimates a frequency offset within the flat section to obtain a frequency offset value. The frequency offset compensation unit compensates for the frequency offset of a received signal using the frequency offset value. The cross correlation unit performs cross correlation using a frequency offset-compensated signal and a reference signal, and normalizes the cross-correlated value to output a normalized cross-correlated value. The symbol timing synchronization unit detects a point where the cross-correlated value is maximum, and performs symbol timing estimation, thereby performing symbol timing synchronization. In the symbol timing and frequency synchronization apparatus and method, accurate frequency synchronization can be achieved because a large sample error can be allowed. Also, a symbol timing error can be reduced since symbol timing synchronization is achieved using a frequency offset-compensated signal.

Owner:SAMSUNG ELECTRONICS CO LTD

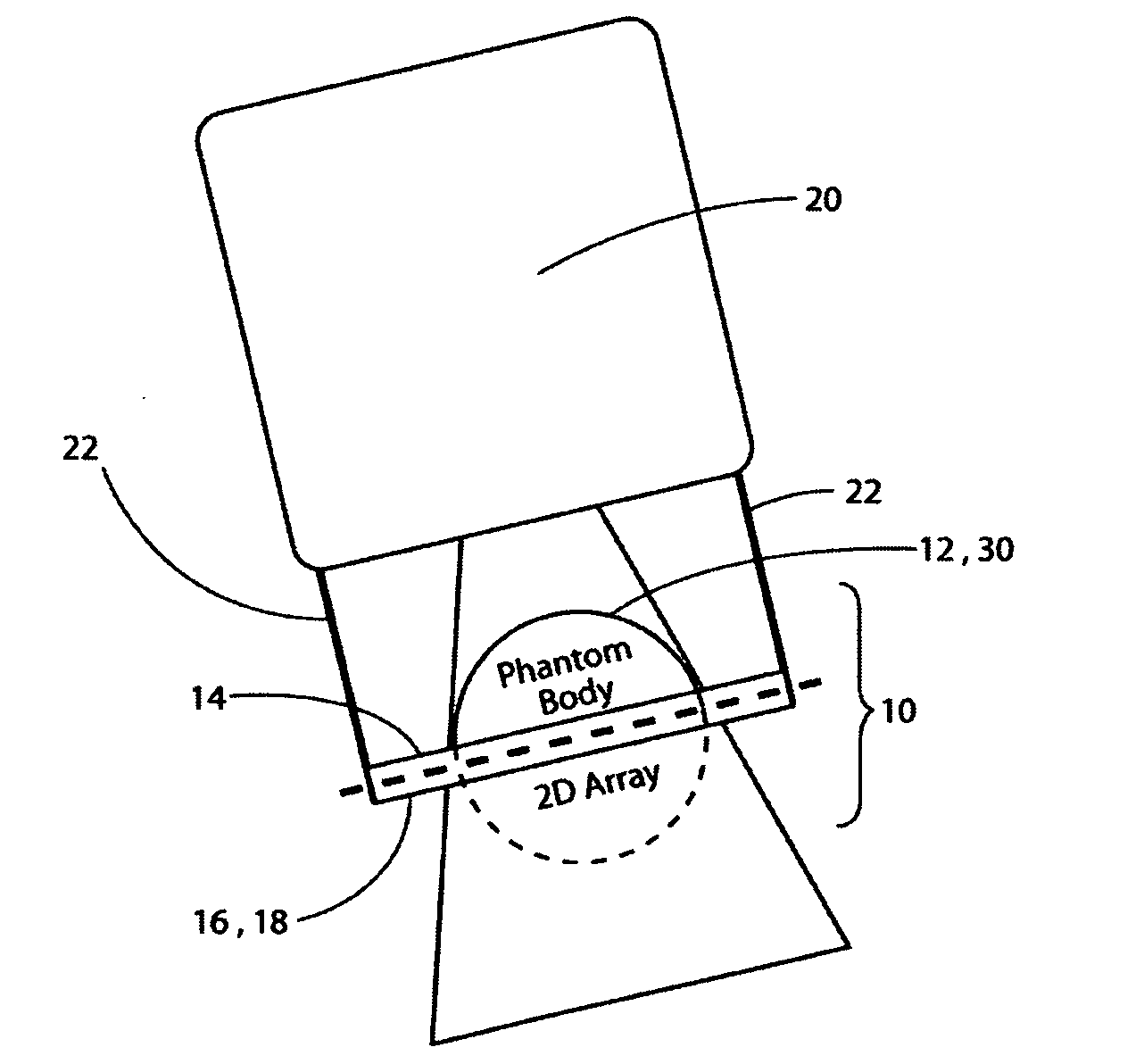

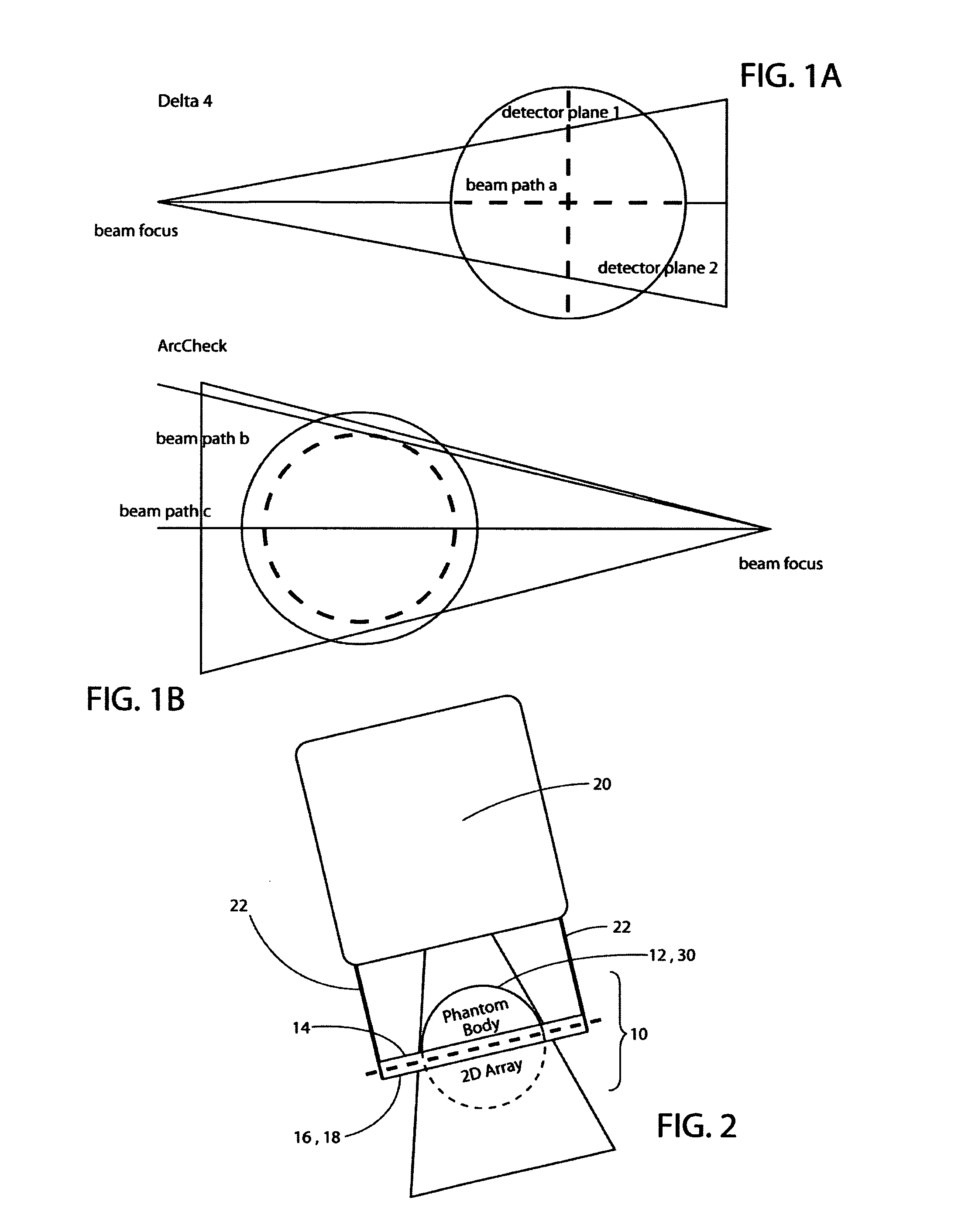

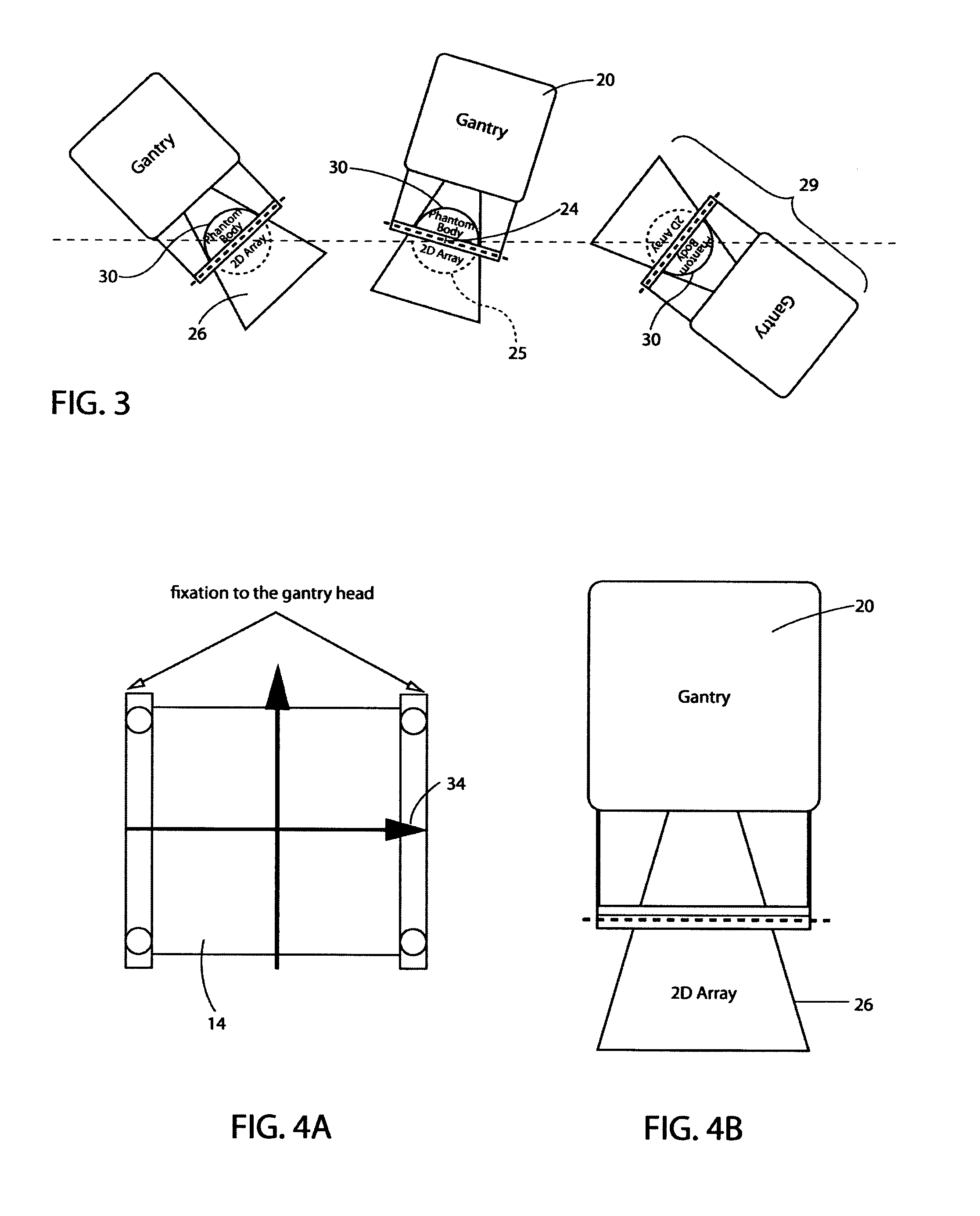

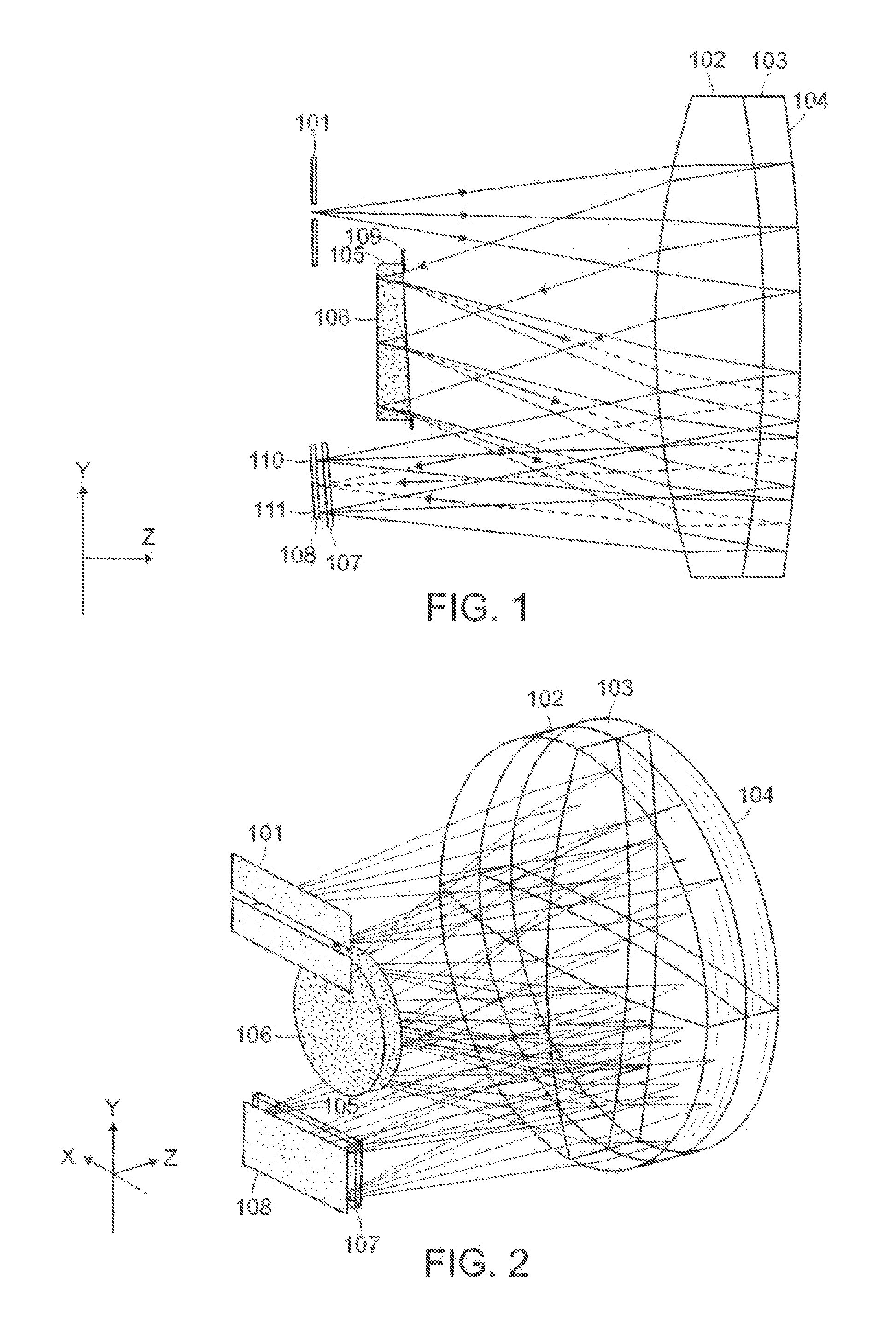

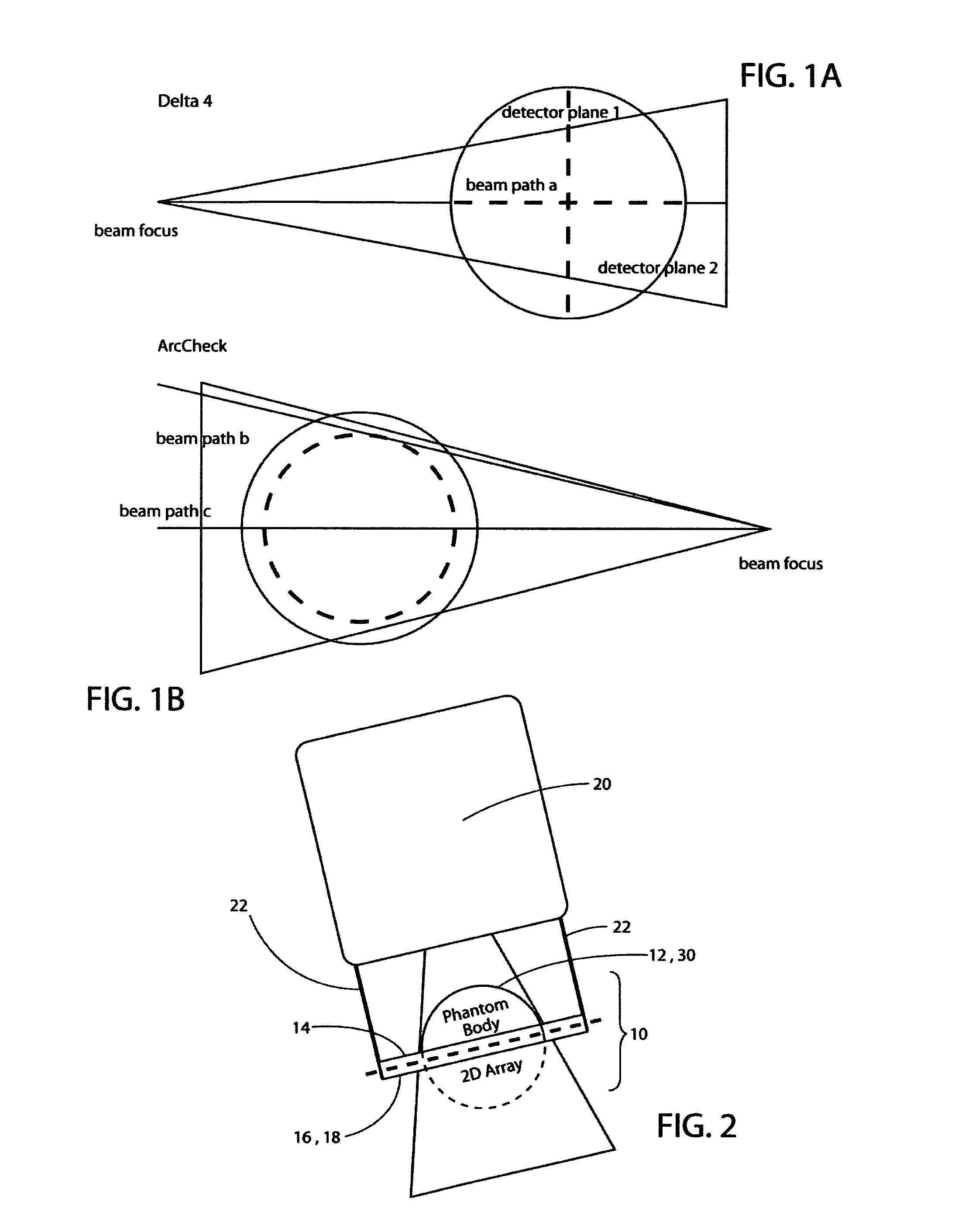

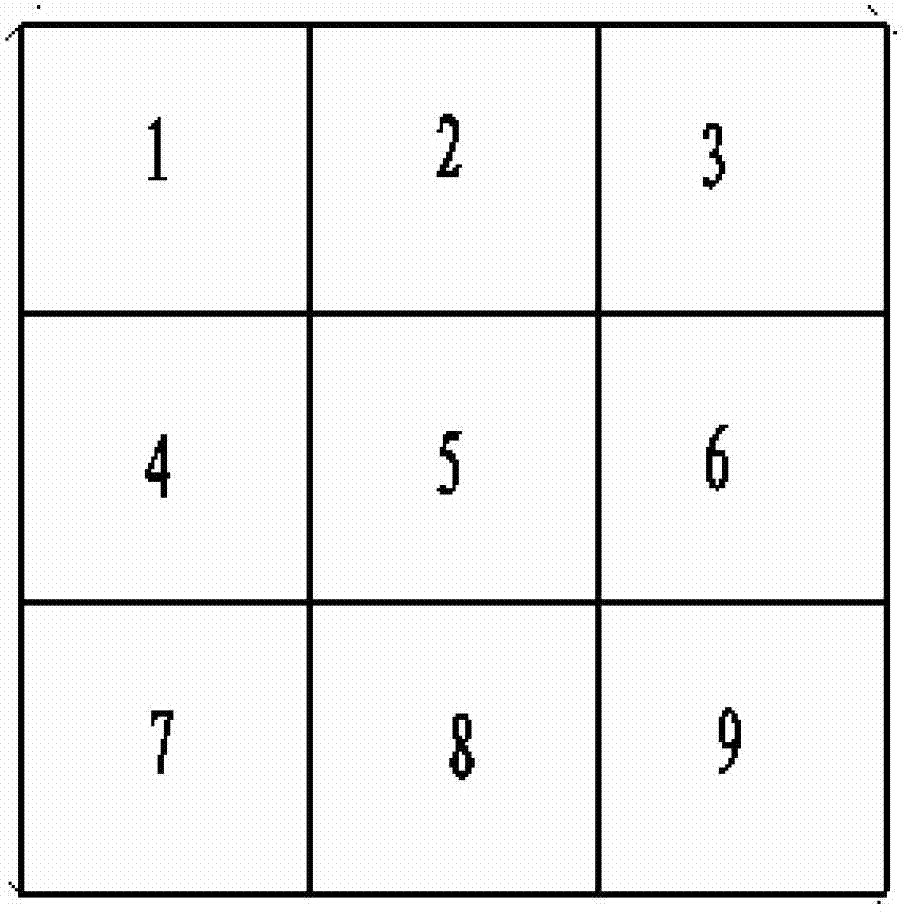

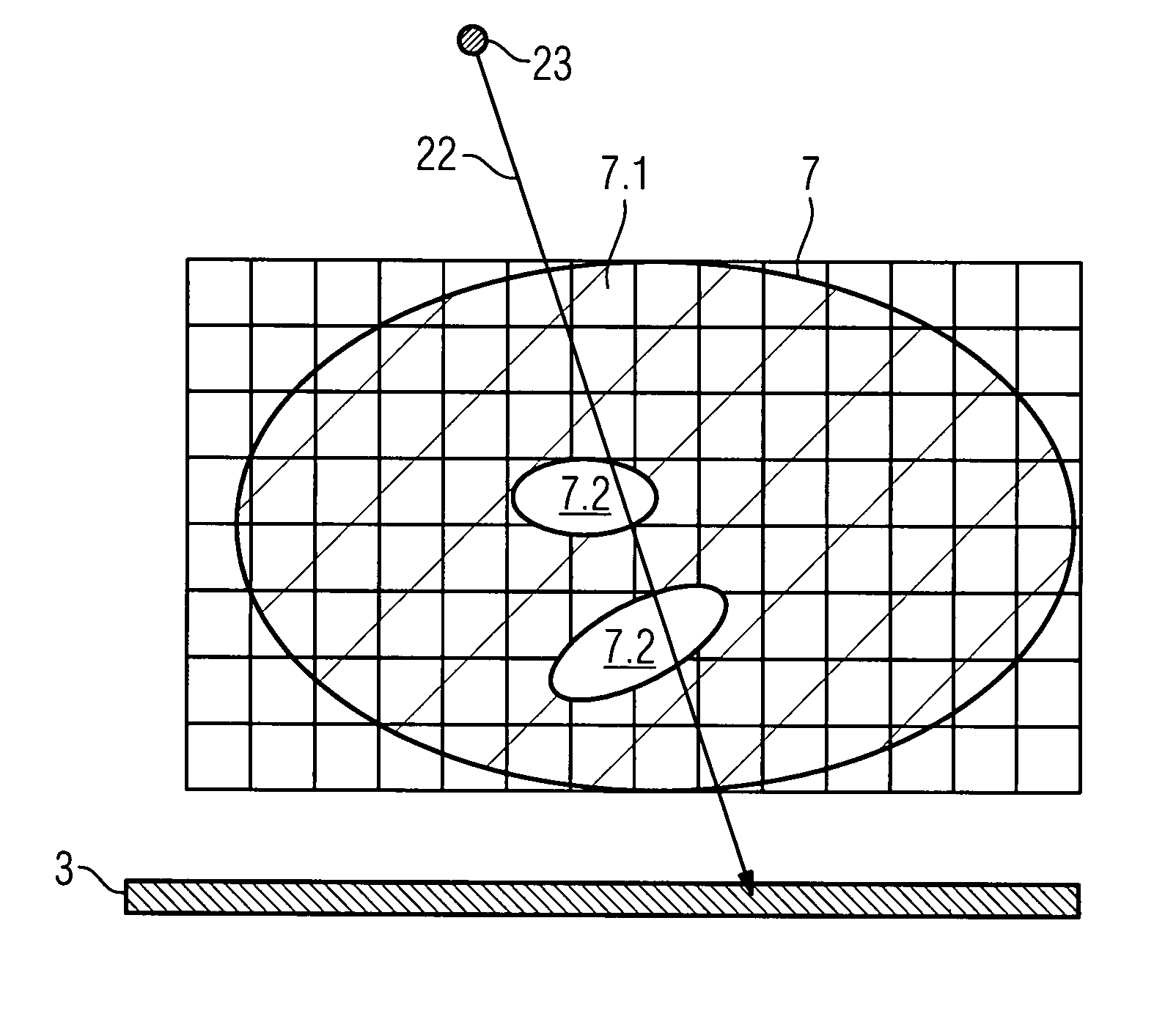

Rotationally symmetrical coherent verification phantom (virtual patient) with a flat detector disposed on a rotary axis integrated in a multi purpose qc-accessory

InactiveUS20120305793A1Without loss of accuracyMaterial analysis by optical meansPhotometry using electric radiation detectorsRotational axisTwo dimensional detector

A quality control accessory (QC accessory) is provided which is adapted for use in linear accelerator quality control or in verification of an arbitrary isocentric radiation treatment plan of a patient or radiation sensitive body. The accessory includes an absorber, a detector and an optional orientation device. The absorber is rotationally symmetric, preferably spherical or hemispherical. The detector is adapted to be fixed in a stationary spatial relationship with respect to the absorber. The optional orientation device is adapted to maintain the two dimensional detector (2d detector) and the absorber in a fixed relative spatial relationship with respect to the beam focus of the linear accelerator, when the gantry is rotated, so that the central axis of the beam is essentially orthogonal to the 2d detector and the phantom axis of symmetry is parallel to or aligned with the central axis of the gantry rotation axis.

Owner:MOETTELI JOHN BRENT

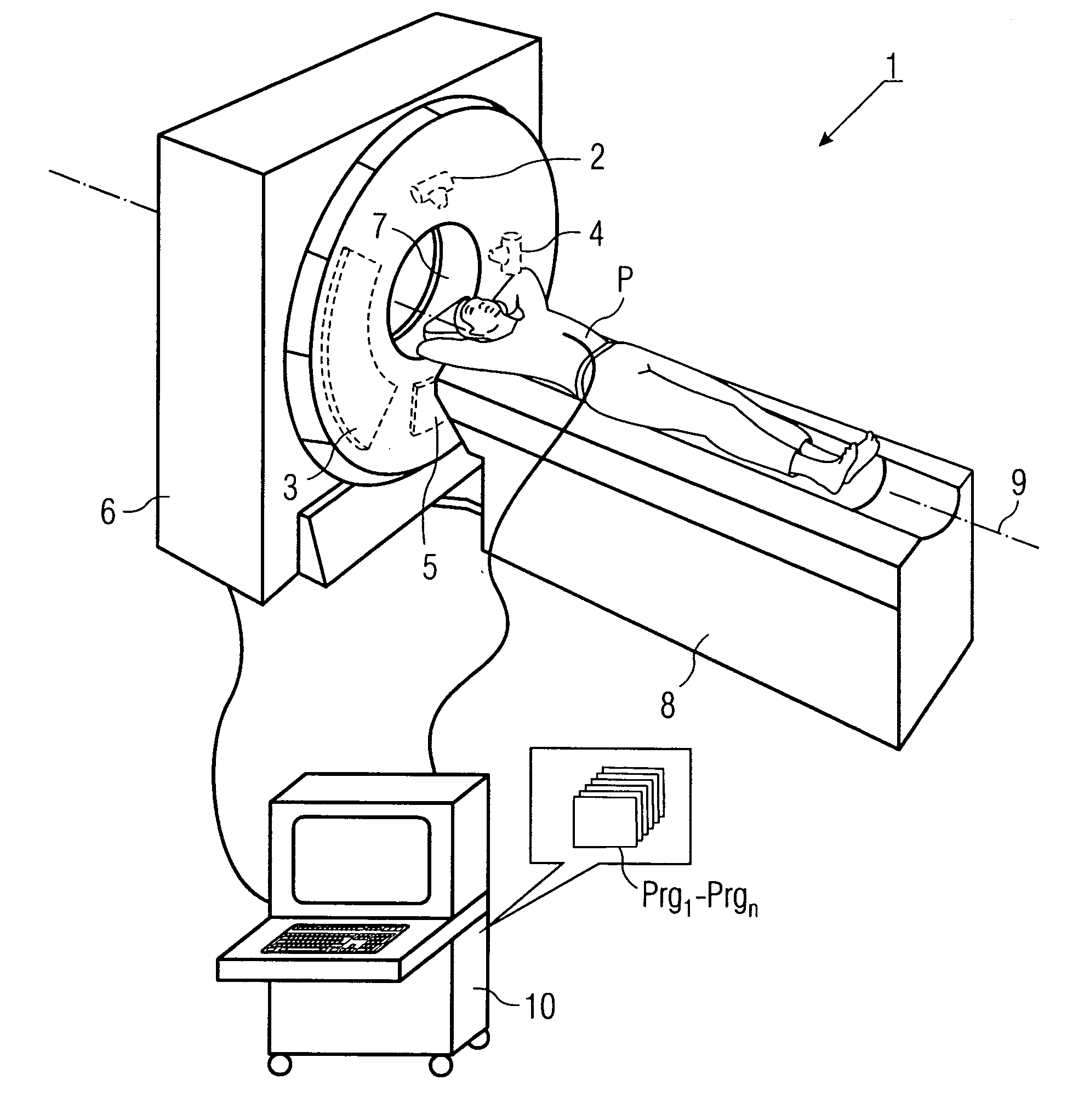

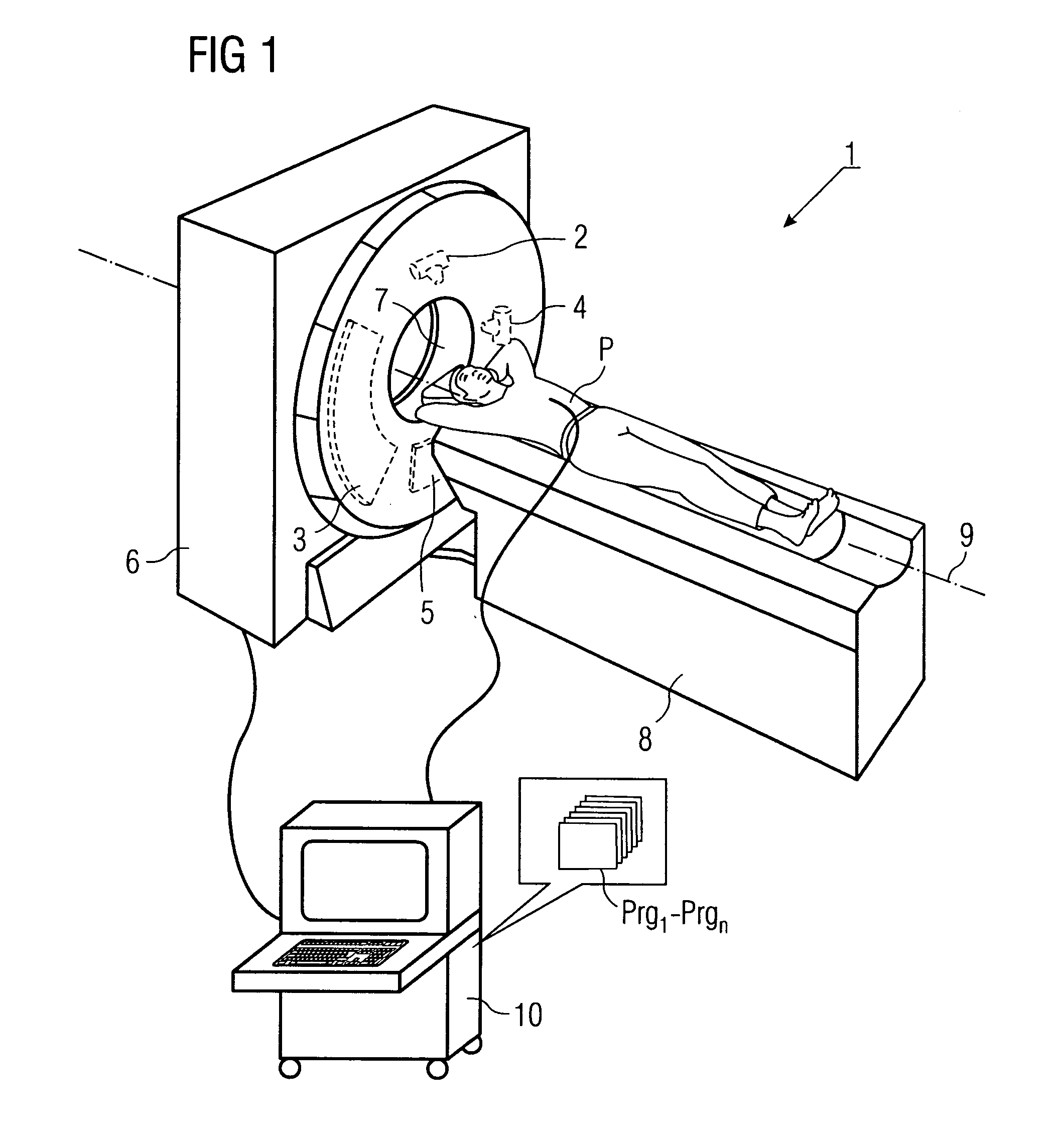

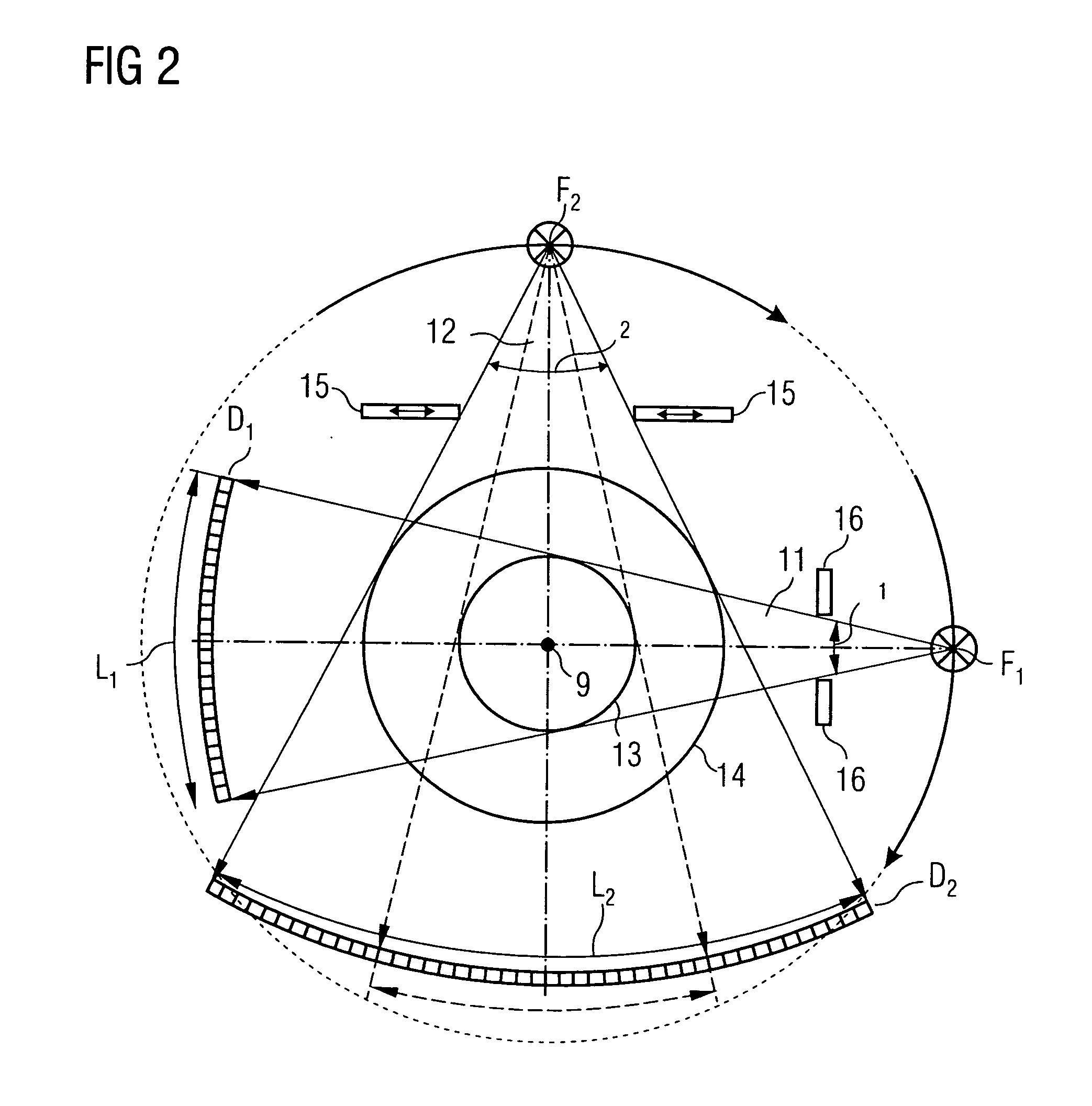

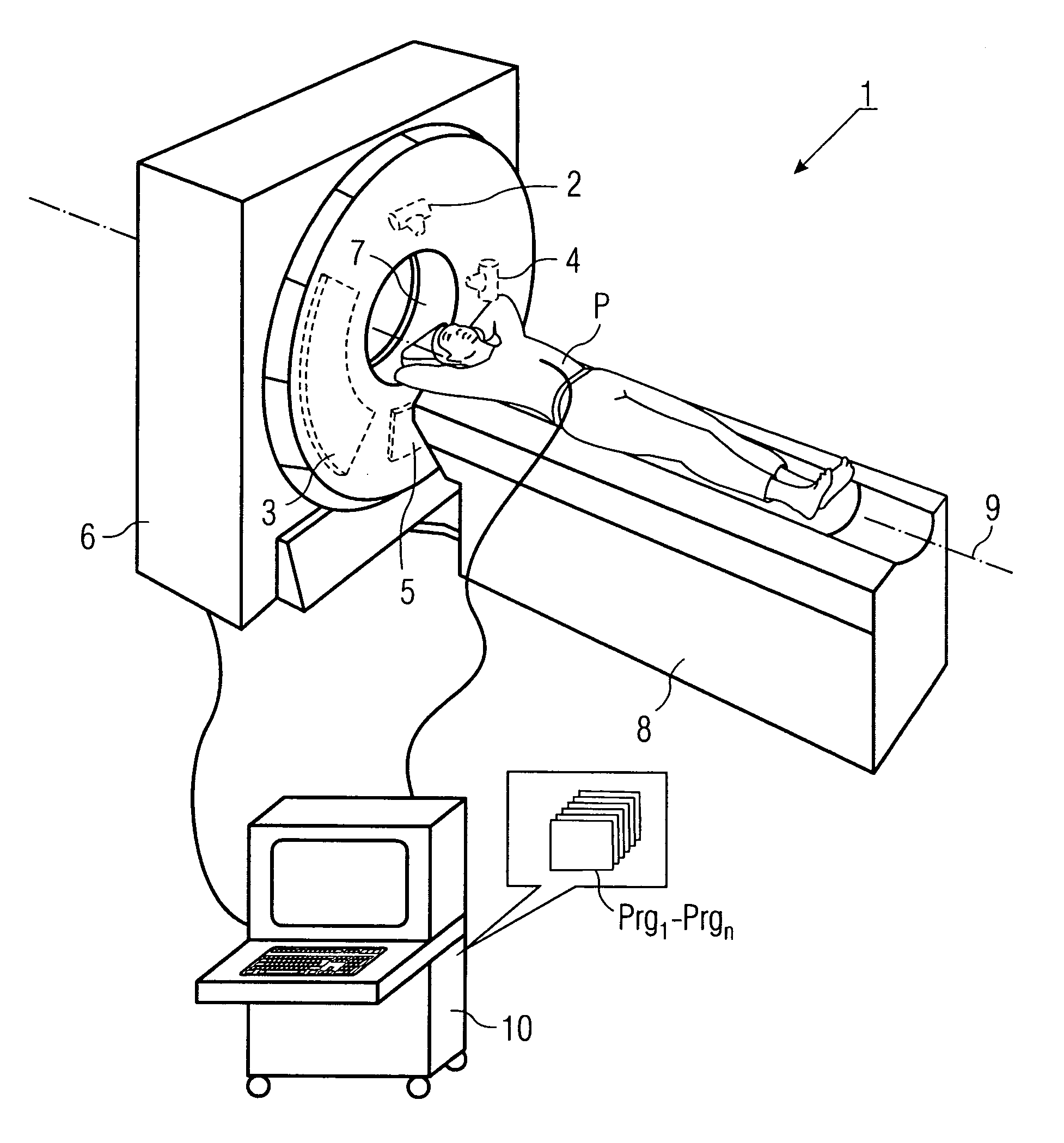

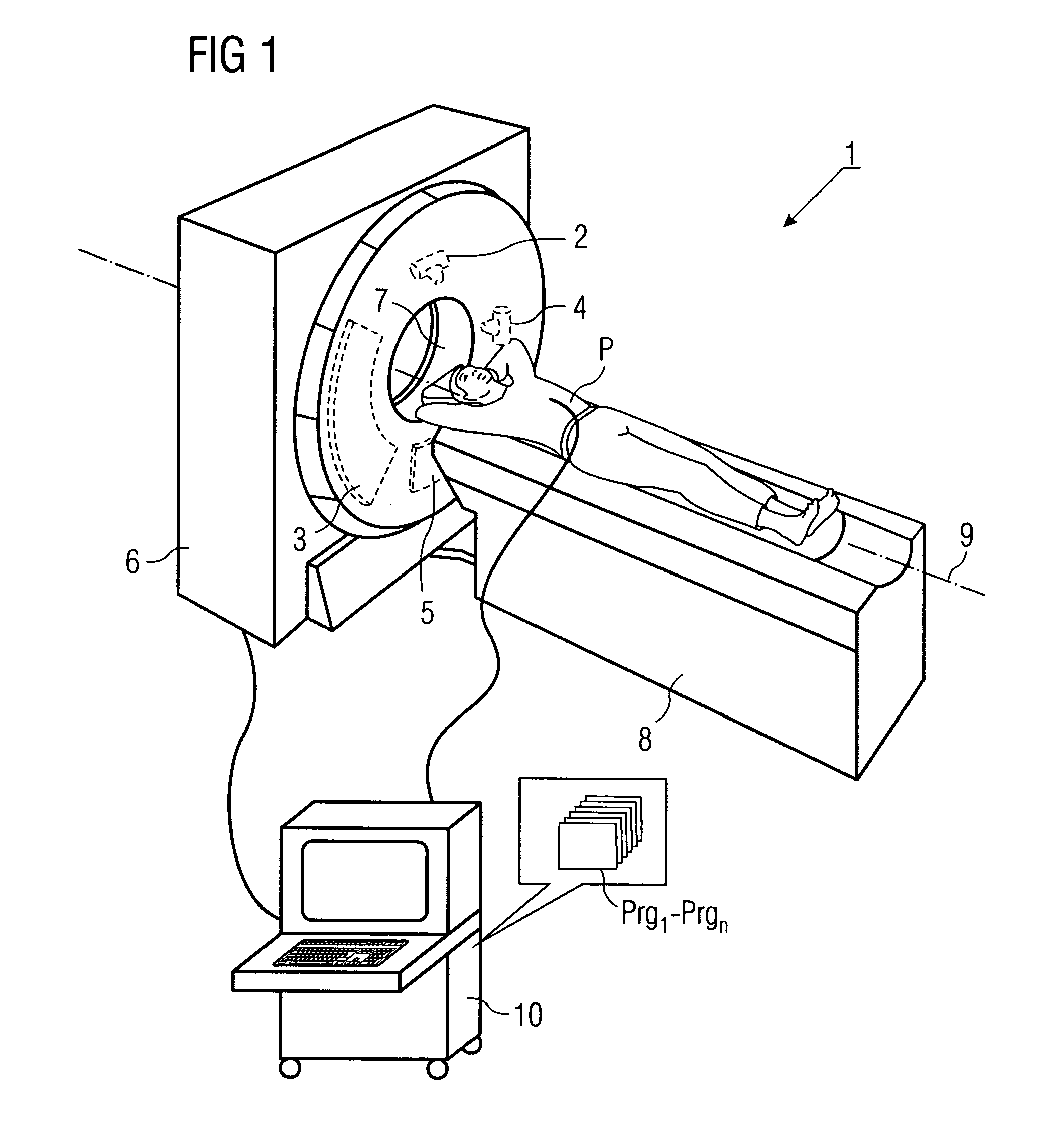

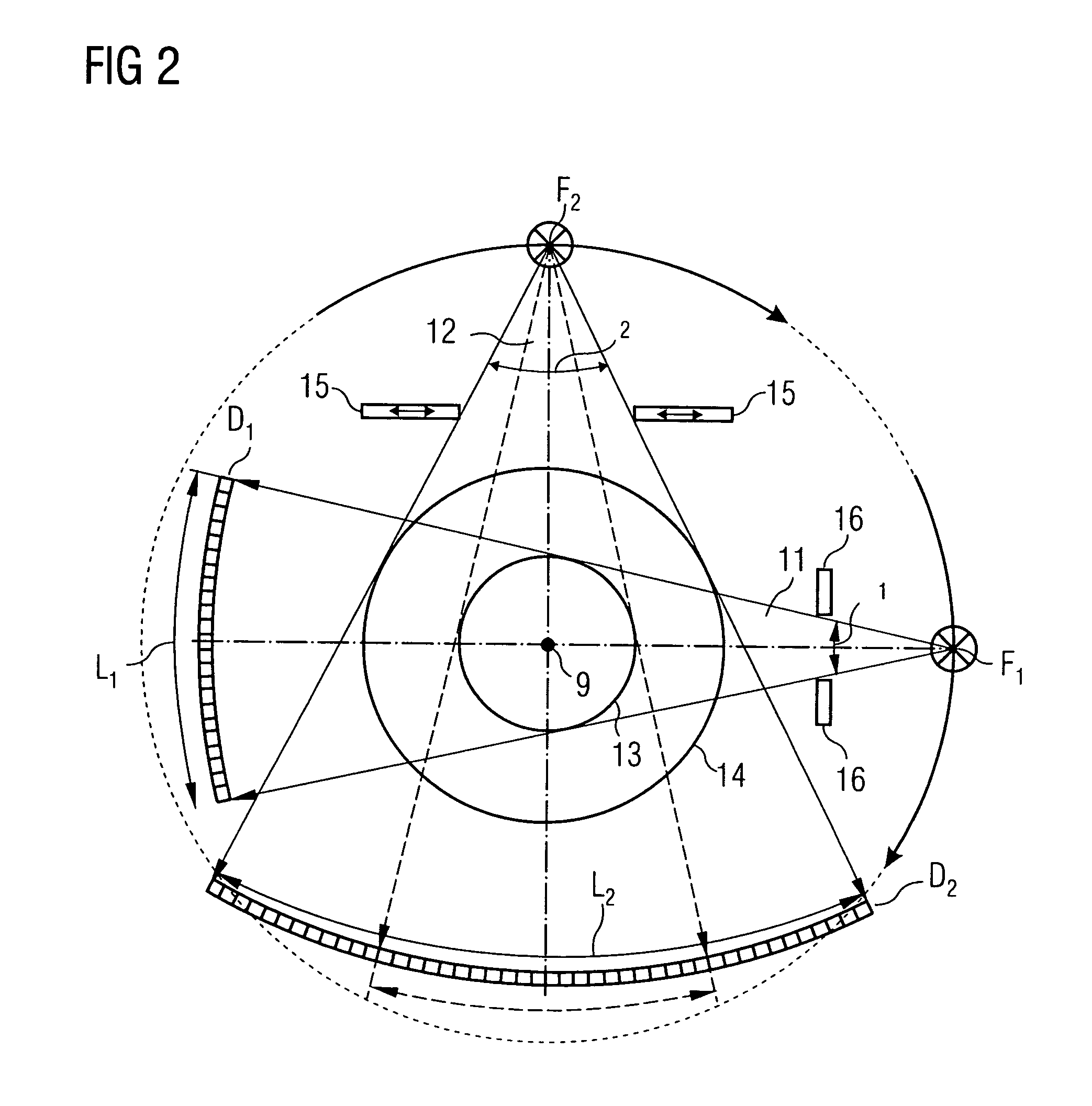

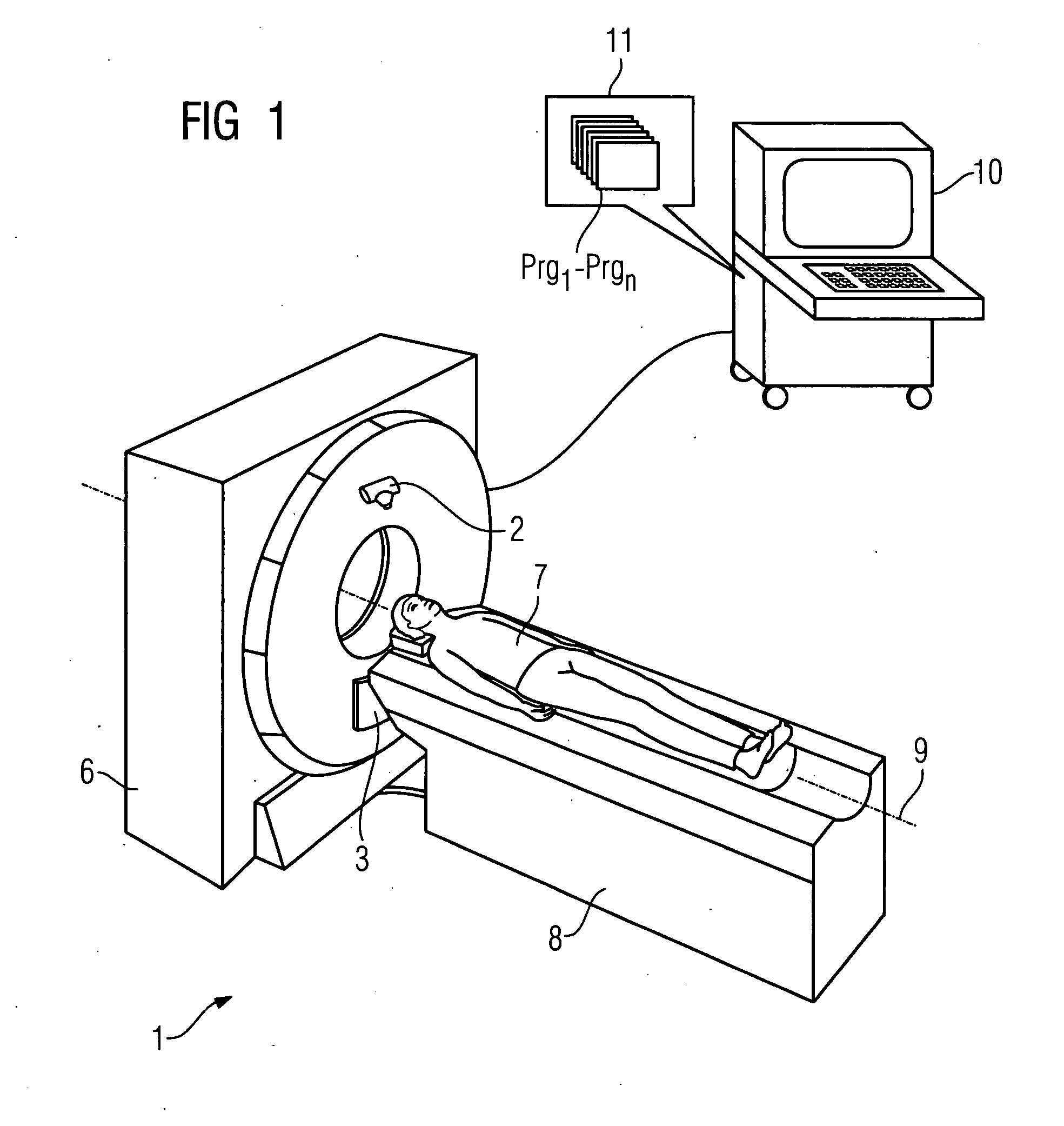

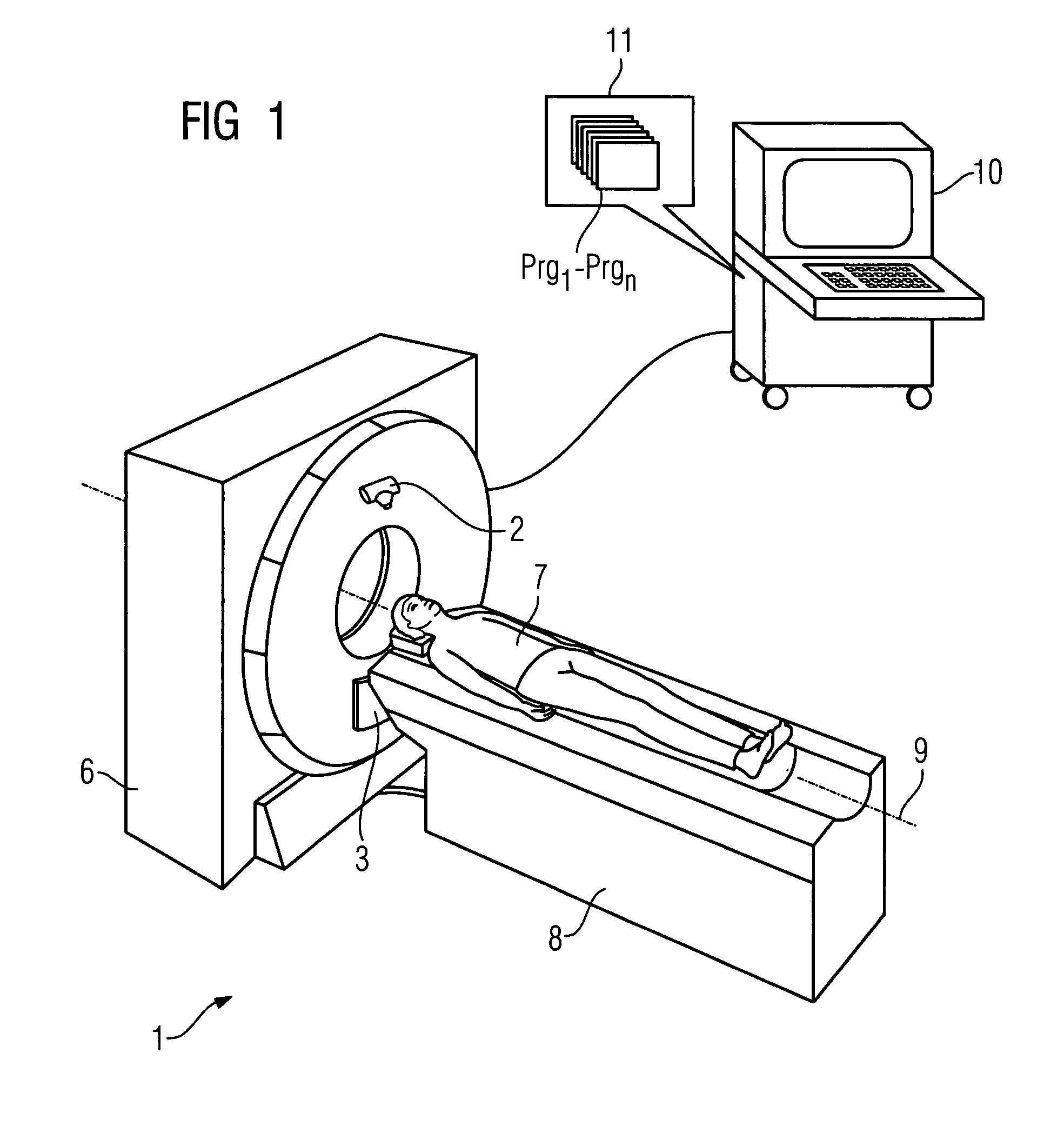

Method for production of tomographic section images of a periodically moving object with a number of focus detector combinations

InactiveUS20050111622A1Reduce dose loadOptimize timingRadiation/particle handlingComputerised tomographsTime correlationCt scanners

A method and CT scanner are proposed for the production of tomographic section images, in particular X-ray CT images, of a periodically moving object with periodically changing movement and rest phases. For scanning, a number of focus detector combinations with flat detectors are moved on coaxial spiral paths and movement signals from the moving object are measured at the same time in order to detect movement and rest phases. Further, the time correlation between the movement data and the detector output data stored and axial segment image stacks are then reconstructed independently of one another from sub-segments of the spiral paths using the detector output data from each detector which represent a rest phase of the moving object. Additionally, segment image stacks from the n spiral paths of the n focus detector combinations at the correct time are added up in a complementary angle form and in layers to form 180° tomography section images. The axial segment image stacks are reconstructed in a first step from double-inclined reconstruction planes. Further, in a second step, they are reformatted to produce axial segment image stacks, and detector data from a number of successive movement periods are used for this purpose.

Owner:SIEMENS HEALTHCARE GMBH

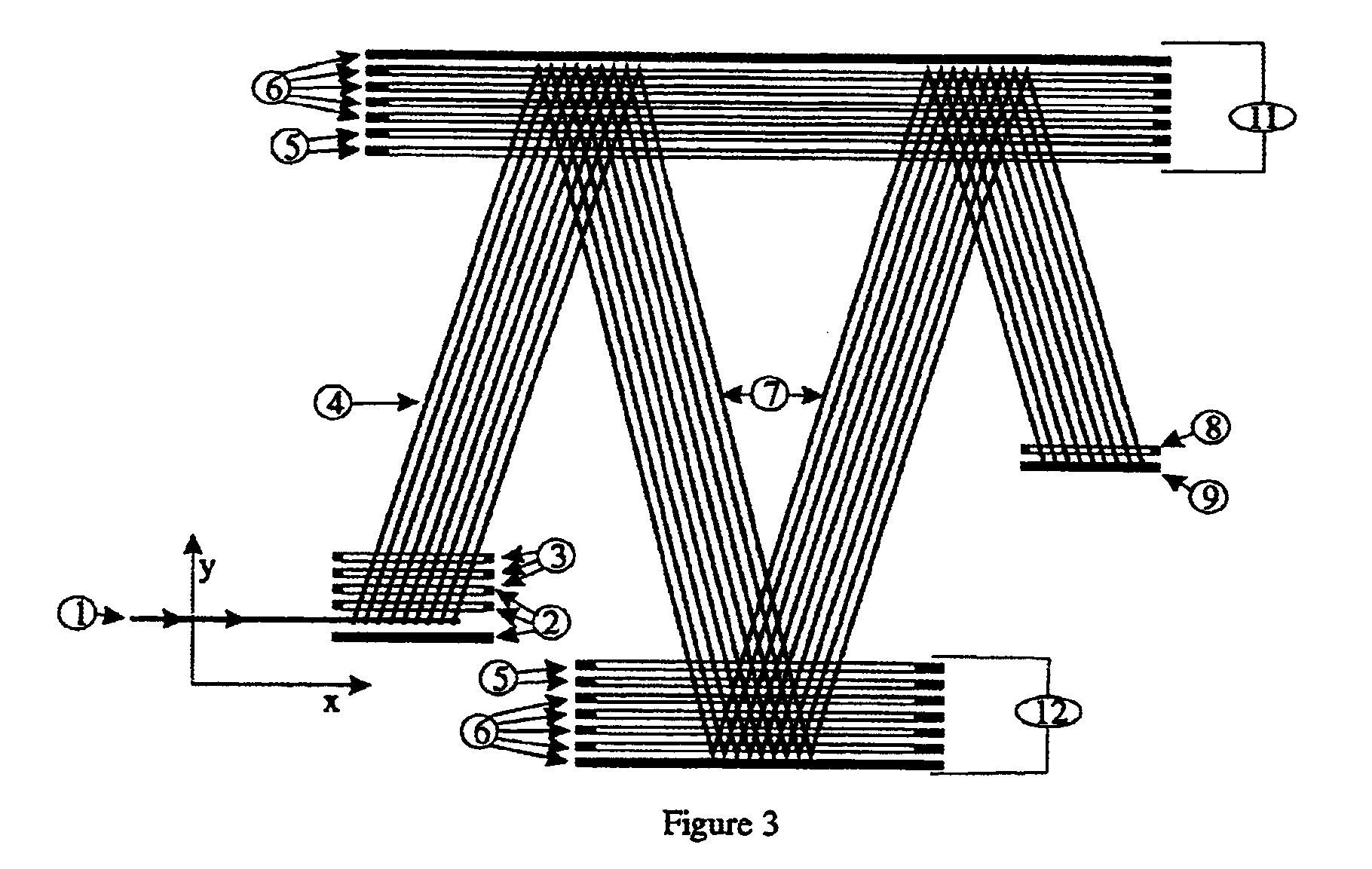

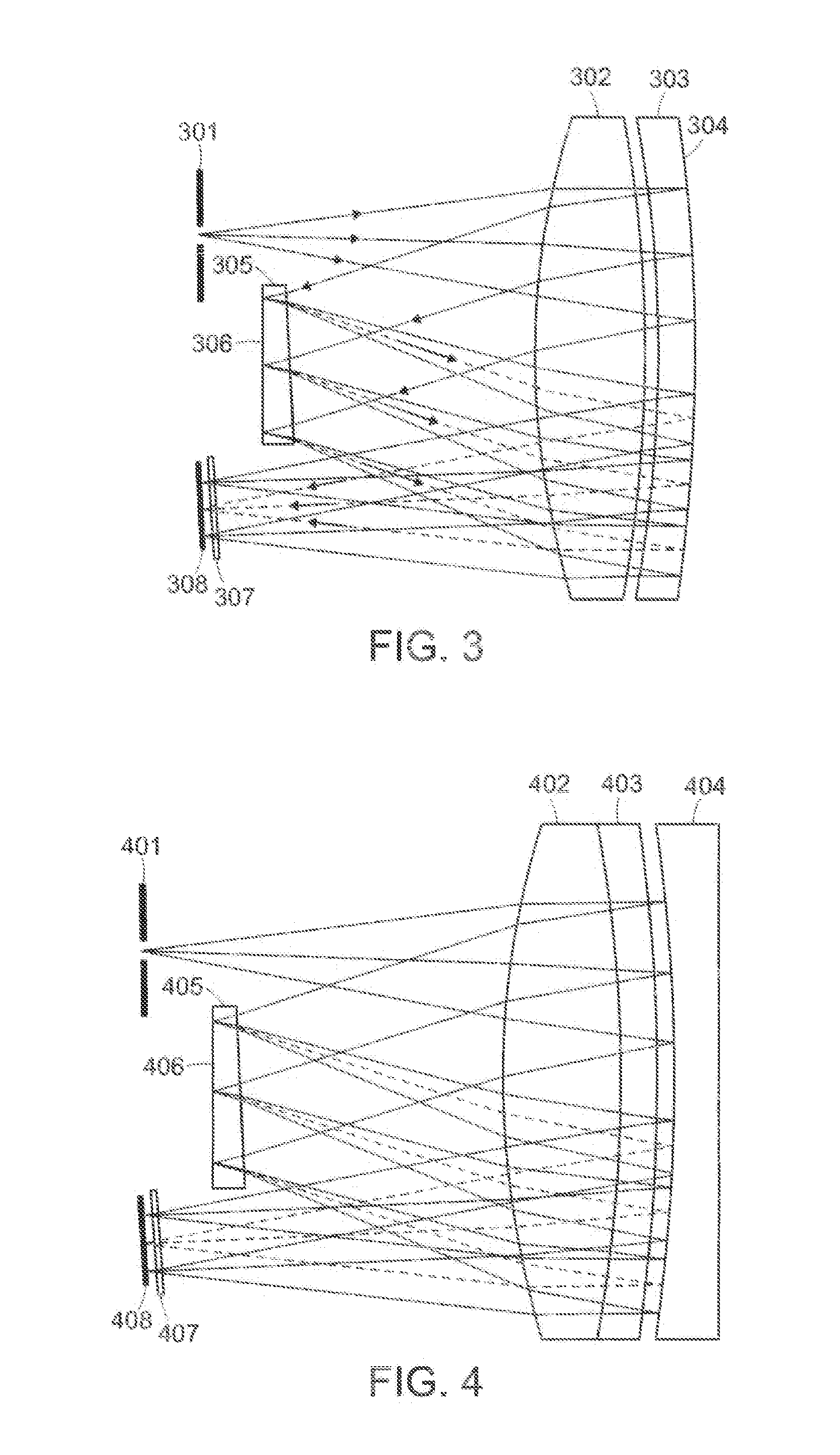

Visible-infrared plane grating imaging spectrometer

ActiveUS20150021480A1Easy to makeRadiation pyrometrySpectrum investigationFlat detectorImaging spectrometer

An imaging spectrometer, covering the visible through infrared wavelengths, which disperses the light by a plane diffraction grating behind a wedged optical element. This design uses an achromatic doublet lens with a reflective coating on its convex back surface to produce the spectra on a flat detector. Spatial keystone distortion and spectral smile are controlled to less than one tenth of a pixel over the full wavelength range, facilitating the use of simple retrieval algorithms.

Owner:MASSACHUSETTS INST OF TECH

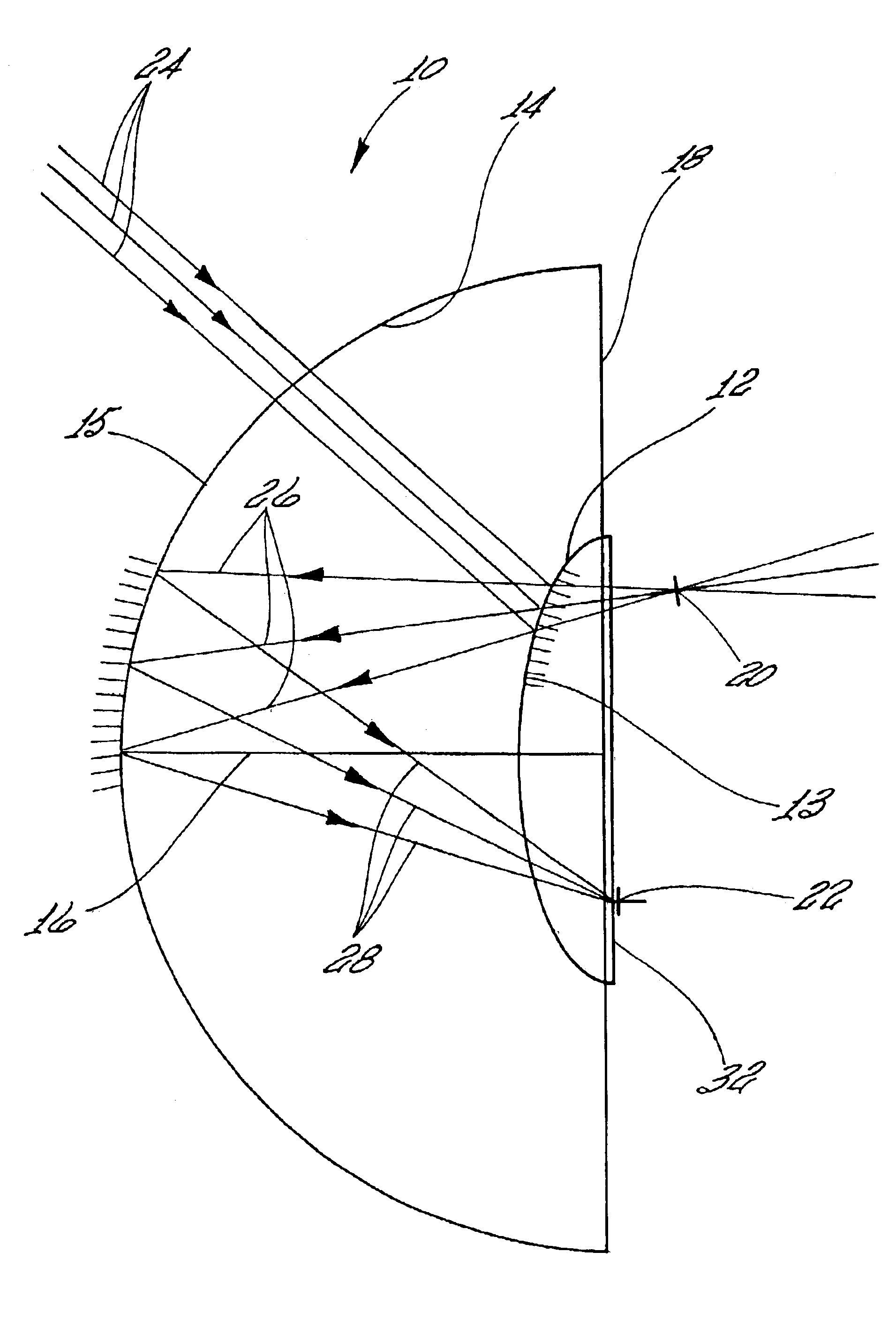

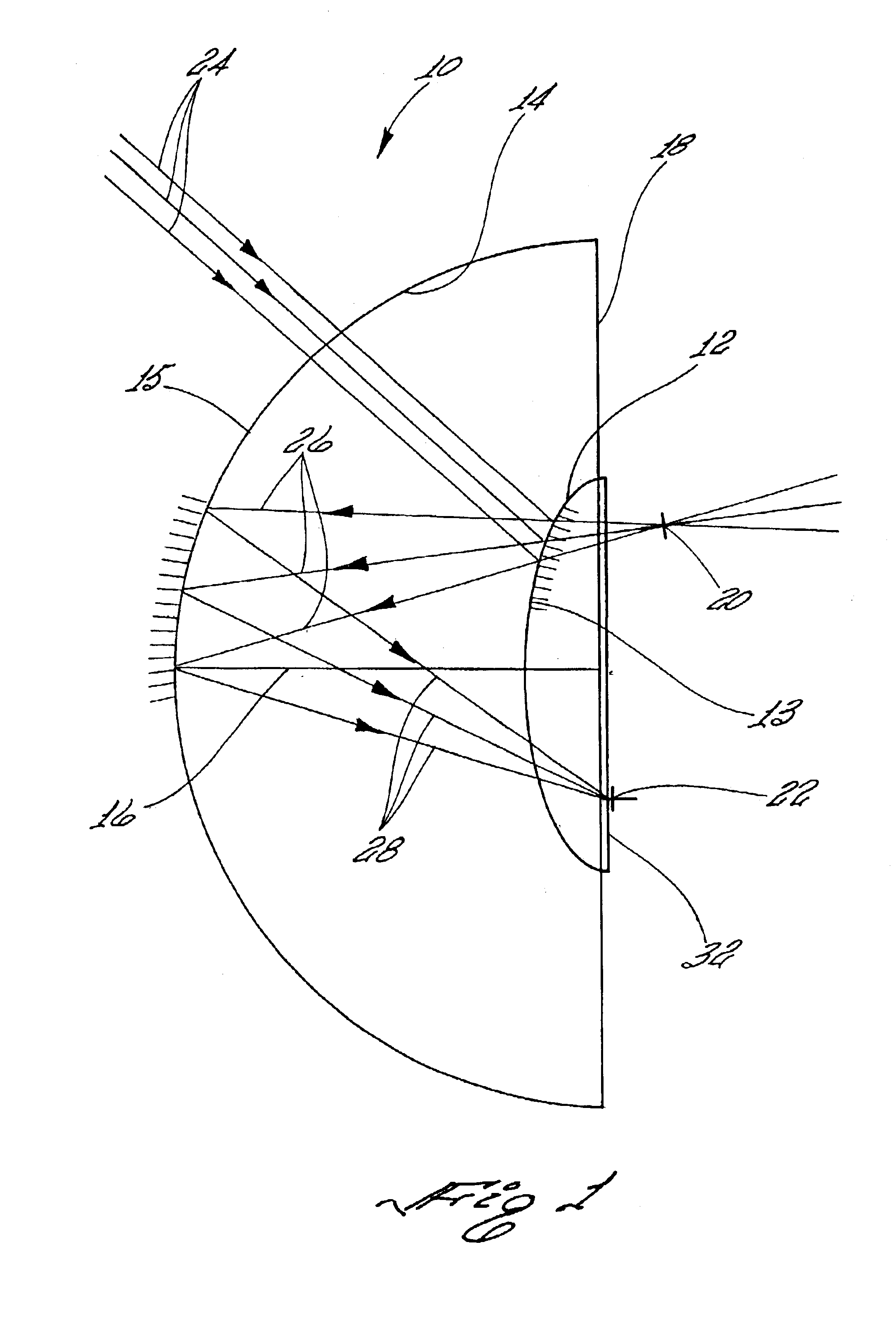

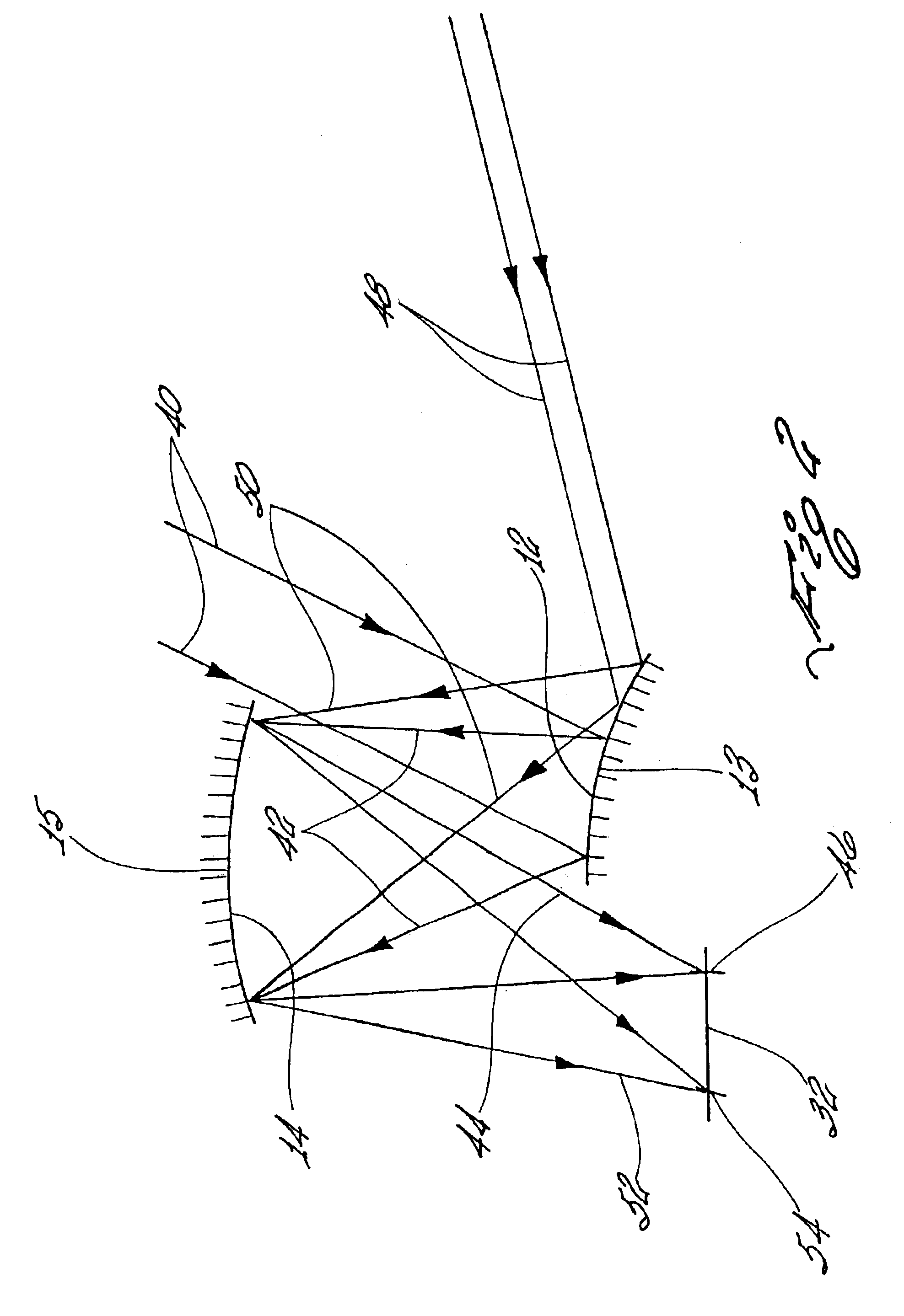

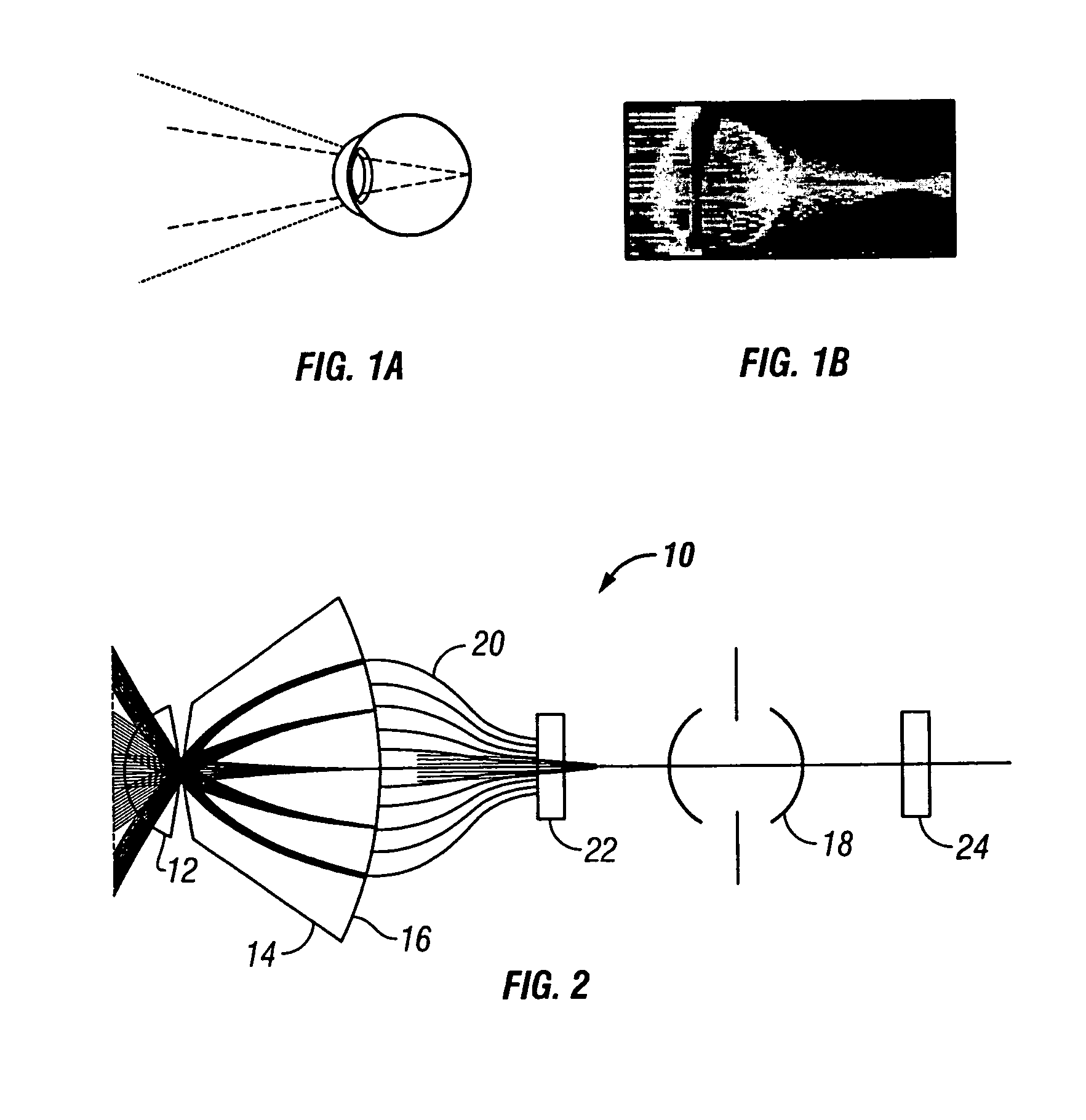

Confocal ellipsoidal mirror system for wide field of view imaging

An optical system having a pair of ellipsoidal shaped reflective surfaces or mirrors which receive light from an object and provide wide field view imaging for the object. The optical system directs the light onto a flat detector to a record a wide field of view image of the object on the flat detector.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for production of tomographic section images of a periodically moving object with a number of focus detector combinations

InactiveUS7039152B2Optimize timingNone is suitable for purposeRadiation/particle handlingComputerised tomographsTime correlationCt scanners

A method and CT scanner are proposed for the production of tomographic section images, in particular X-ray CT images, of a periodically moving object with periodically changing movement and rest phases. For scanning, a number of focus detector combinations with flat detectors are moved on coaxial spiral paths and movement signals from the moving object are measured at the same time in order to detect movement and rest phases. Further, the time correlation between the movement data and the detector output data stored and axial segment image stacks are then reconstructed independently of one another from sub-segments of the spiral paths using the detector output data from each detector which represent a rest phase of the moving object. Additionally, segment image stacks from the n spiral paths of the n focus detector combinations at the correct time are added up in a complementary angle form and in layers to form 180° tomography section images. The axial segment image stacks are reconstructed in a first step from double-inclined reconstruction planes. Further, in a second step, they are reformatted to produce axial segment image stacks, and detector data from a number of successive movement periods are used for this purpose.

Owner:SIEMENS HEALTHCARE GMBH

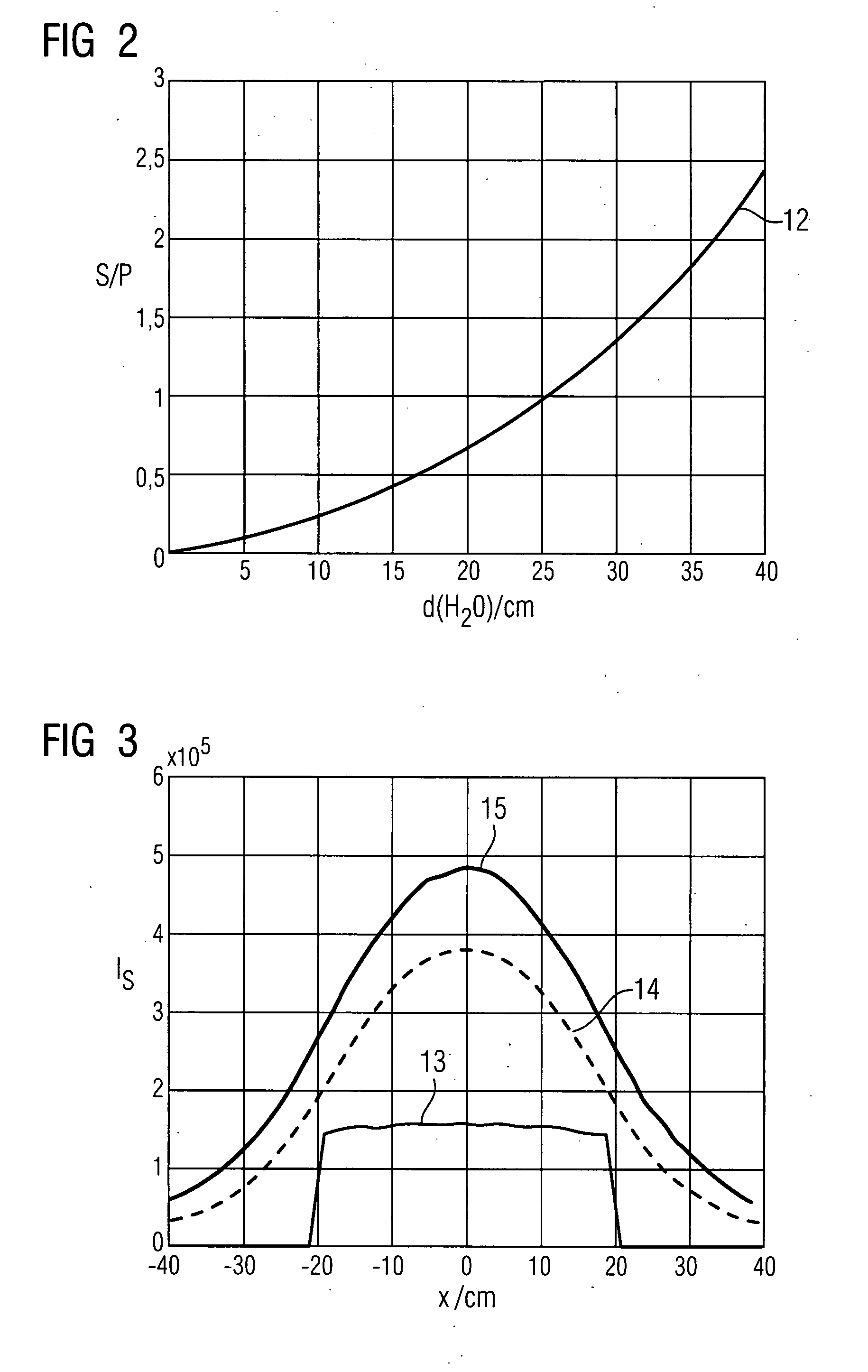

Method for combined bone hardening and scattered radiation correction in X-ray computed tomography

InactiveUS20080159469A1Accurate methodGood compensationMaterial analysis using wave/particle radiationRadiation/particle handlingSoft x rayArithmetic logic unit

The invention relates to a method for combined bone hardening and scattered radiation correction in X-ray computed tomography of a heterogeneous object with a CT system comprising an X-ray source moved around an object, a flat detector with a large number of distributed detector elements which detect measuring beams from a focal point of the X-ray tube, and a control and arithmetic-logic unit—by iterative reconstruction and segmented vectorial reprojection calculation, wherein a scattered radiation correction and a radiation hardening correction are carried out in each iteration cycle for at least two different material components of the object being examined. The invention also relates to an X-ray CT system for carrying out this method.

Owner:SIEMENS HEALTHCARE GMBH

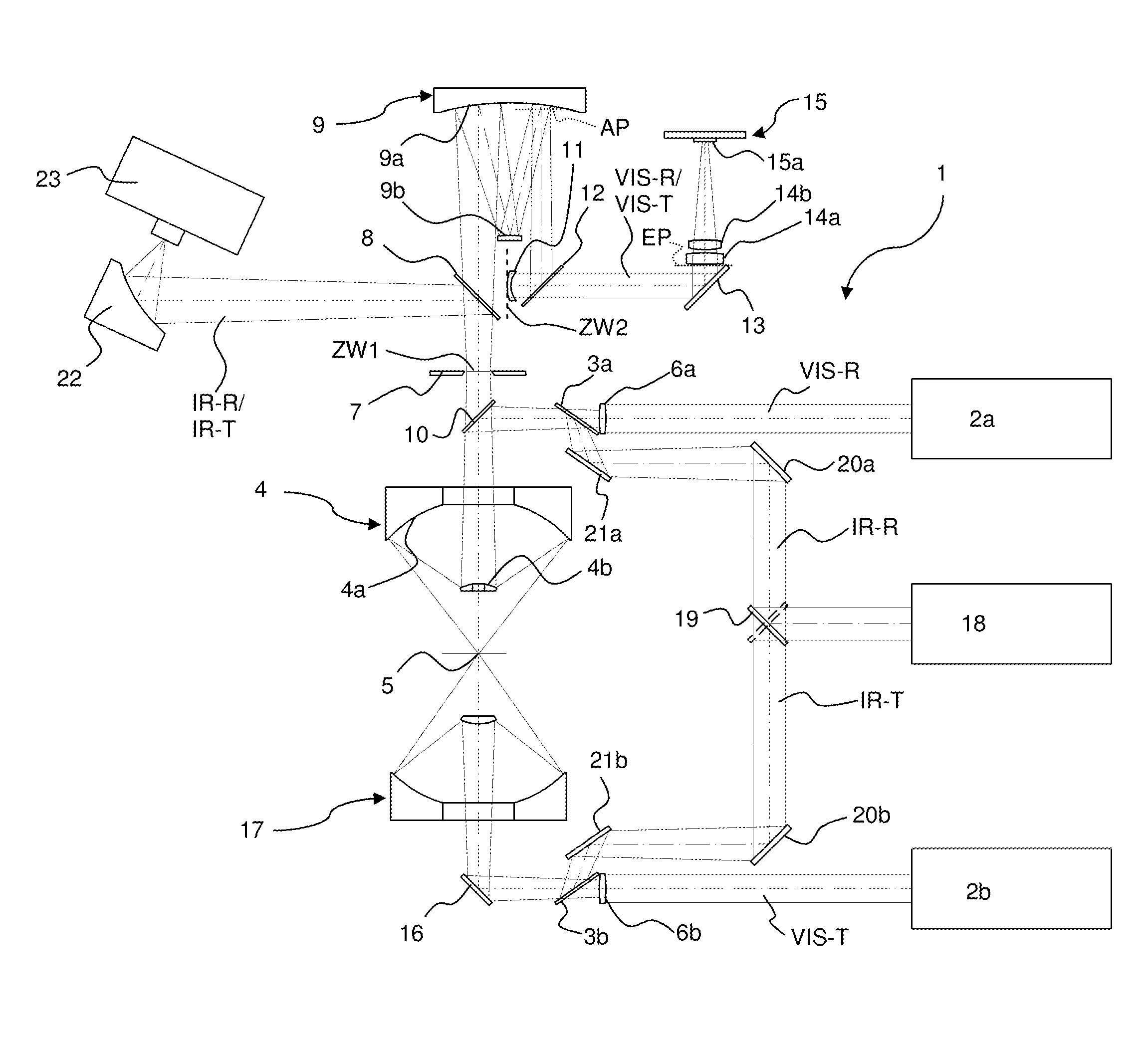

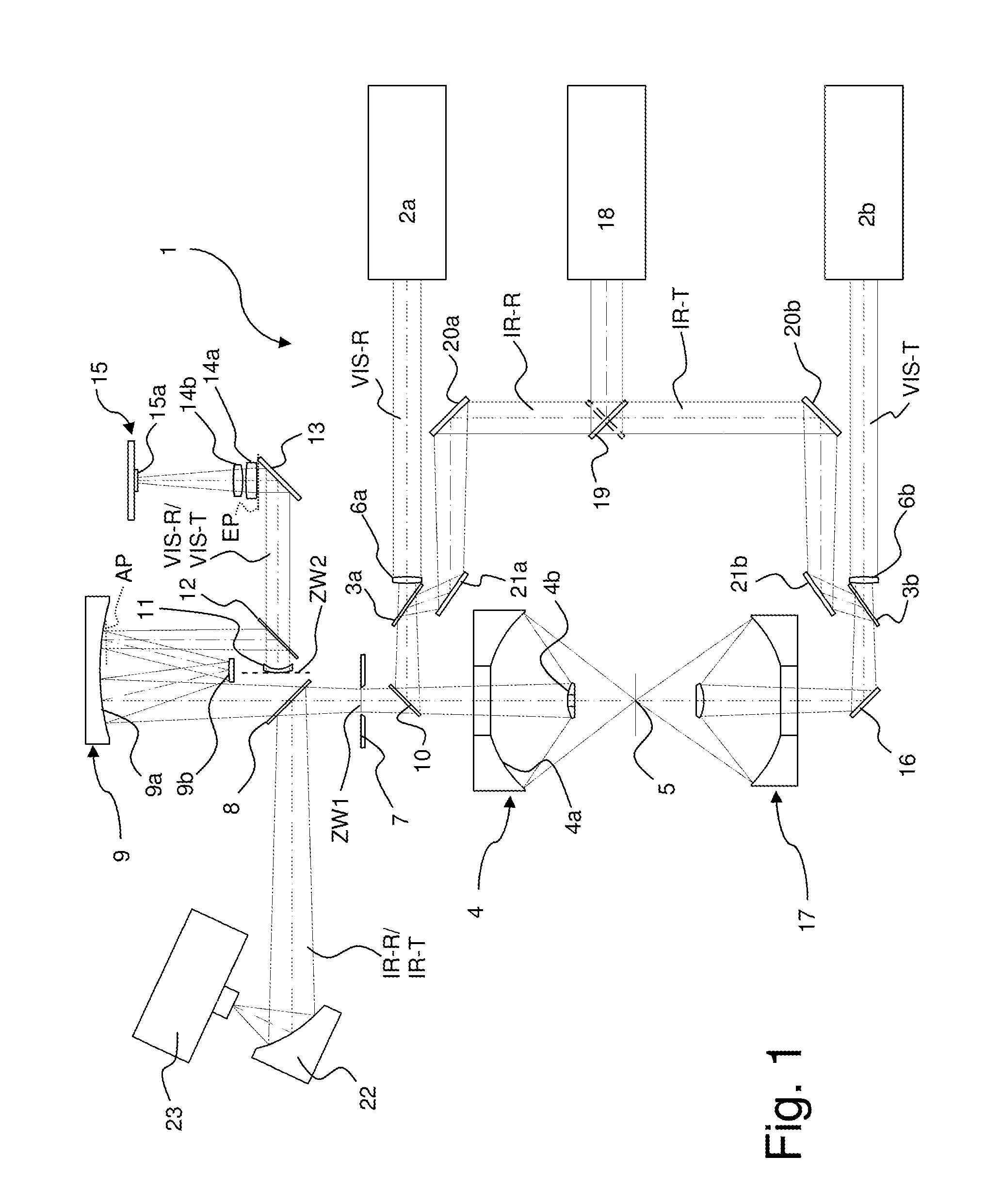

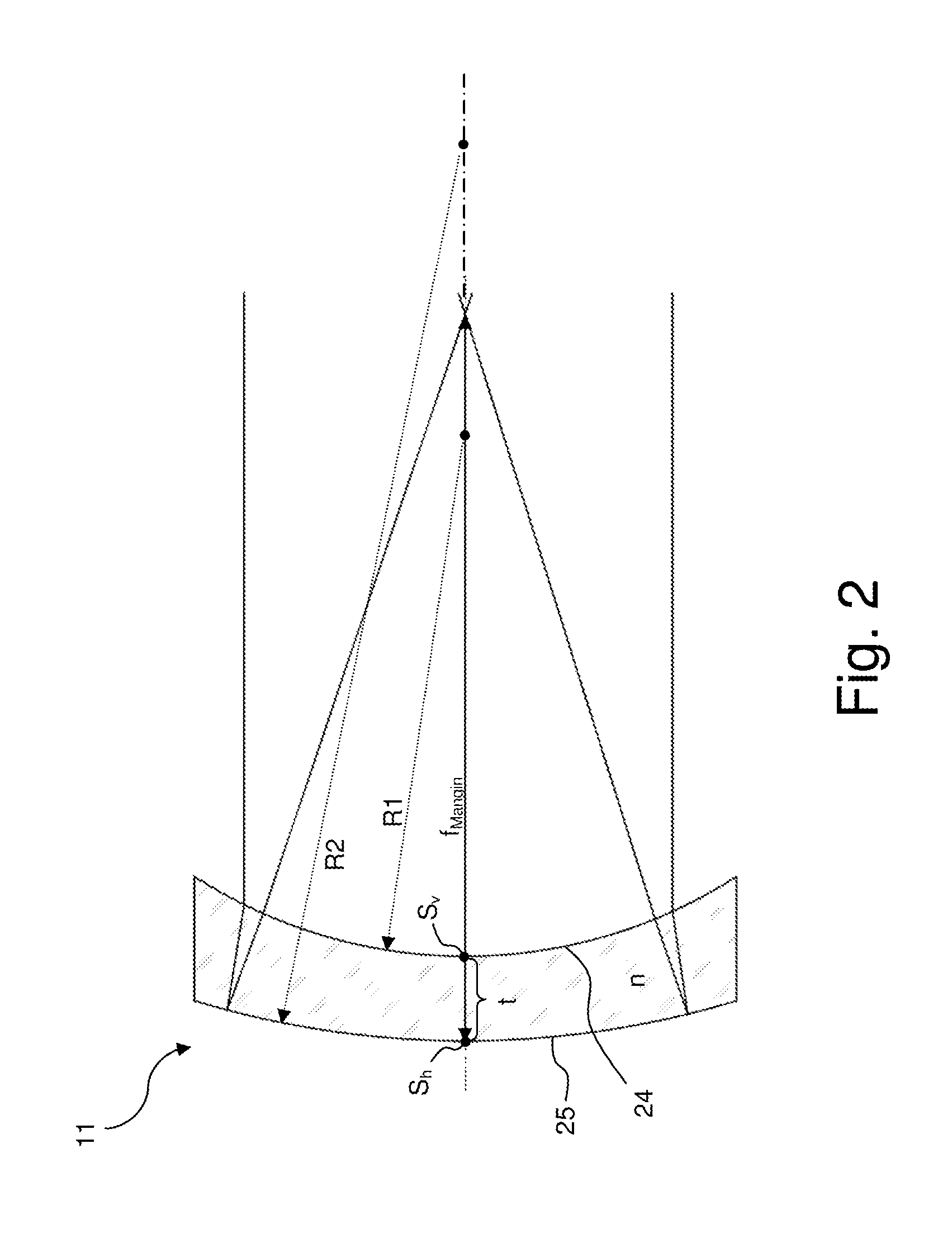

IR microscope with image field curvature compensation, in particular with additional illumination optimization

ActiveUS20130188034A1Easy to useAvoid chromatic aberrationRadiation pyrometryMaterial analysis by optical meansMangin mirrorFlat detector

An IR microscope (1) is constituted such that, in an optical viewing mode in a beam path of visible light (VIS-R, VIS-T), a first intermediate focus (ZW1) is imaged onto a flat detector surface (15a) of a camera. The IR microscope (1) is constituted such that, in the beam path of the visible light (VIS-R, VIS-T), the first intermediate focus (ZW1) is imaged onto a second intermediate focus (ZW2), and, in the second intermediate focus (ZW2), a Mangin mirror (11) is disposed that corrects a field curvature of the Cassegrain objective (4). The invention provides an IR microscope in which the field curvature generated by the Cassegrain objective is corrected in a simple manner in the optical viewing mode when detection is performed using a flat detector and without restricting the spectral range of the IR microscope.

Owner:BRUKER OPTICS GMBH & CO KG

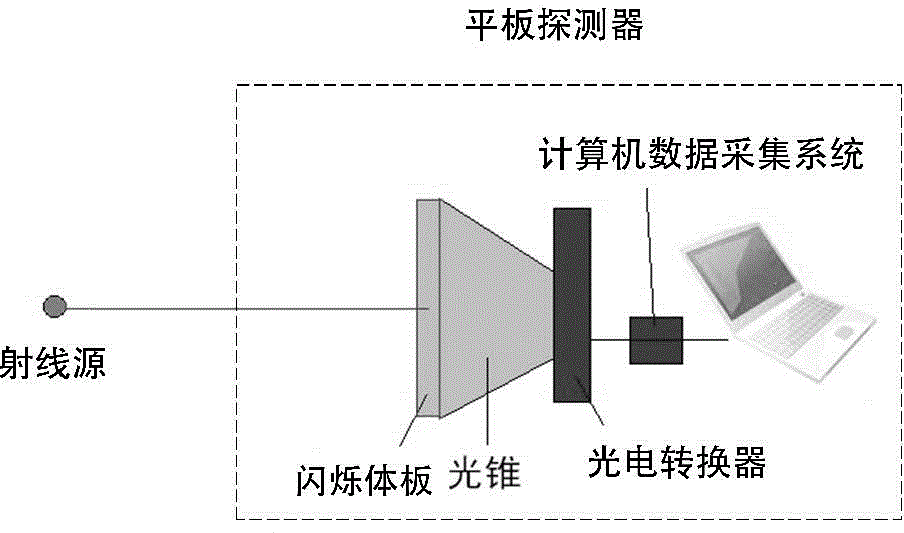

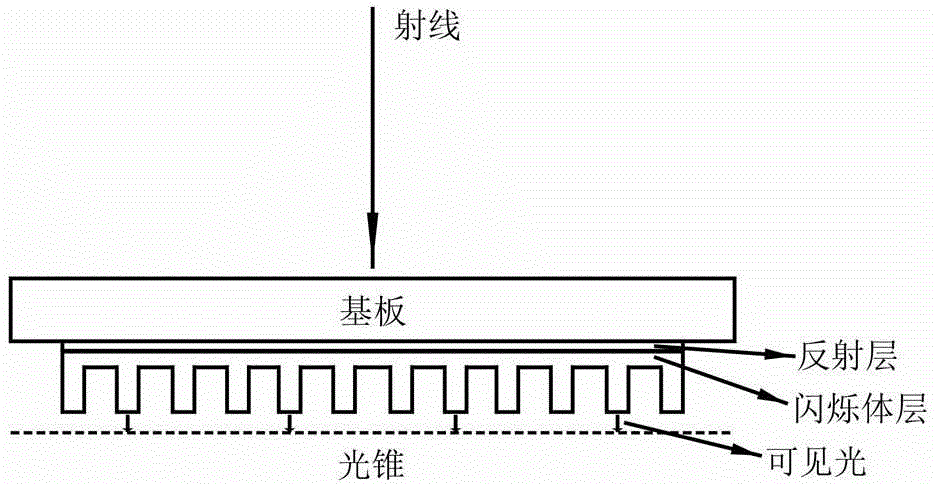

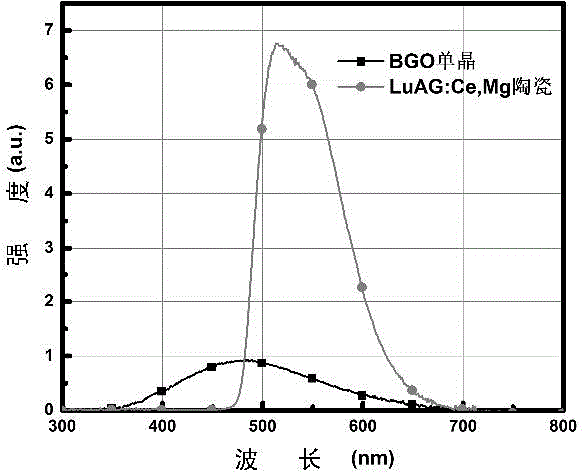

Scintillator plate for ray detection flat detector and preparation method for the same

ActiveCN106154302ASharp imaging with high spatial resolutionReduce maintenance costsRadiation intensity measurementFlat detectorMedical diagnosis

The invention discloses a scintillator plate for a ray detection flat and a preparation method for the same. The scintillator plate comprises a substrate, a scintillator layer and a reflection layer clamped between the substrate and the scintillator layer; a composition chemical formula of the scintillator layer is (Lu(1-x-y)CexAy)3Al5O12; available ions for A case comprise at least one of Ca2+, Mg2+, Sr2+, Ba2+, Li+, Na+, and K+, 0.001<=x<=0.05, 0.0005<=y<=0.05. The (Lu,A)3Al5O12:Ce transparent ceramic ray flat detector has characteristics of high imaging sharp spatial resolution, low maintenance cost and long service life, and can be applied to devices using ray detection for medical diagnosis, nondestructive tests, public security, radiation dose detection, petroleum exploration, etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Customized alimentary canal support and moulding method and application method thereof

The invention discloses a customized alimentary canal support and a moulding method and an application method thereof. The moulding method comprises the steps of building a three-dimensional model of an alimentary canal structure of an individual object, and the alimentary canal structure comprises an alimentary canal stenosis or an obstruction part; performing data analysis and structure adjusting to the three-dimensional model; designing a virtual support by using a software; manufacturing a die corresponding to the inner contour of the support; and braiding a customized alimentary canal support on the die. The application method comprises the steps of delivering the customized support that has 4-6 different signs to a position to be planted. The support is successfully installed when the signs arrive at the designed installation position and the rotation angle under the monitor of an X-ray flat detector. In the complex alimentary canal obstruction areas like turnovers of stomach-duodenum and intestine-intestine, a traditional support fails easily, and the support provided by the invention can be used for a best treatment effect because of having the advantages like non-symmetry, high dissect precision, low internal stress, and difficult rotation shedding.

Owner:BEIJING FRIENDSHIP HOSPITAL CAPITAL MEDICAL UNIV +1

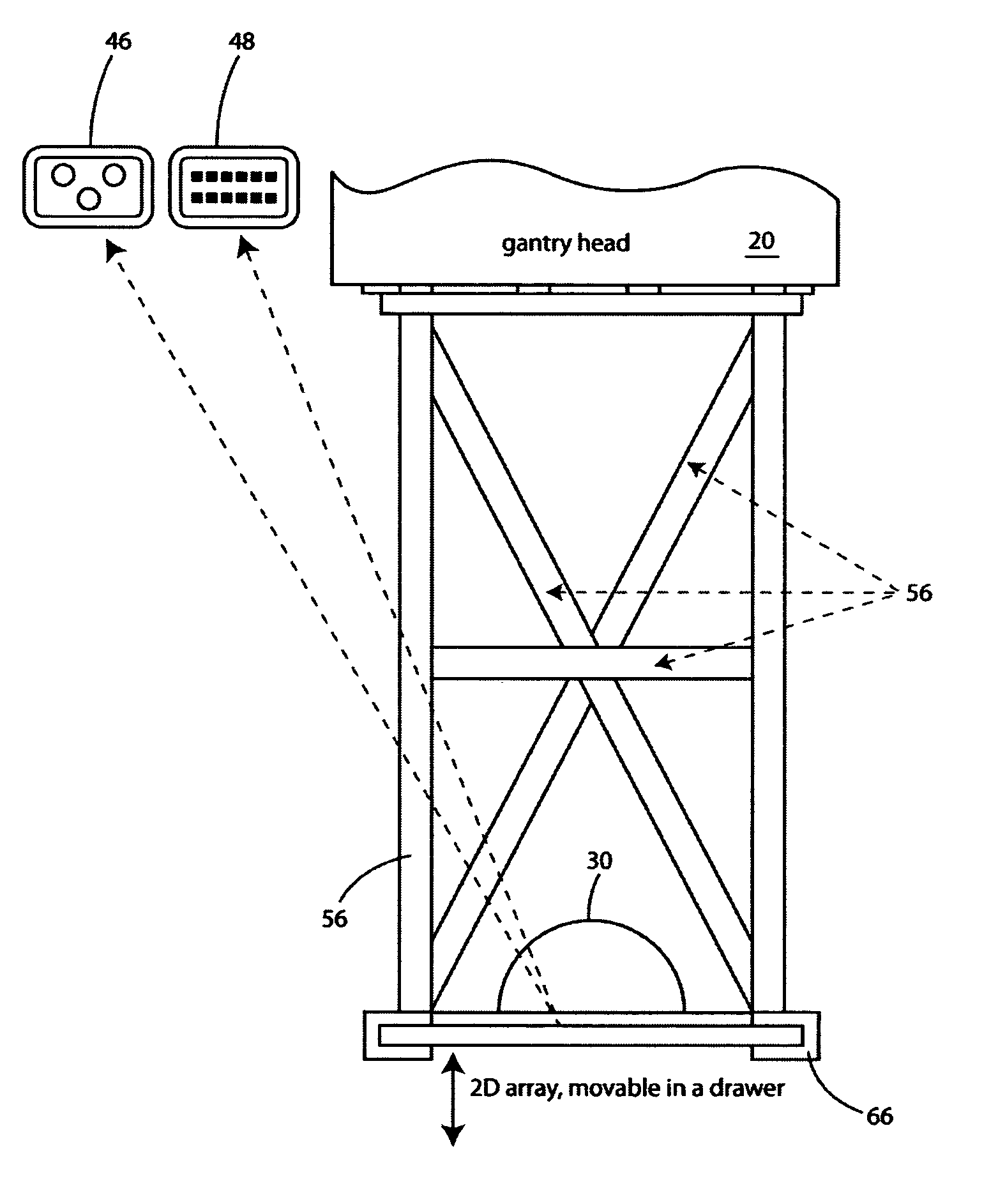

Rotationally symmetrical coherent verification phantom (virtual patient) with a flat detector disposed on a rotary axis integrated in a multi purpose QC-accessory

InactiveUS8921766B2Television system detailsMaterial analysis by optical meansTwo dimensional detectorAxis of symmetry

A quality control accessory (QC accessory) is provided which is adapted for use in linear accelerator quality control or in verification of an arbitrary isocentric radiation treatment plan of a patient or radiation sensitive body. The accessory includes an absorber, a detector and an optional orientation device. The absorber is rotationally symmetric, preferably spherical or hemispherical. The detector is adapted to be fixed in a stationary spatial relationship with respect to the absorber. The optional orientation device is adapted to maintain the two dimensional detector (2d detector) and the absorber in a fixed relative spatial relationship with respect to the beam focus of the linear accelerator, when the gantry is rotated, so that the central axis of the beam is essentially orthogonal to the 2d detector and the phantom axis of symmetry is parallel to or aligned with the central axis of the gantry rotation axis.

Owner:MOETTELI JOHN BRENT

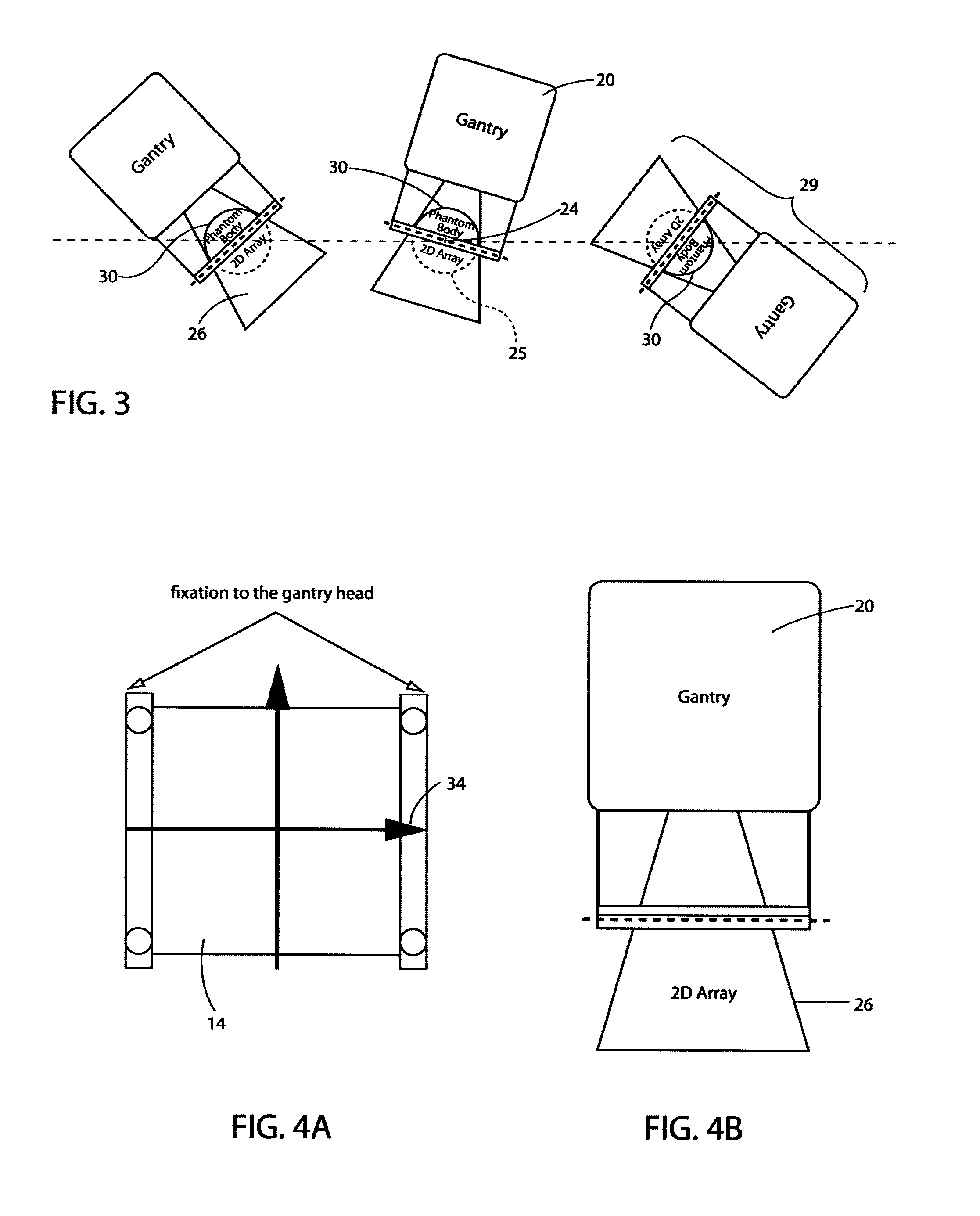

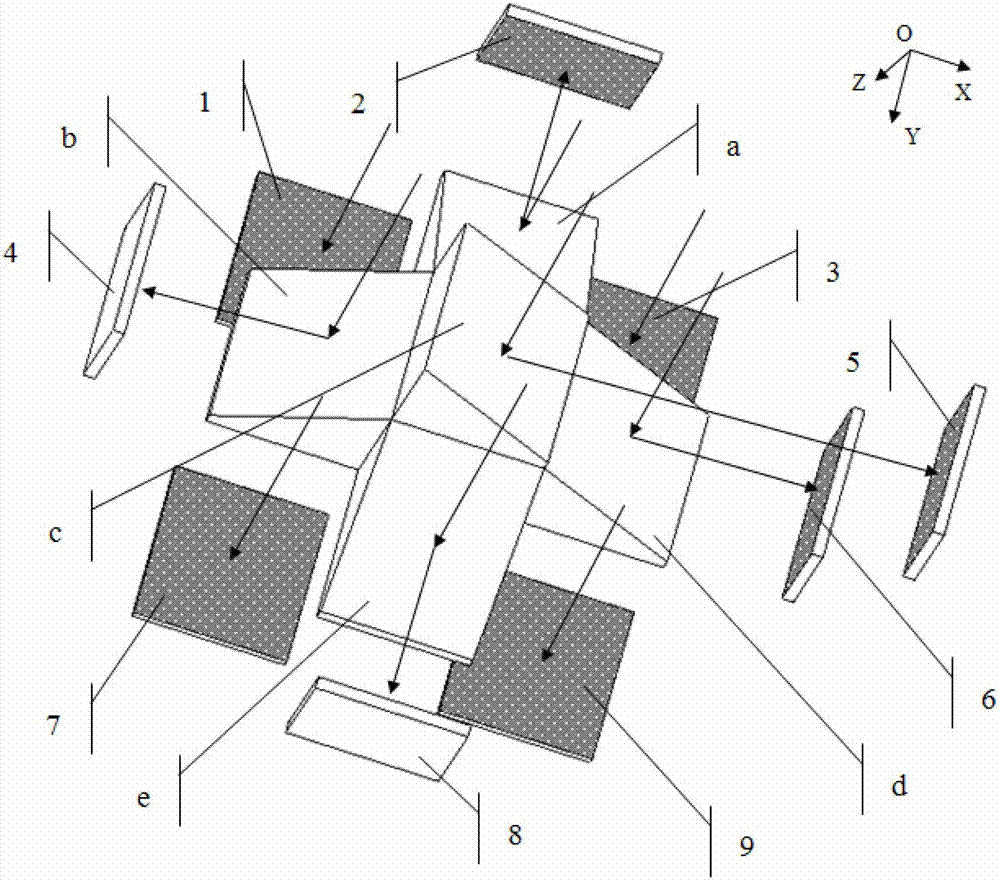

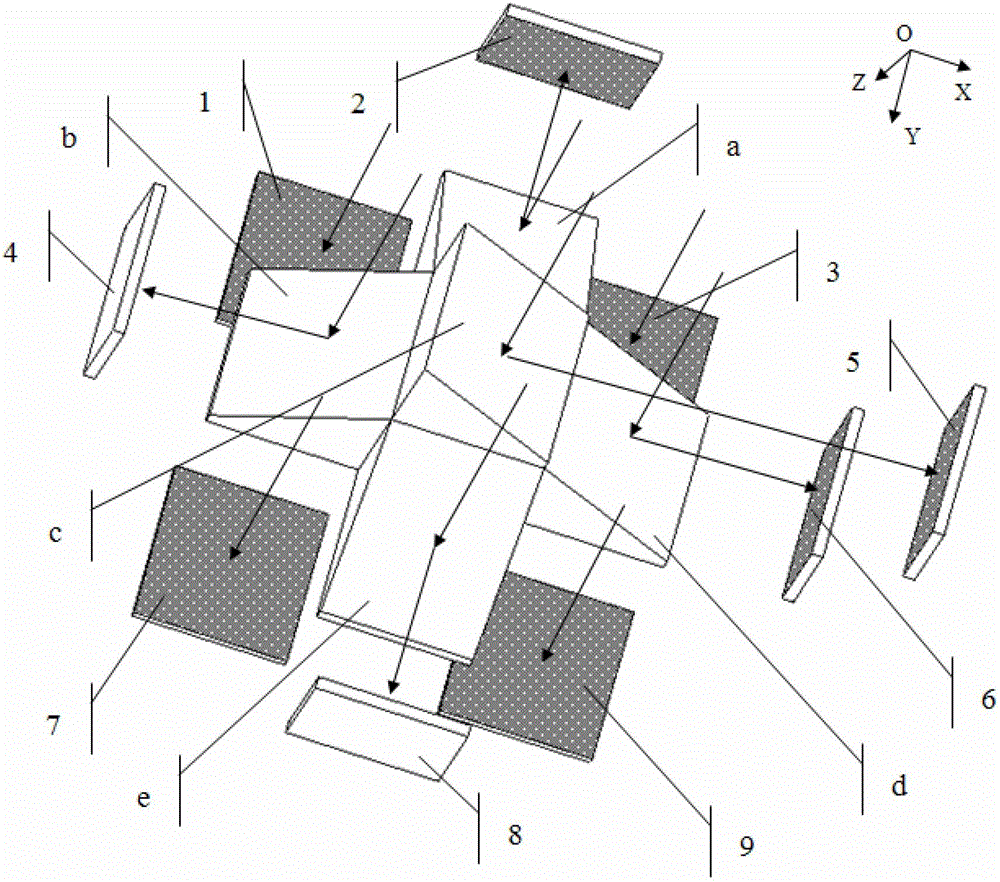

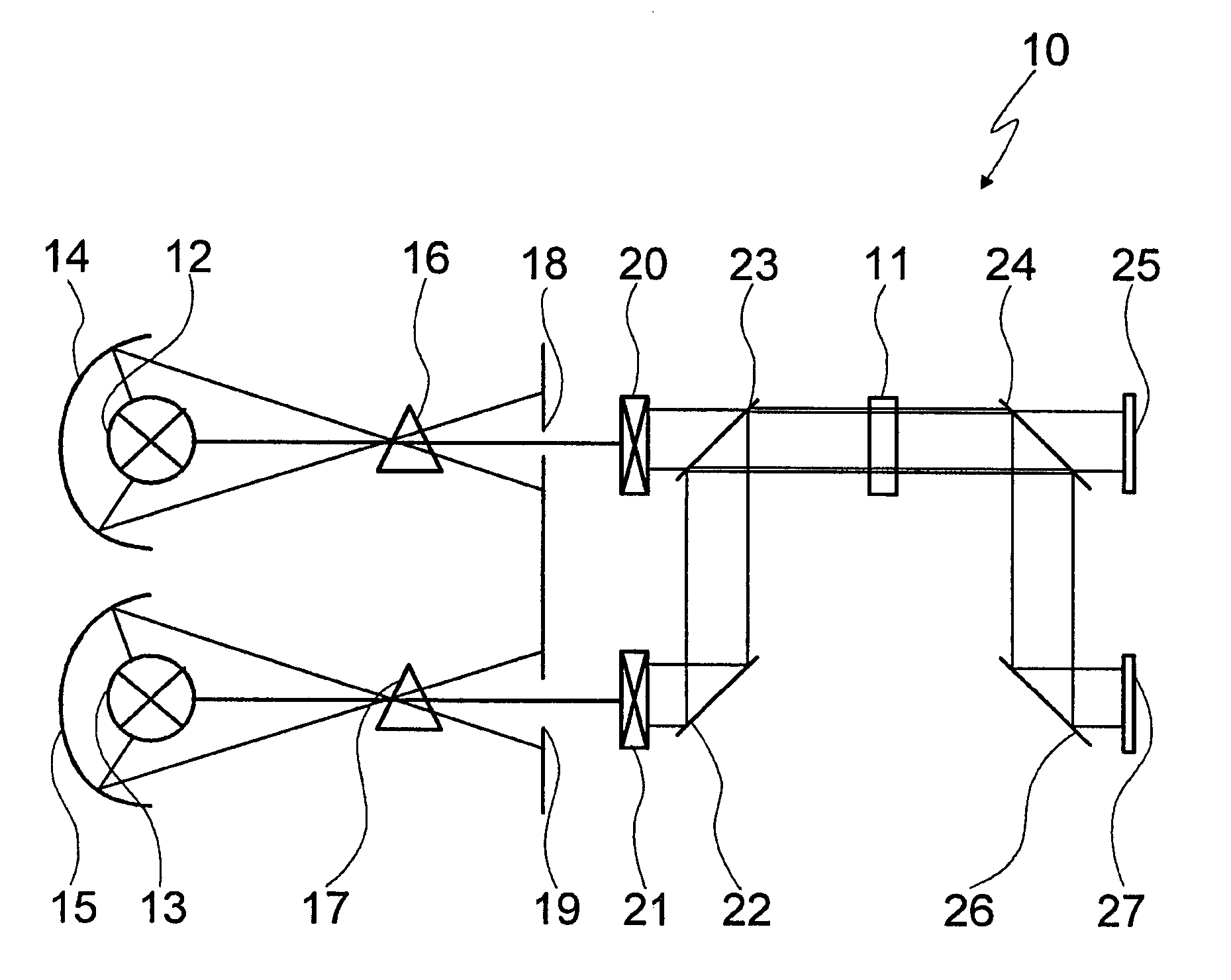

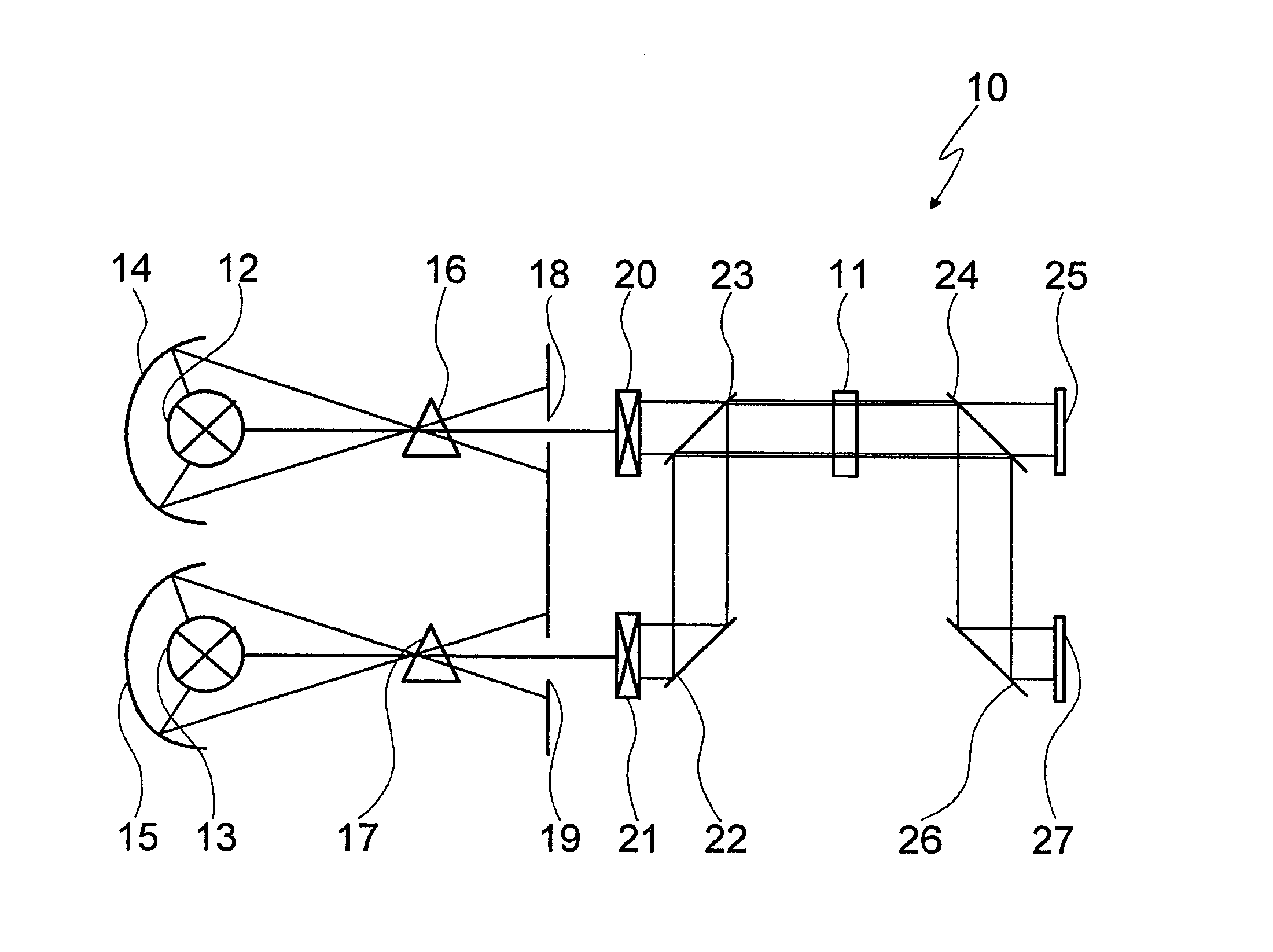

Seamless optical splicing method for 3*3 flat detectors

InactiveCN102928903ANo lossNo loss of field of viewPrismsPicture taking arrangementsAviationOptical axis

The invention discloses a seamless optical splicing method for 3*3 flat detectors. A symmetric prism structure is adopted for image plane light splitting, four flat detectors are arranged on an optical axis perpendicular transmission image plane, and five flat detectors are arranged on four side faces. A few of spliced structures are symmetric, simple and distributed in a centralized way, and energy is not lost after total-reflection total-transmission light splitting. The seamless splicing method can be applied to aviation and aerospace optical imaging, optical detection instruments and equipment and is particularly suitable for aviation and aerospace imaging photoelectric systems of extra-large flat detectors.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

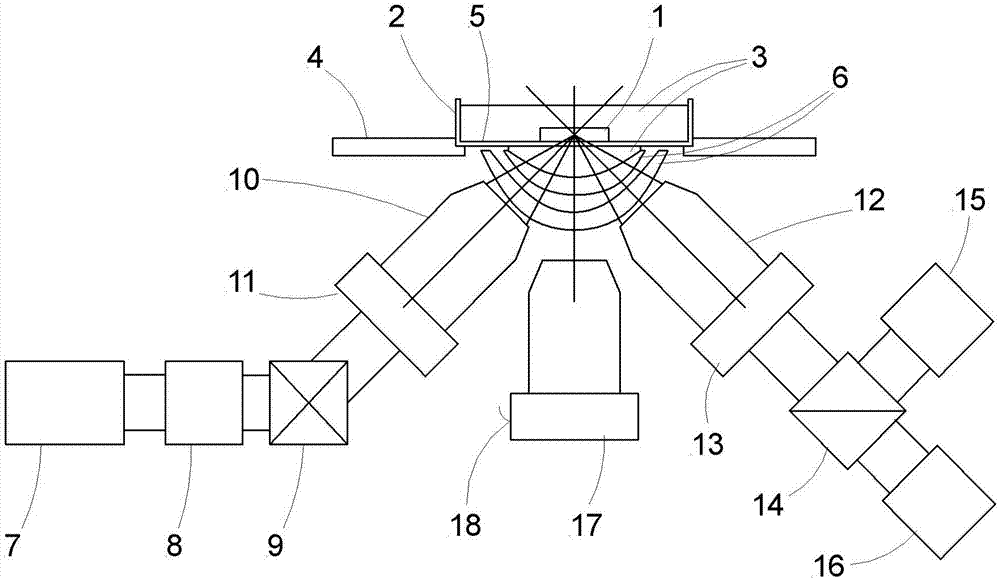

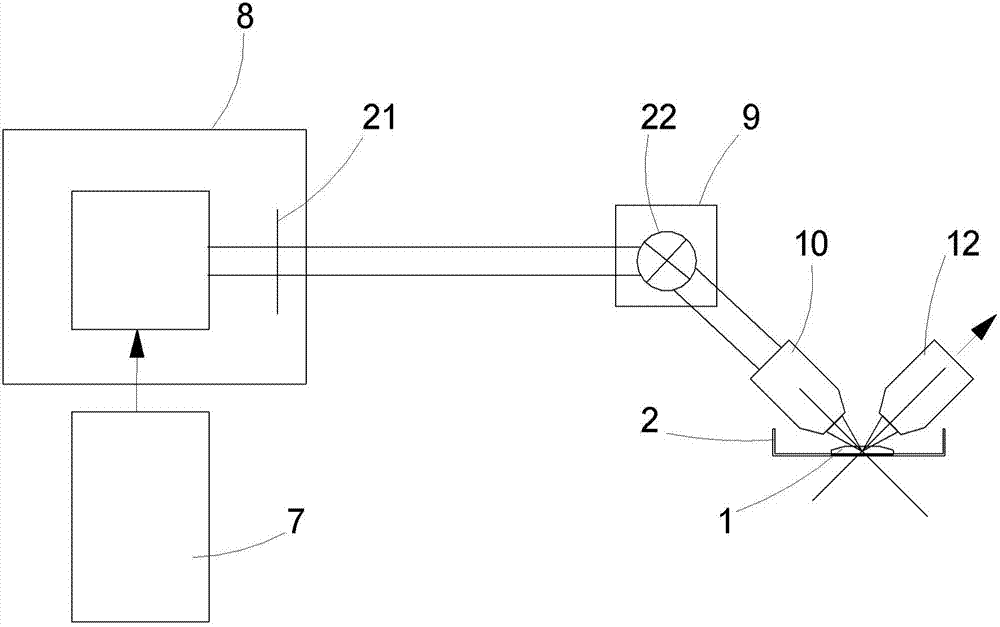

Method and assembly for light sheet microscopic analysis of a sample

The invention relates to a light sheet microscope which comprises an illumination device, which generates coherent illumination light for multiple illumination wavelengths, a beam forming module (8) for generating a light sheet from illumination light, an illumination objective (10) for illuminating a sample (1) with the light sheet, and a detection objective (12) for mapping the light, which is emitted by the sample, onto a flat detector, wherein the optical axis of the detection objective (12) includes an angle which differs by 0 DEG and 180 DEG from the optical axis of the illumination objective (10). In such a light sheet microscope, the beam forming module (8) comprises a phase-selective element (19) on which multiple selection regions (20) are arranged which are spatially separated from one another, wherein each selection region (20) is assigned to a specific illumination wavelength, and wherein a predefined phase distribution for the respective illumination wavelengths is applied to each selection region (20). In addition, the beam forming module (8) comprises means for sequential or simultaneous selection of the selection regions (20) according to the respective illumination wavelengths.

Owner:CARL ZEISS MICROSCOPY GMBH

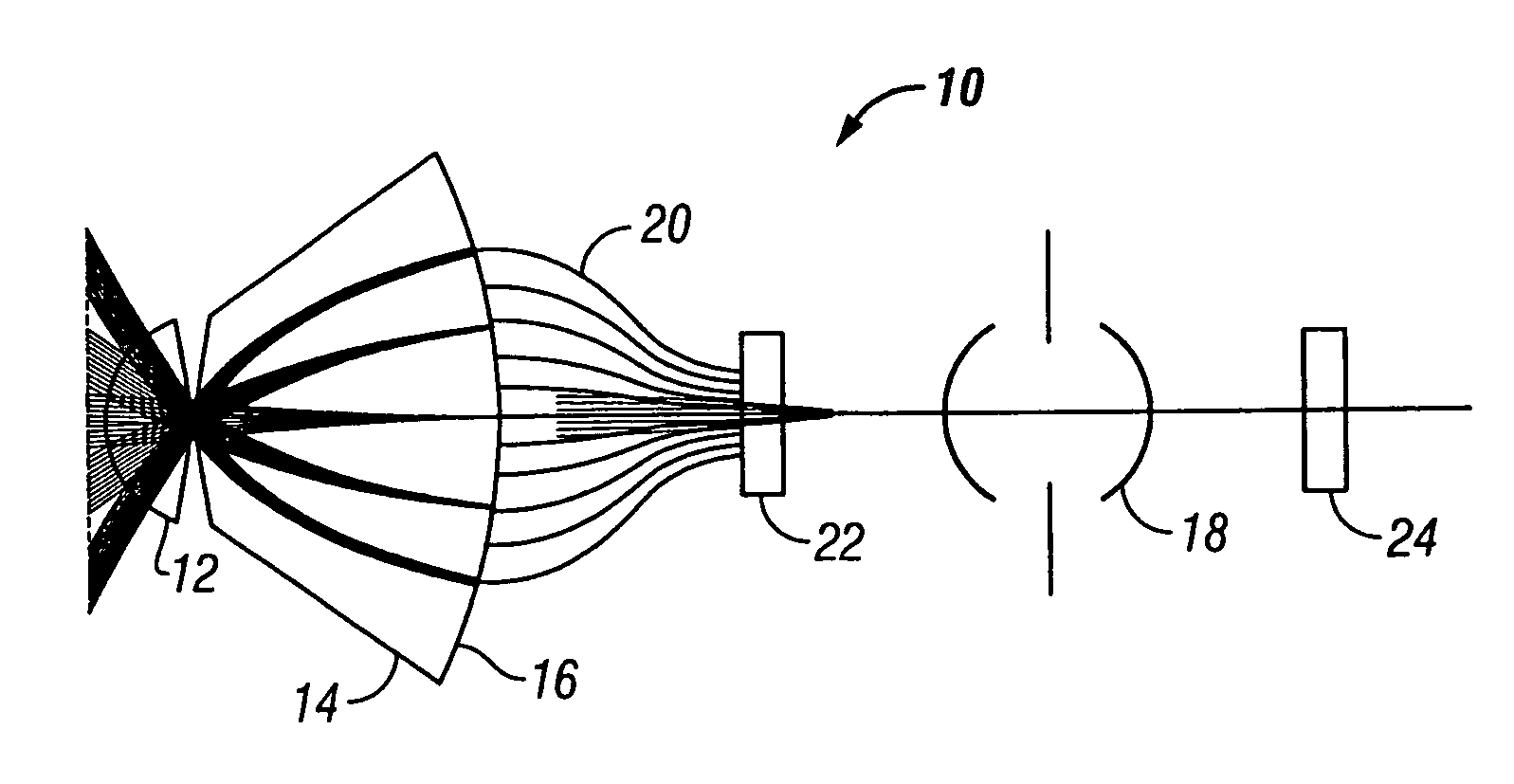

Variable field of view optical system

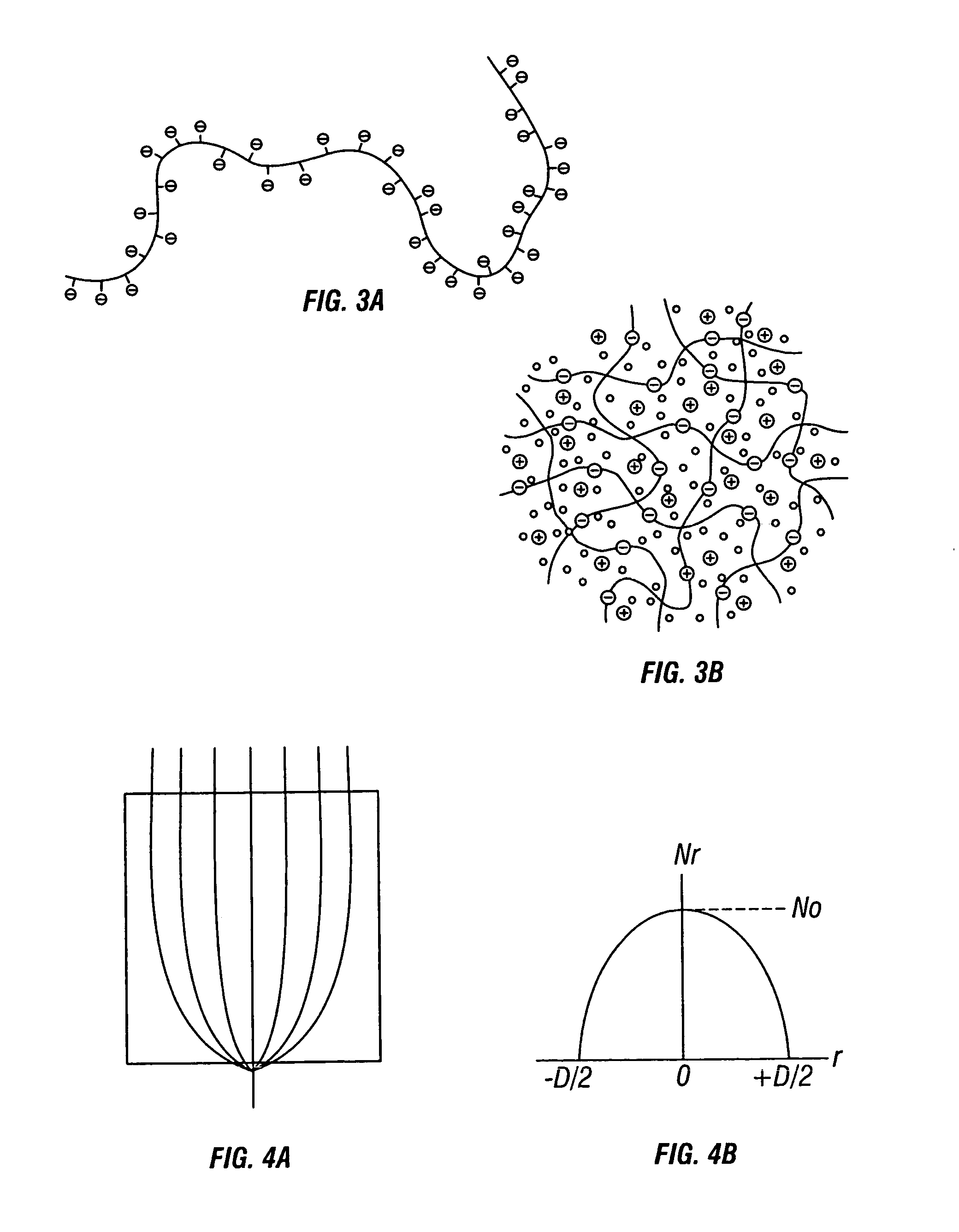

InactiveUS7010202B1Reduce resolutionCoupling light guidesBundled fibre light guideFlat detectorRefractive index

A variable field of view optical system and method comprising providing a forward curved optical element, providing a rearward optical element comprising an axially gradient index material, providing a curved focal surface, and conveying an image on the curved focal surface to a flat detector surface.

Owner:LOCKHEED MARTIN CORP

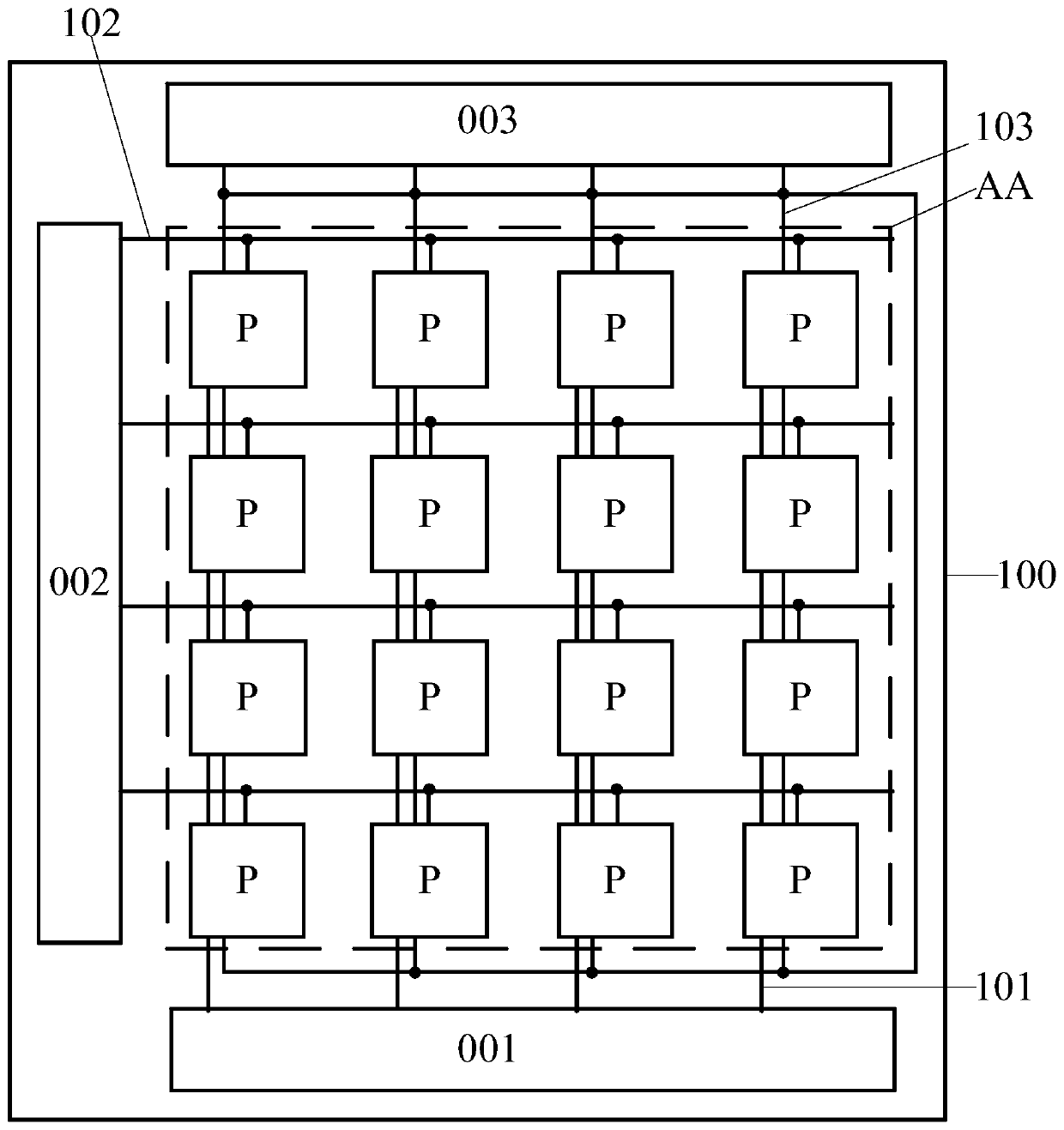

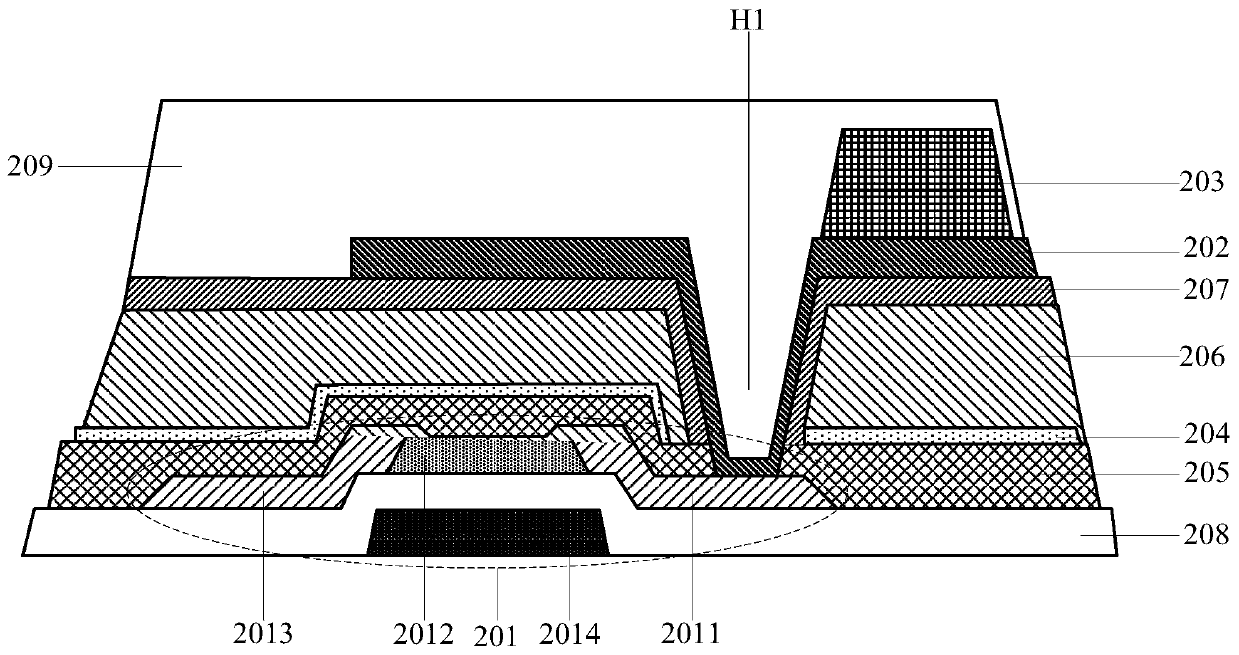

Detection substrate, manufacturing method thereof and flat panel detector

PendingCN111244119AImprove performanceImprove stabilityTransistorSolid-state devicesFlat detectorElectrical connection

The invention discloses a detection substrate, a manufacturing method thereof and a flat panel detector. The detection substrate comprises a substrate body, a plurality of transistors, an oxide layer,a plurality of reading electrodes and a plurality of photoelectric conversion structures, wherein the transistors, the oxide layer, the reading electrodes and the photoelectric conversion structuresare sequentially located on the substrate body; the first electrodes of the transistors are electrically connected with the photoelectric conversion structures in a one-to-one correspondence manner through the reading electrodes, and the material of an active layer comprises an oxide; and each photoelectric conversion structure comprises an N-type semiconductor layer, an intrinsic semiconductor layer and a P-type semiconductor layer. The oxide layer at least covers the channel regions of the transistors and is insulated from the reading electrodes. The oxide layer covering the channel regionsof the transistors is arranged between the layer where each transistor is located and the layer where each reading electrode is located, so hydrogen atoms generated in the subsequent process of depositing the photoelectric conversion structure react with the oxide layer, the hydrogen atoms are prevented from reaching the channel region, the stability of the transistor is effectively improved, andthe performance of the flat panel detector is improved.

Owner:BOE TECH GRP CO LTD +1

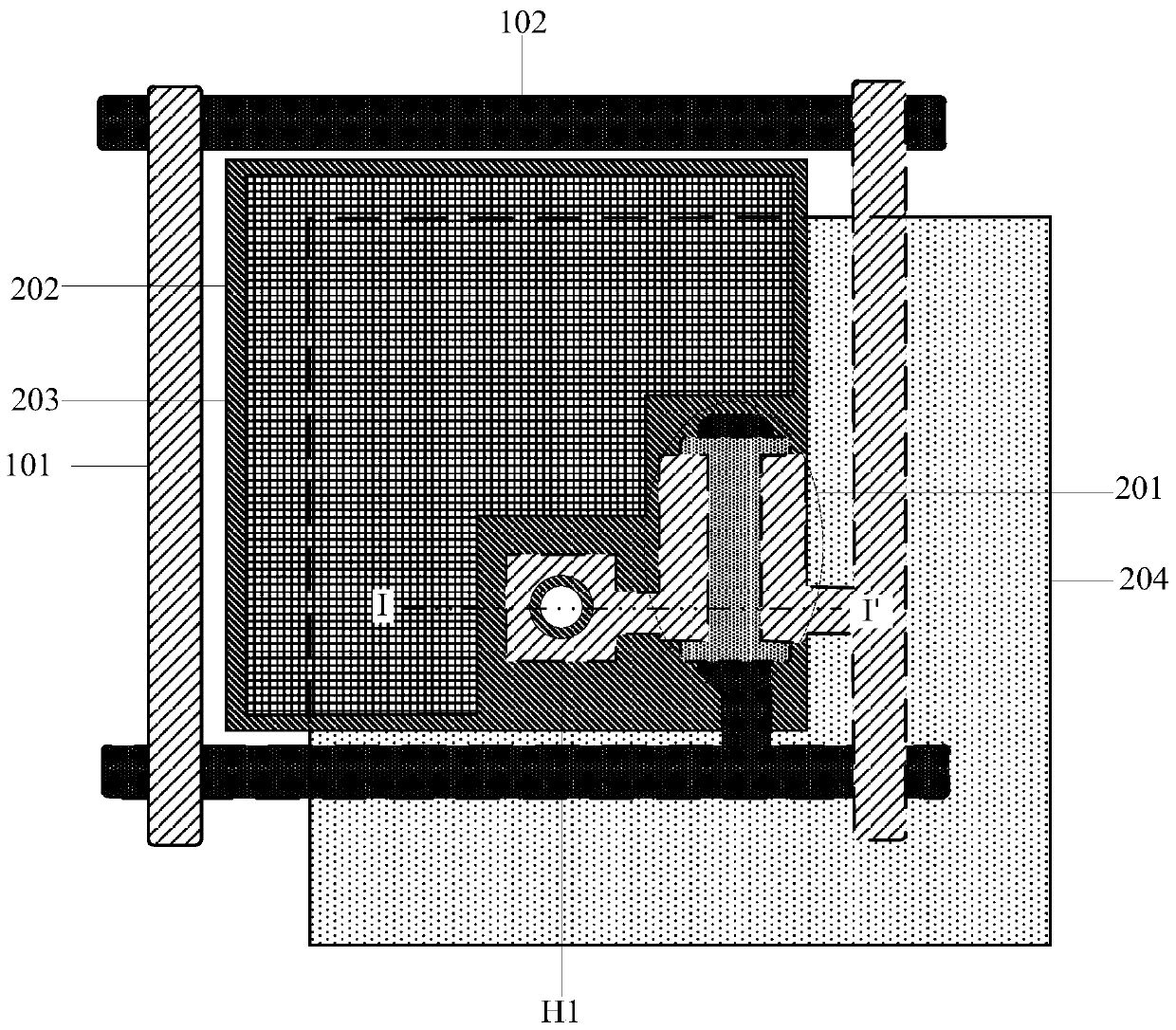

Flat panel detector and manufacturing method thereof

The invention provides a flat panel detector and a manufacturing method thereof. The flat panel detector comprises a TFT device with a semiconductor layer, a first insulating layer covering the TFT device, an interlayer insulating layer on the first insulating layer, a cathode electrode which is located on the interlayer insulating layer and connected with the TFT device, and a photoelectric conversion layer located on the cathode electrode. The flat panel detector further comprises a barrier layer on the interlayer insulating layer. At least part of the barrier layer is in a floating state, and at least part of the barrier layer is located directly above the semiconductor layer. According to the invention, the barrier layer is arranged on the flat panel detector; at least part of the barrier layer is located directly above the semiconductor layer; and the barrier layer can block the influence of hydrogen diffusion on the semiconductor layer when the photoelectric conversion layer is formed, and can block the influence of X-ray or ambient light on the semiconductor layer.

Owner:NANJING DETECH FUTURE TECH CO LTD

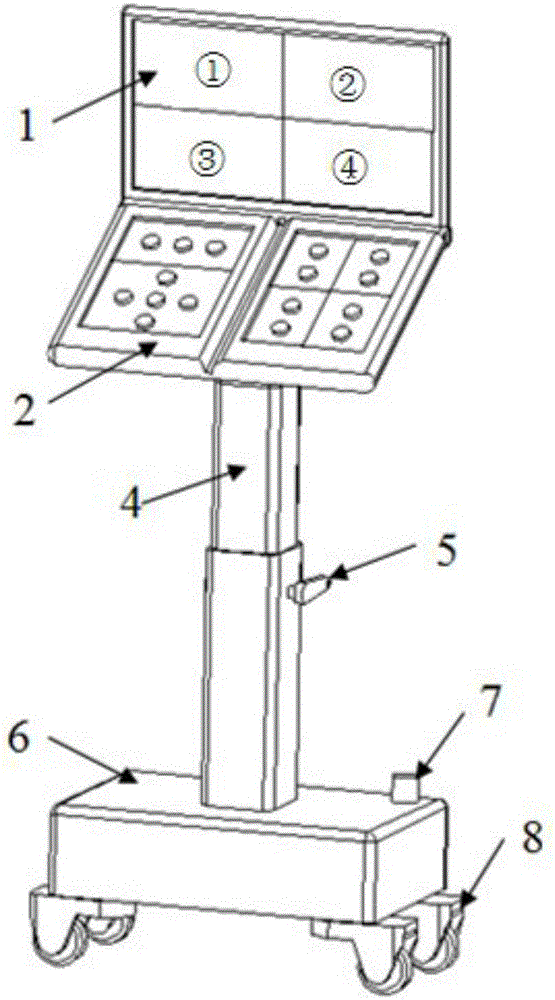

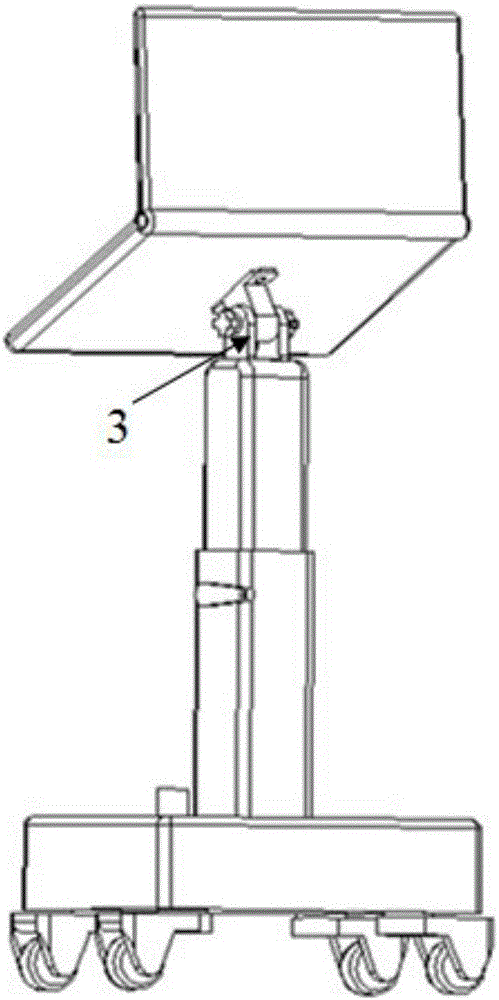

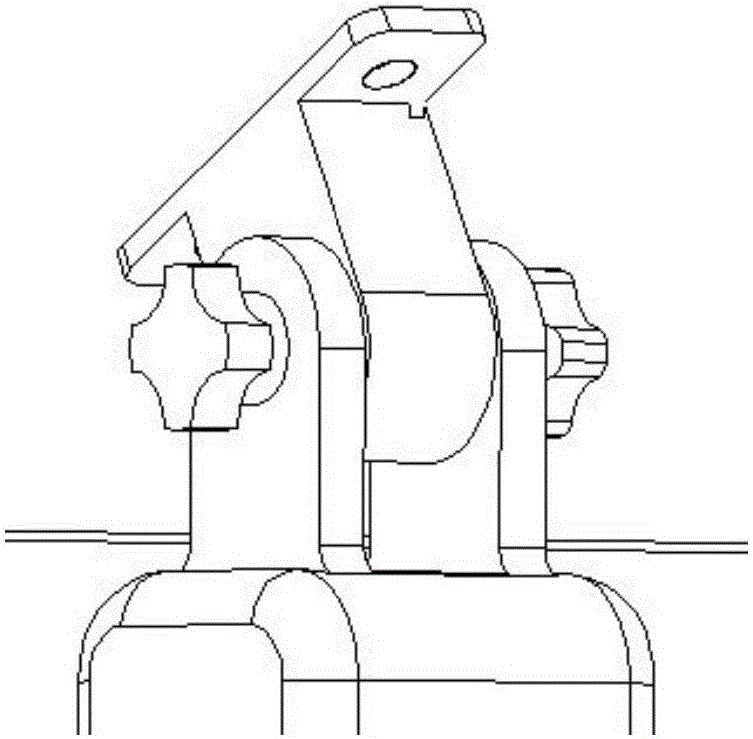

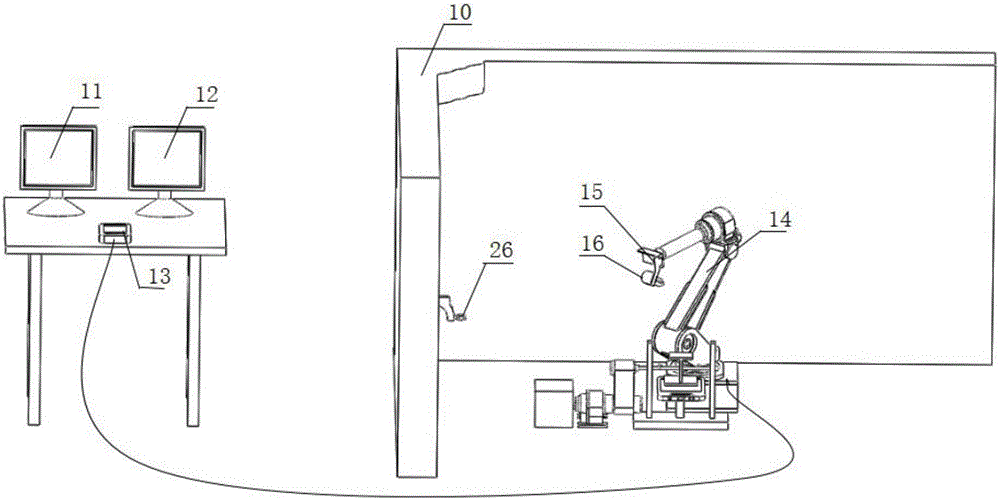

X-ray nondestructive inspection integral remote control platform for electric equipment

InactiveCN105136826AEasy to moveImprove NDT EfficiencyMaterial analysis by transmitting radiationRemote controlX-ray

The invention relates to an X-ray nondestructive inspection integral remote control platform for electric equipment. The X-ray nondestructive inspection integral remote control platform is characterized by comprising a display screen (1), a control table (2), a telescopic support post (4), an angle regulator (3) and a regulating handle (5), wherein the telescopic support post (4) is fixedly arranged on a moving trolley (6) provided with universal wheels (8); a signal antenna (7) is arranged on the moving trolley (6); a power supply and a central processing unit are arranged in a trolley body of the moving trolley (6). The X-ray nondestructive inspection integral remote control platform has the beneficial effects that the imaging result display of a flat detector and the regulation and control of a vehicle-mounted platform are integrated onto one integral remote control platform in a unified way; detection equipment can be remotely and automatically regulated and controlled in time according to the imaging result; operators can complete all work without walking to and fro; the use complexity is greatly reduced; the X-ray nondestructive inspection efficiency is improved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

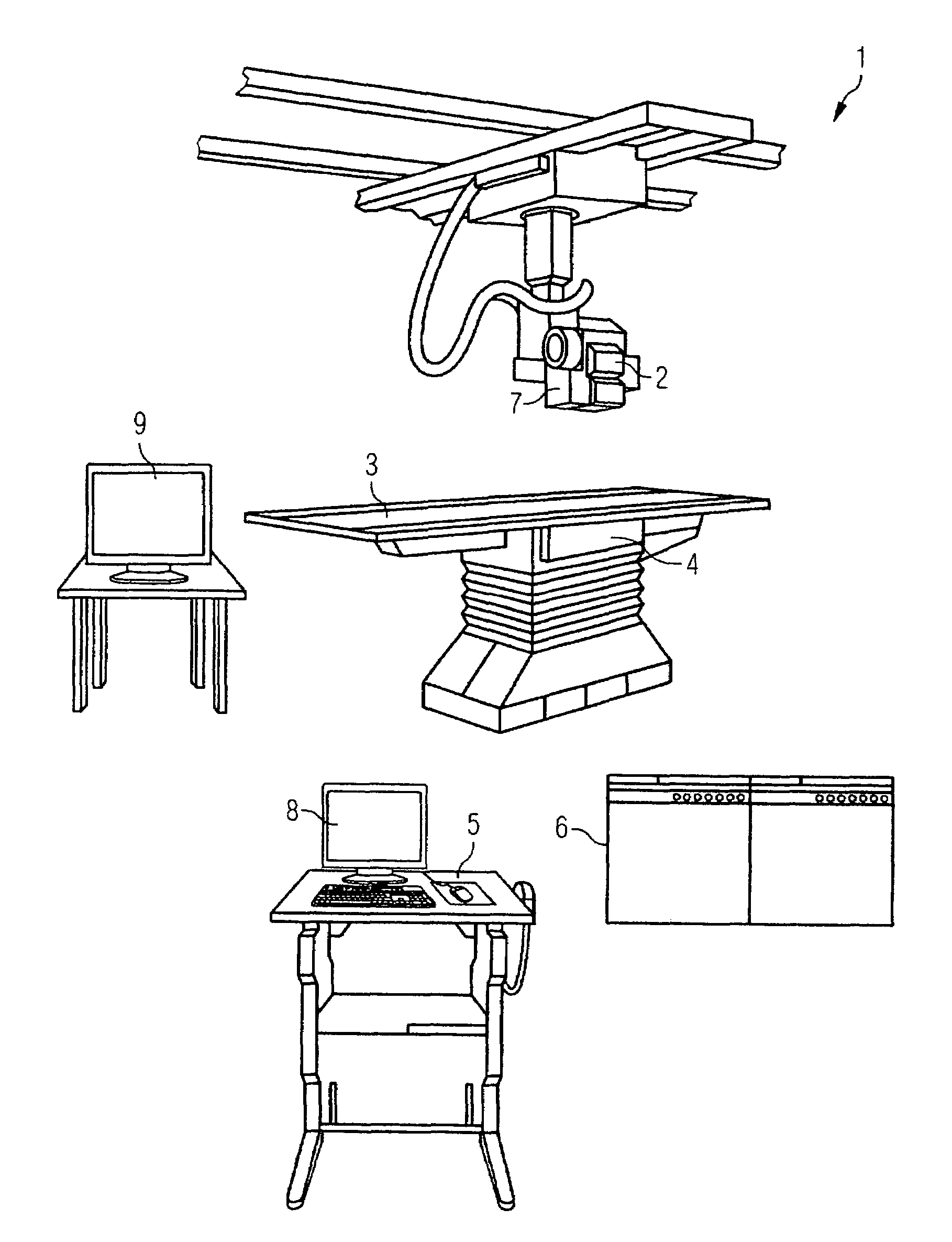

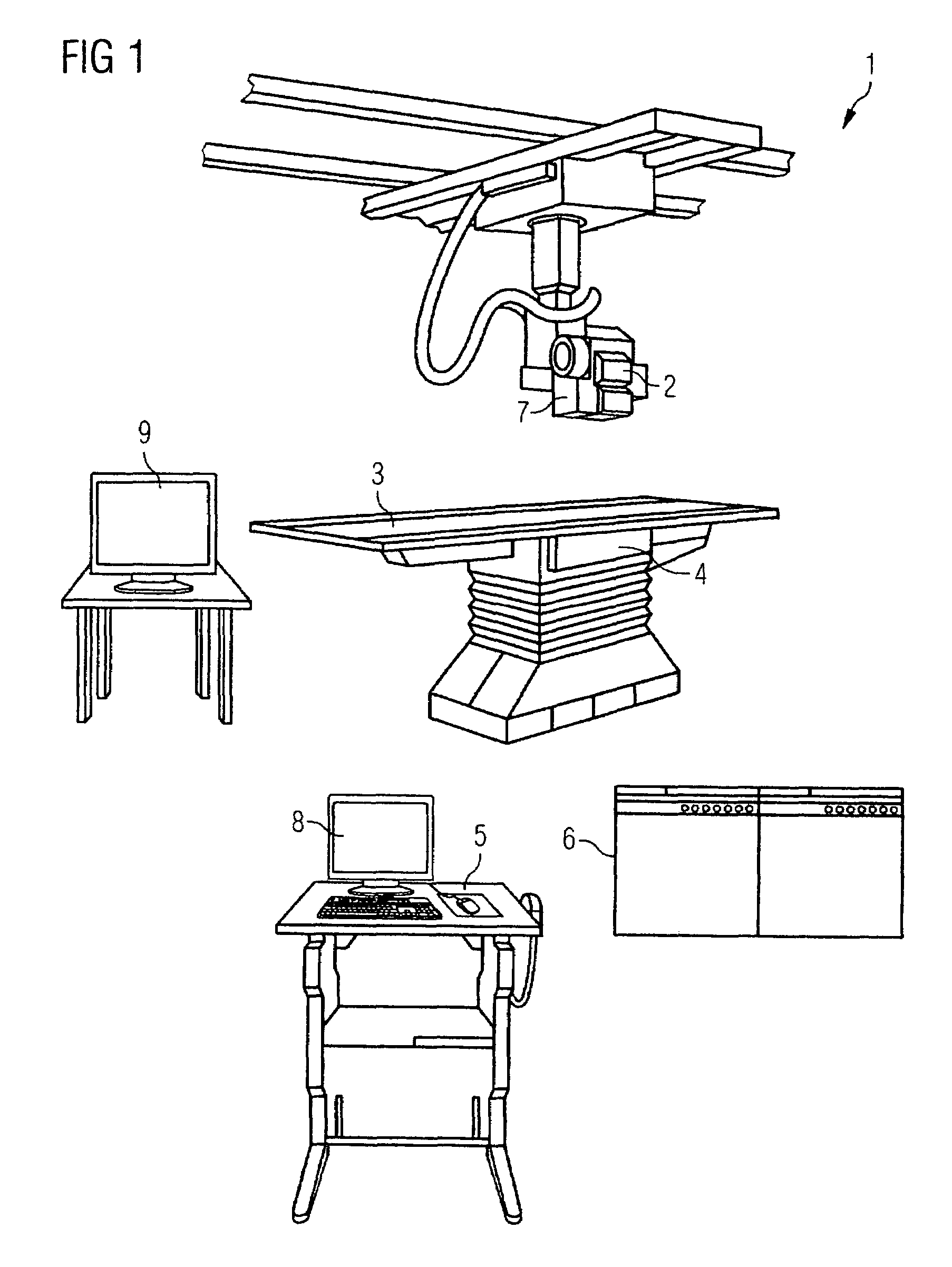

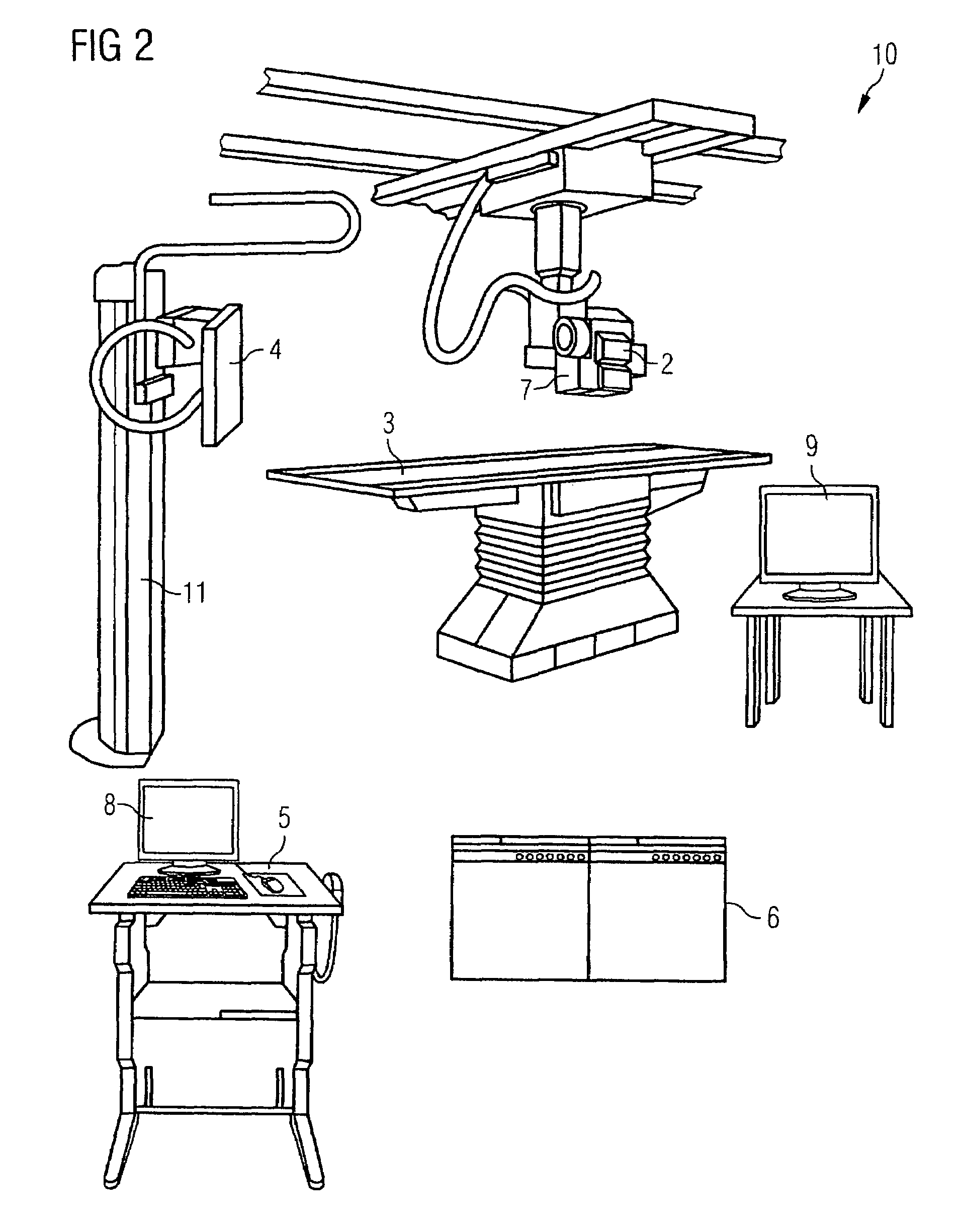

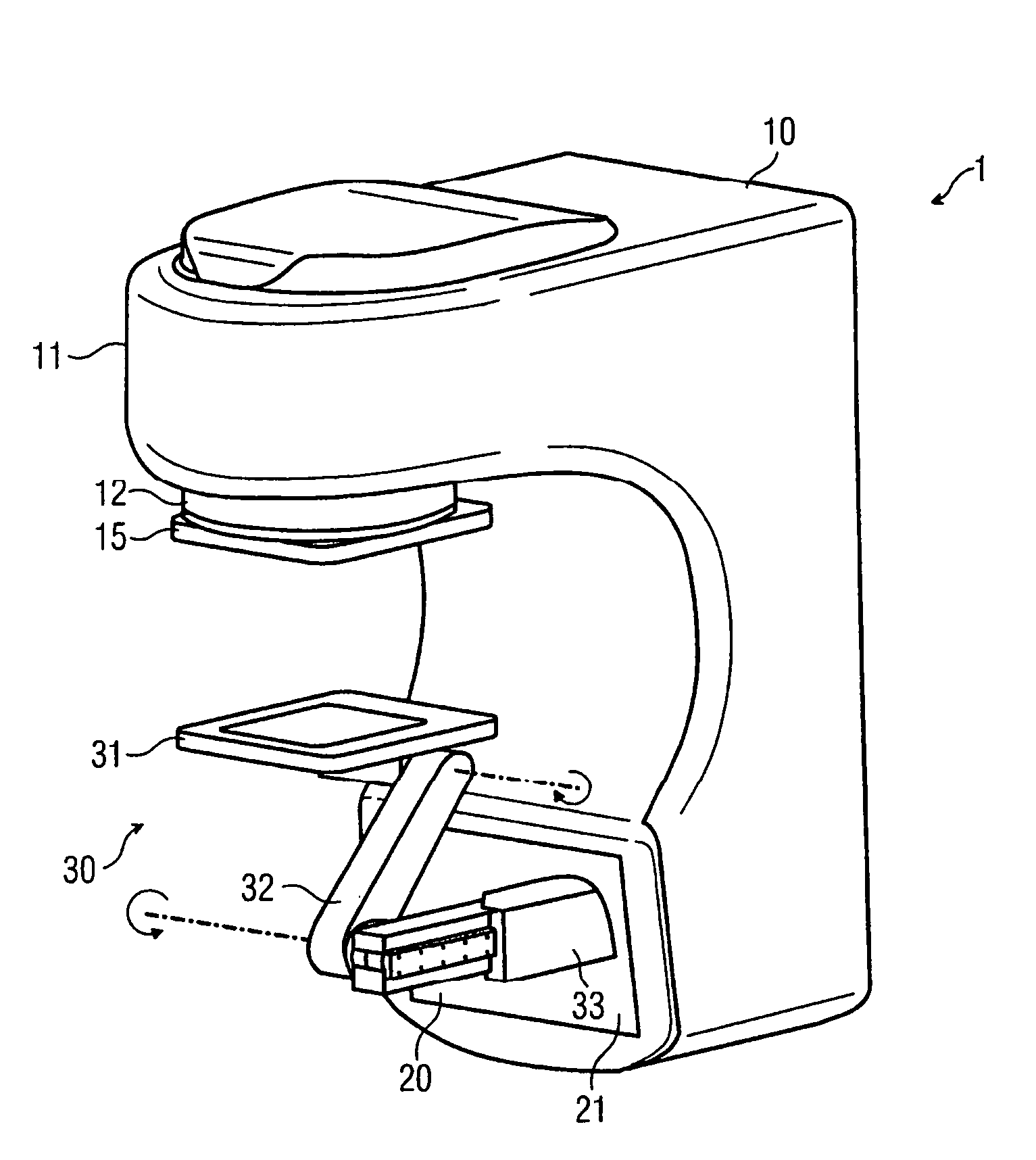

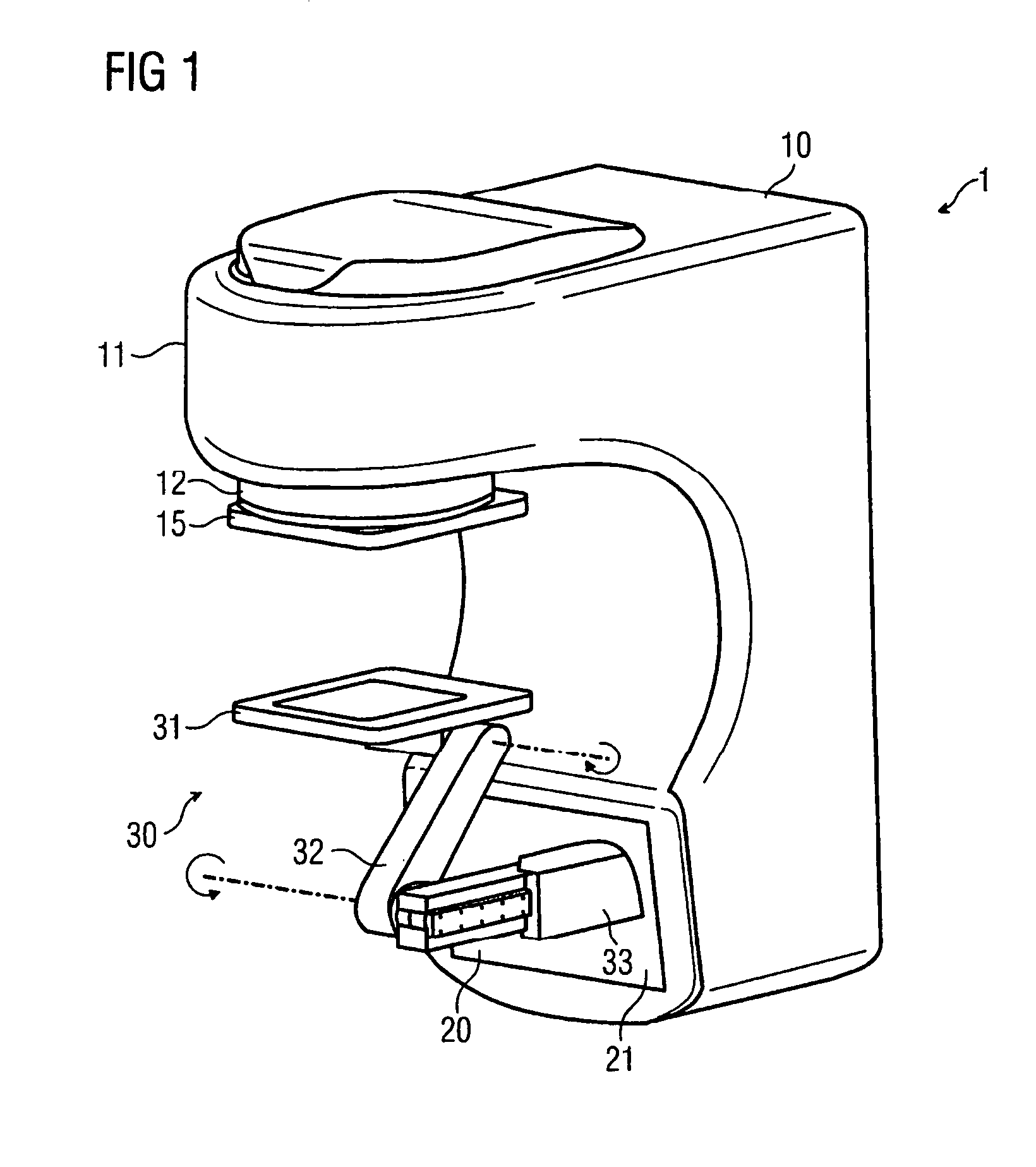

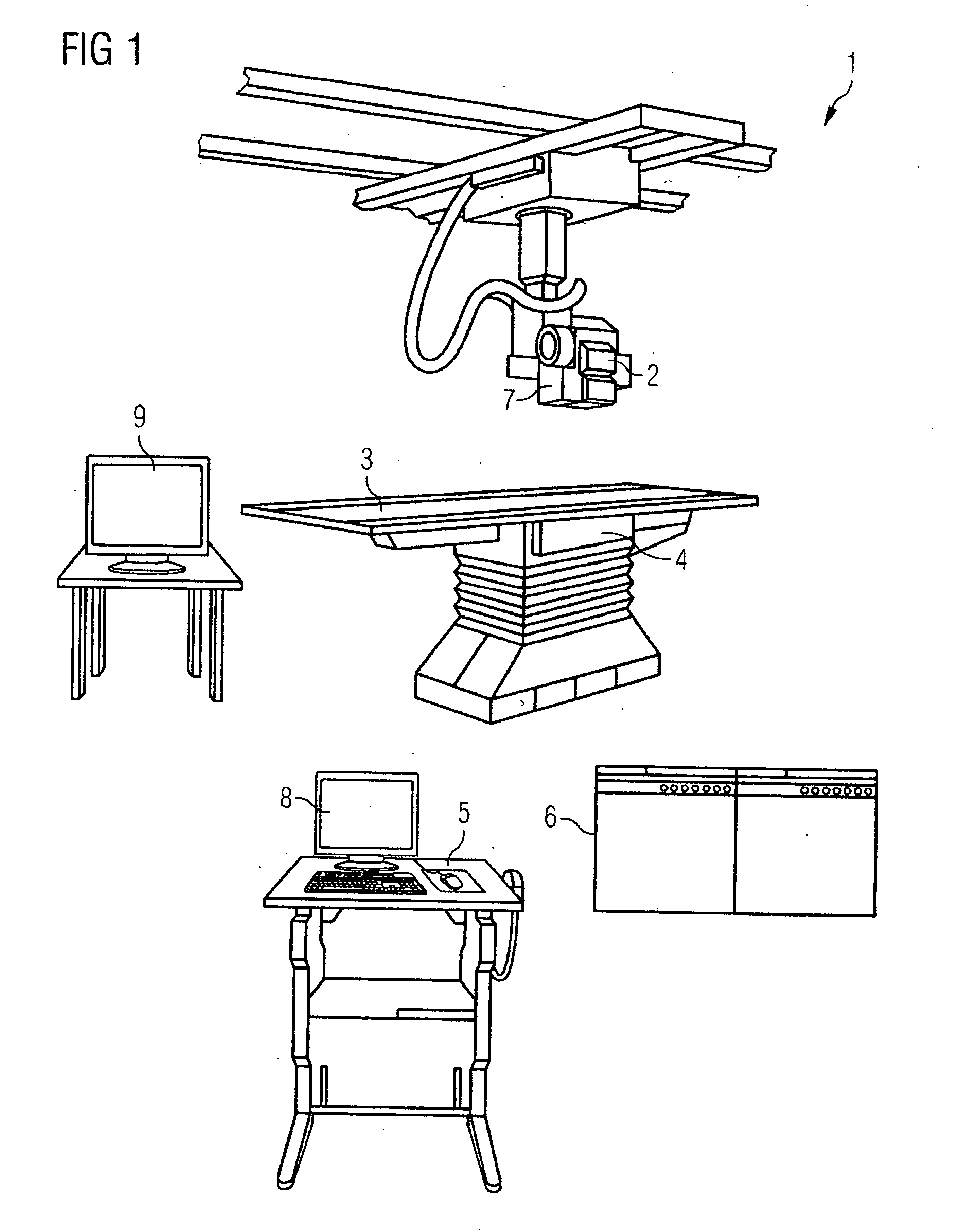

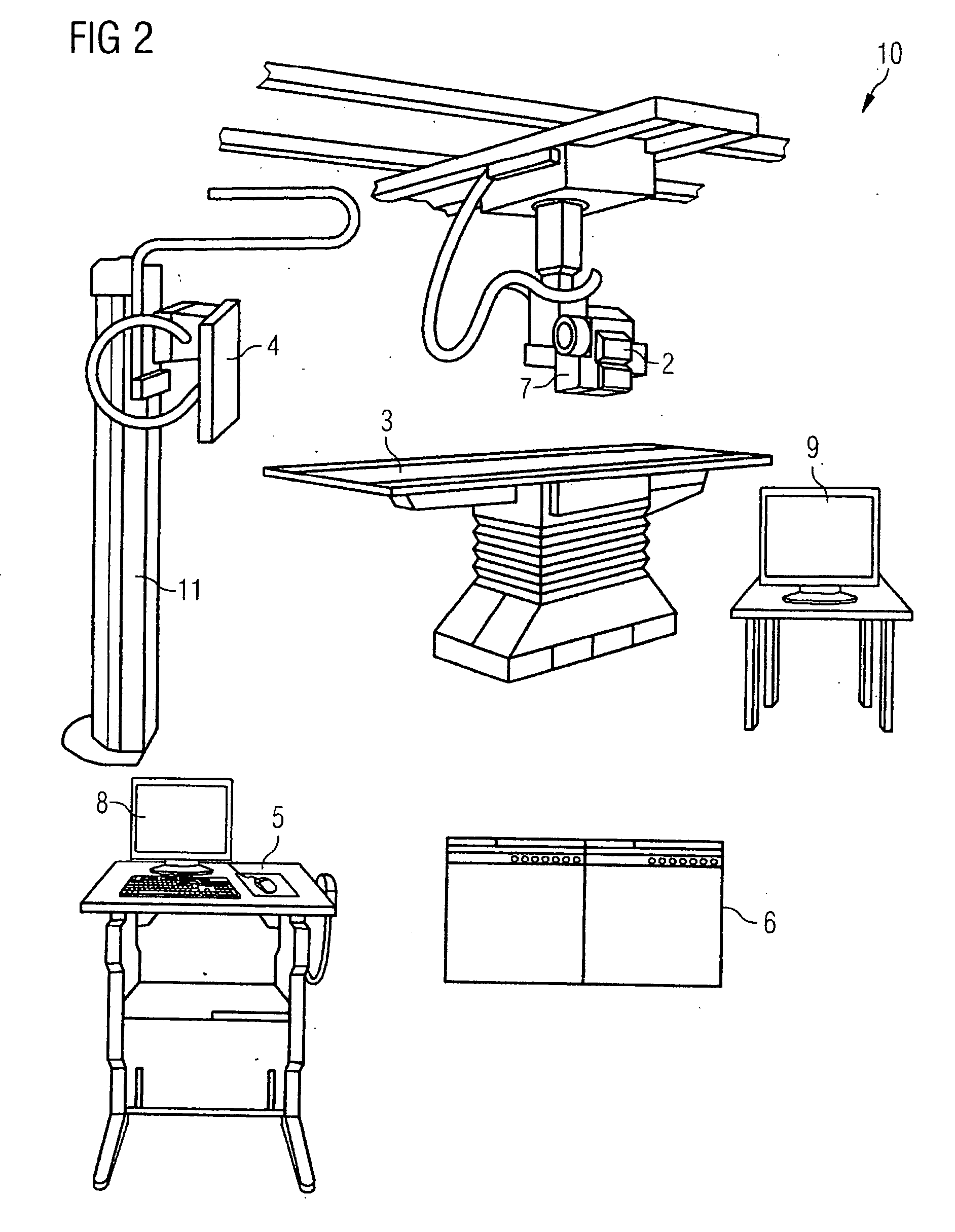

Radiography device for recording dynamic processes and associated recording method

ActiveUS7596206B2Reduce loadReduce radiation loadRadiation/particle handlingX-ray apparatusIntervention measuresFlat detector

There is described a radiography device for recording dynamic processes and an associated recording method. The radiography arrangement is used to examine patients using an x-ray source, a digital flat detector with a single shot recording function and an operating console for controlling and recording purposes, with the flat detector also being able to display an image sequence at a rate of up to 5 Hertz, which allows the positioning of the region to be examined or the monitoring of pseudo-interventional interventions.

Owner:SIEMENS HEALTHCARE GMBH

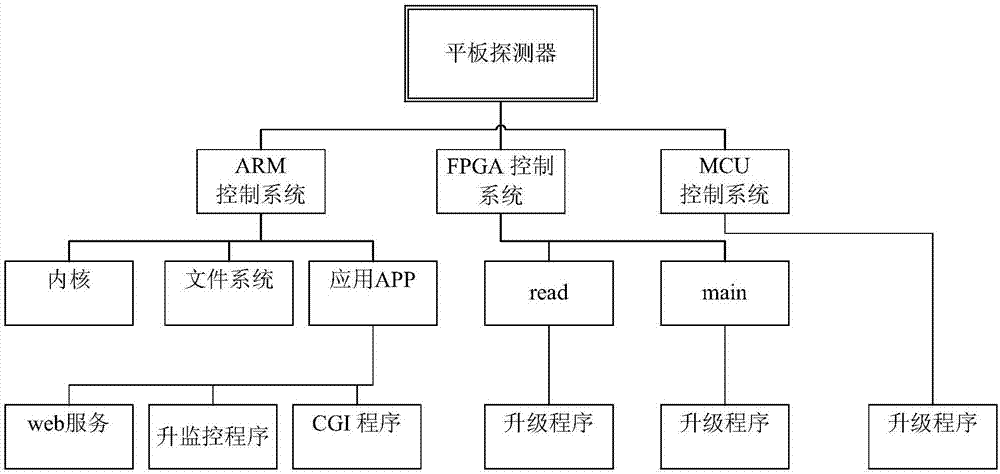

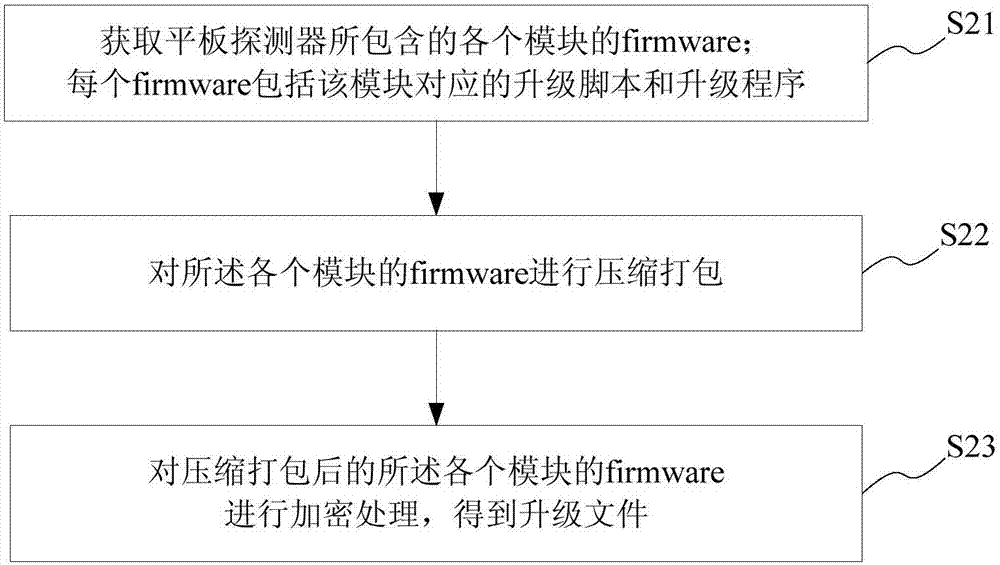

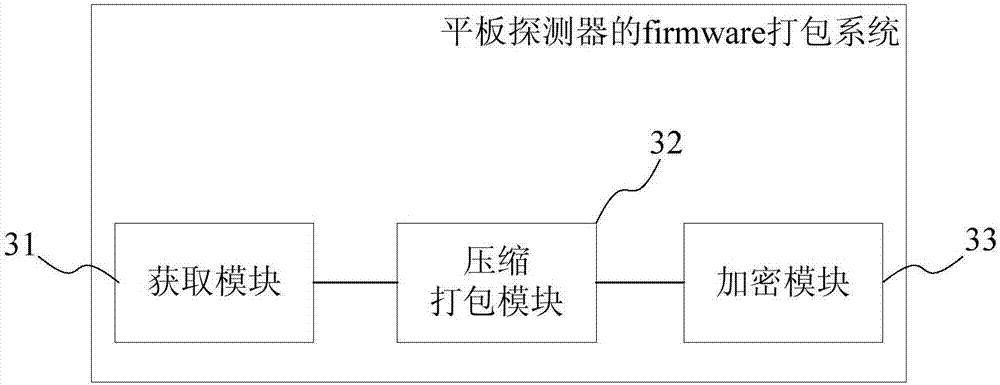

Firmware packaging method and system of flat panel detector, firmware upgrading method and system of flat panel detector, storage medium and flat panel detector

InactiveCN107885519ACumbersome connectivityCumbersome selectivitySoftware deploymentFlat panel detectorTerminal equipment

The invention provides a firmware packaging method and system of a flat panel detector, a firmware upgrading method and system of the flat panel detector, a storage medium and the flat panel detector.The firmware upgrading method comprises the following steps of: obtaining an upgrading file sent by terminal equipment; decrypting and decompressing the upgrading file; and upgrading each module of the flat panel detector in sequence according to the decrypted and decompressed upgrading file. According to the firmware packaging method and system, the firmware upgrading method and system, the storage medium and the flat panel detector, uniform packaging and uniform upgrading of firmware of different modules in the flat panel detector can be realized, and extra application programs do not needto be installed, so that the operation is simple and the user experience is greatly enhanced.

Owner:SHANGHAI IRAY TECH

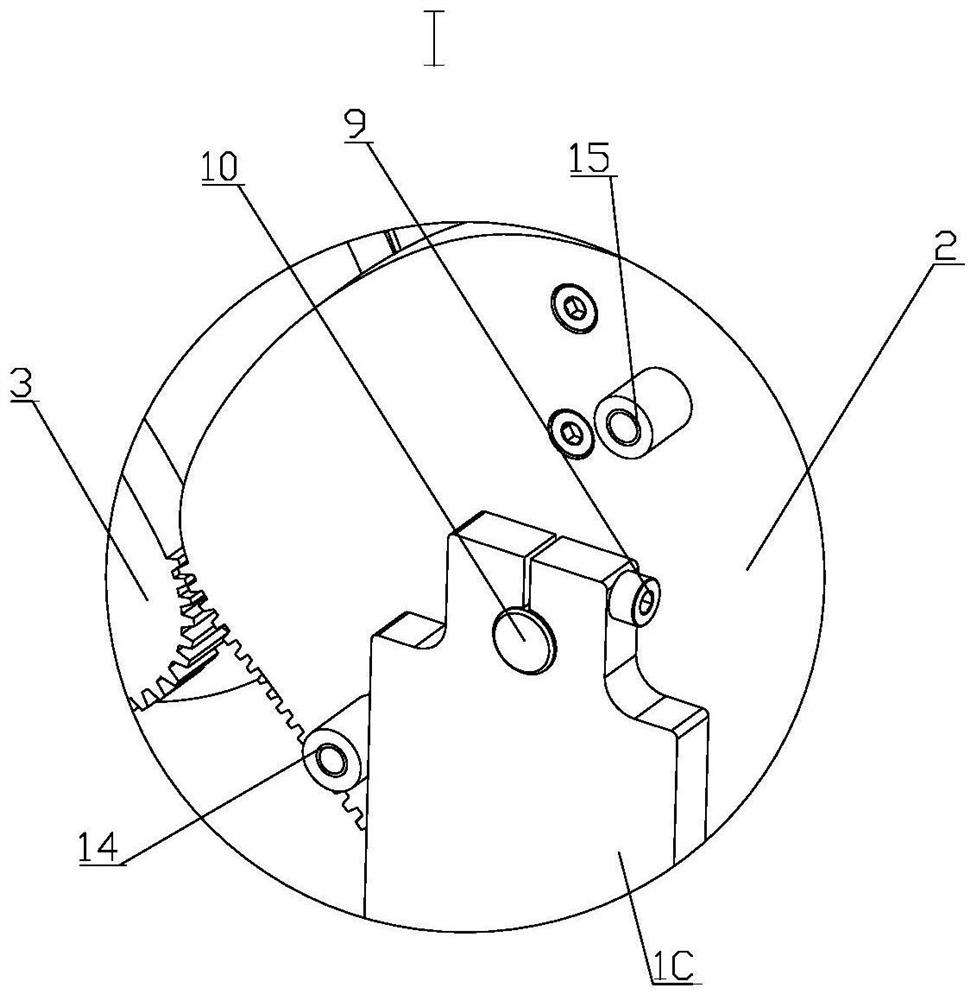

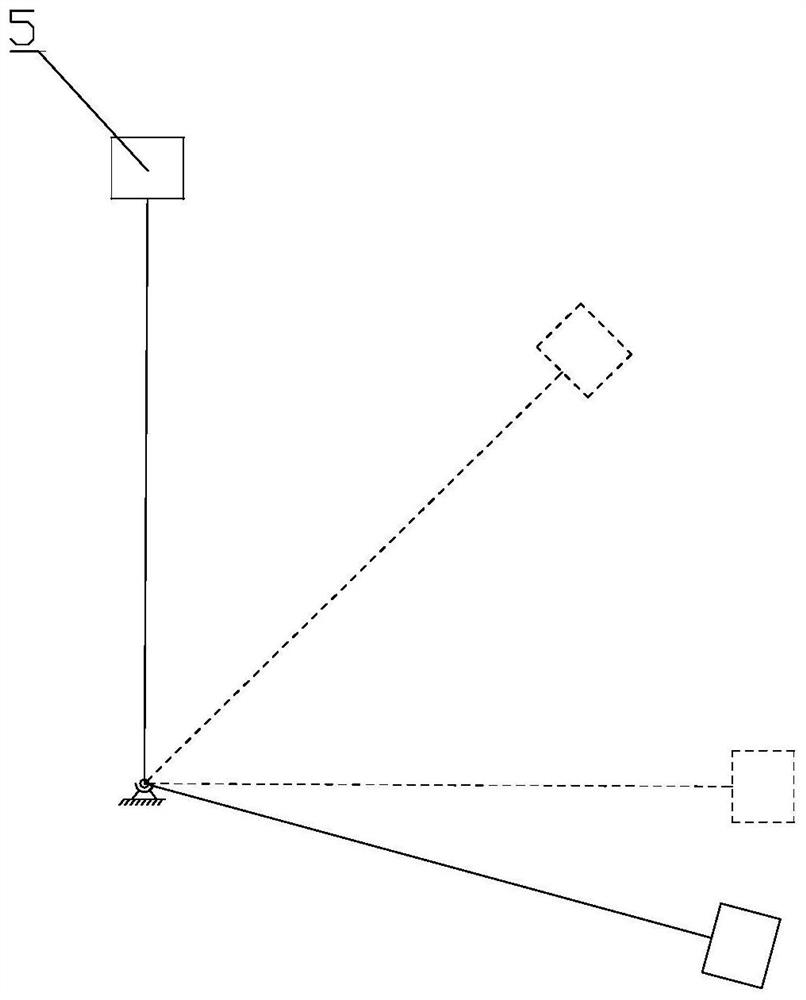

Moment balancer

The invention discloses a moment balancer. The moment balancer comprises a driven gear, a driving gear, a load and an energy storage device, wherein the driven gear and the driving gear are engaged with each other, the load is connected with the driven gear and rotates around the center of the driven gear, and the energy storage device is connected with the driving gear and provides torque for thedriving gear. Due to the fact that the driving gear and the driven gear are set to be in variable-transmission-ratio movement, the pitch line radiuses of the two gears at the instantaneous engaging position are continuously changed, so that the torque generated by the energy storage device on the driven gear through the driving gear and the torque generated by the load gravity adapt to each otherand counteract each other , the load can stably operate during rotation, and accordingly a device provided with the load, for example, an X-ray machine loaded with a flat panel detector operates stably.

Owner:成都开图医疗系统科技有限公司

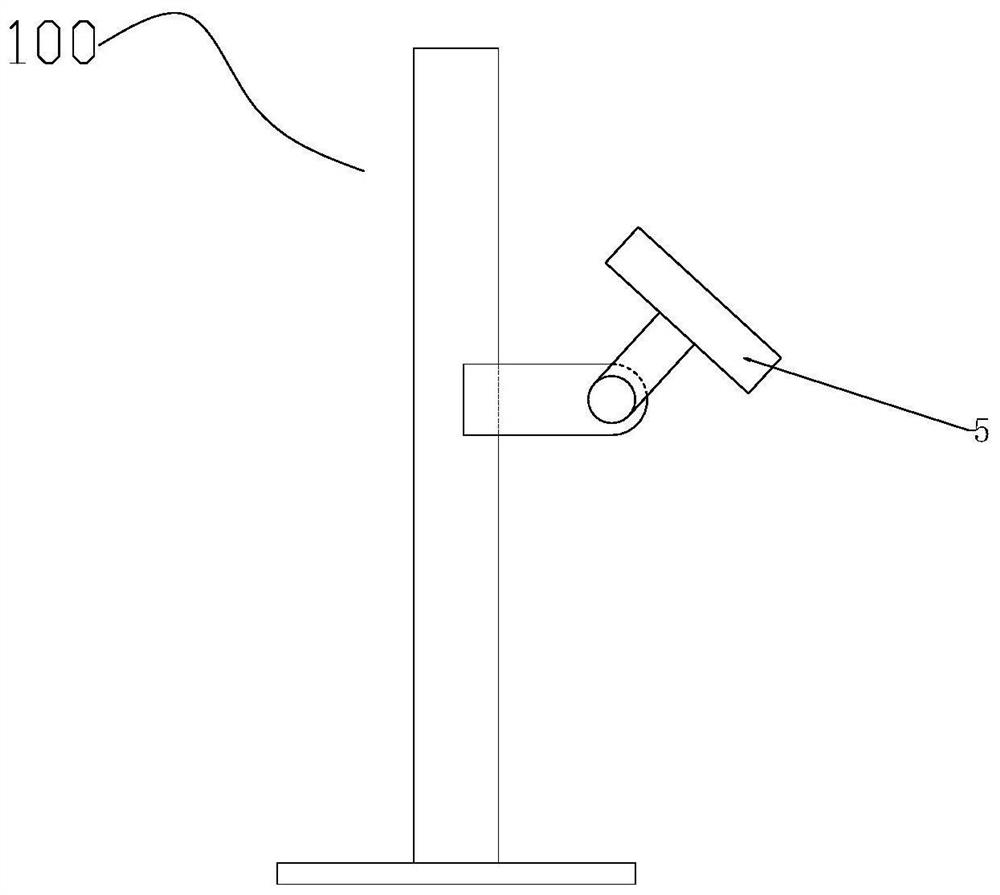

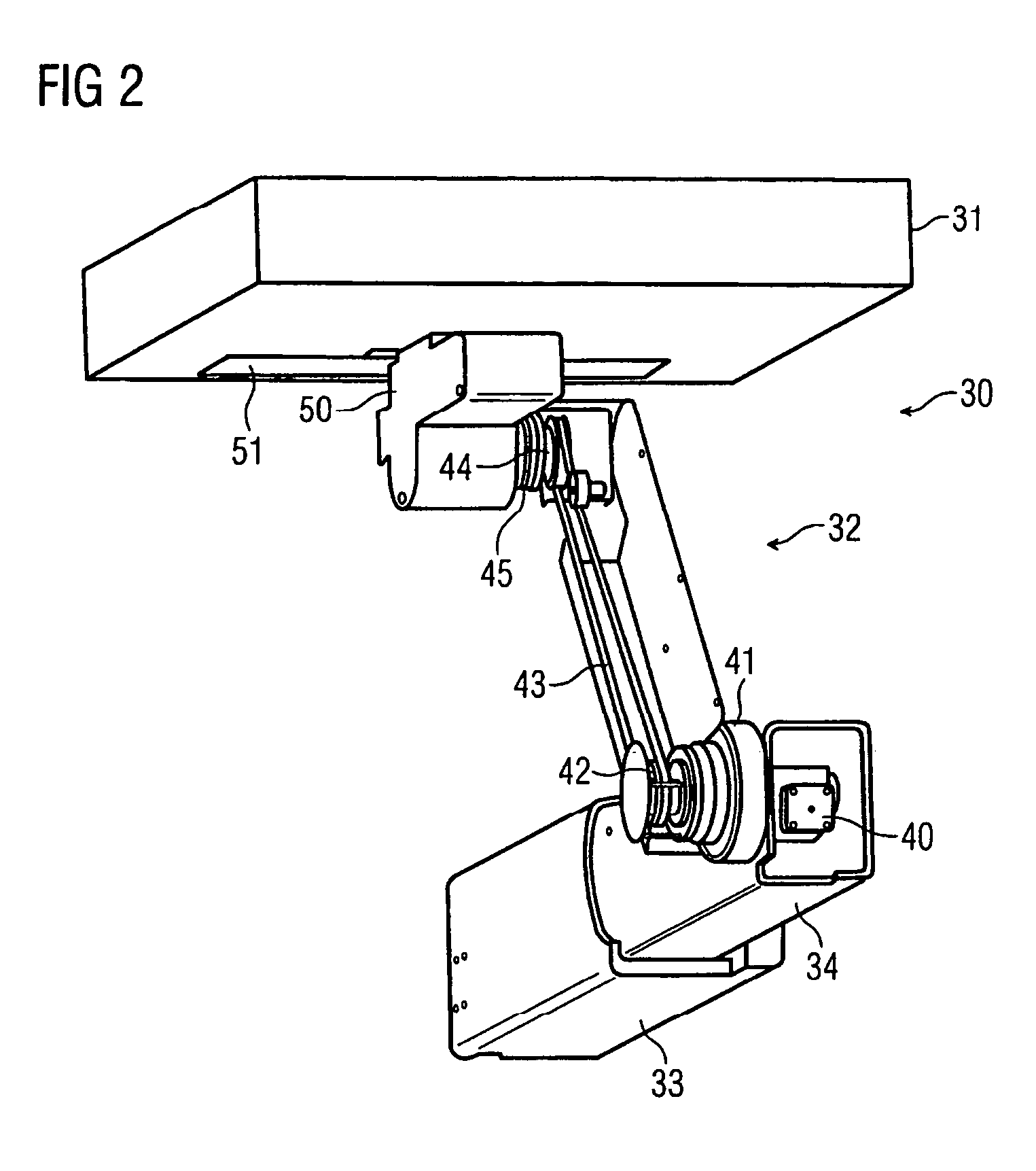

Support and radiation therapy system

InactiveUS7418080B2Improve accuracyAccurate guidanceStands/trestlesImage-conversion/image-amplification tubesFlat detectorEngineering

A support and radiation therapy system is provided. The support includes an elongated support arm that is longitudinally adjustable. A first arm is rotatable in the support arm about a first axis that is perpendicular to the support arm. A flat detector is rotatable in the first arm about a second axis that is parallel to the first axis. The detector is essentially parallel to the support arm. A motor is operative to drive the rotation of the first arm. A first gear is operative to rotate the first arm and is connected to the motor. A second gear is operative to rotate the detector and is connected to the motor. The second gear is operative to rotate contrary to the first gear.

Owner:SIEMENS HEALTHCARE GMBH

Seamless optical splicing method for 3*3 flat detectors

InactiveCN102928903BNo lossNo loss of field of viewPrismsPicture taking arrangementsAviationOptical axis

The invention discloses a seamless optical splicing method for 3*3 flat detectors. A symmetric prism structure is adopted for image plane light splitting, four flat detectors are arranged on an optical axis perpendicular transmission image plane, and five flat detectors are arranged on four side faces. A few of spliced structures are symmetric, simple and distributed in a centralized way, and energy is not lost after total-reflection total-transmission light splitting. The seamless splicing method can be applied to aviation and aerospace optical imaging, optical detection instruments and equipment and is particularly suitable for aviation and aerospace imaging photoelectric systems of extra-large flat detectors.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

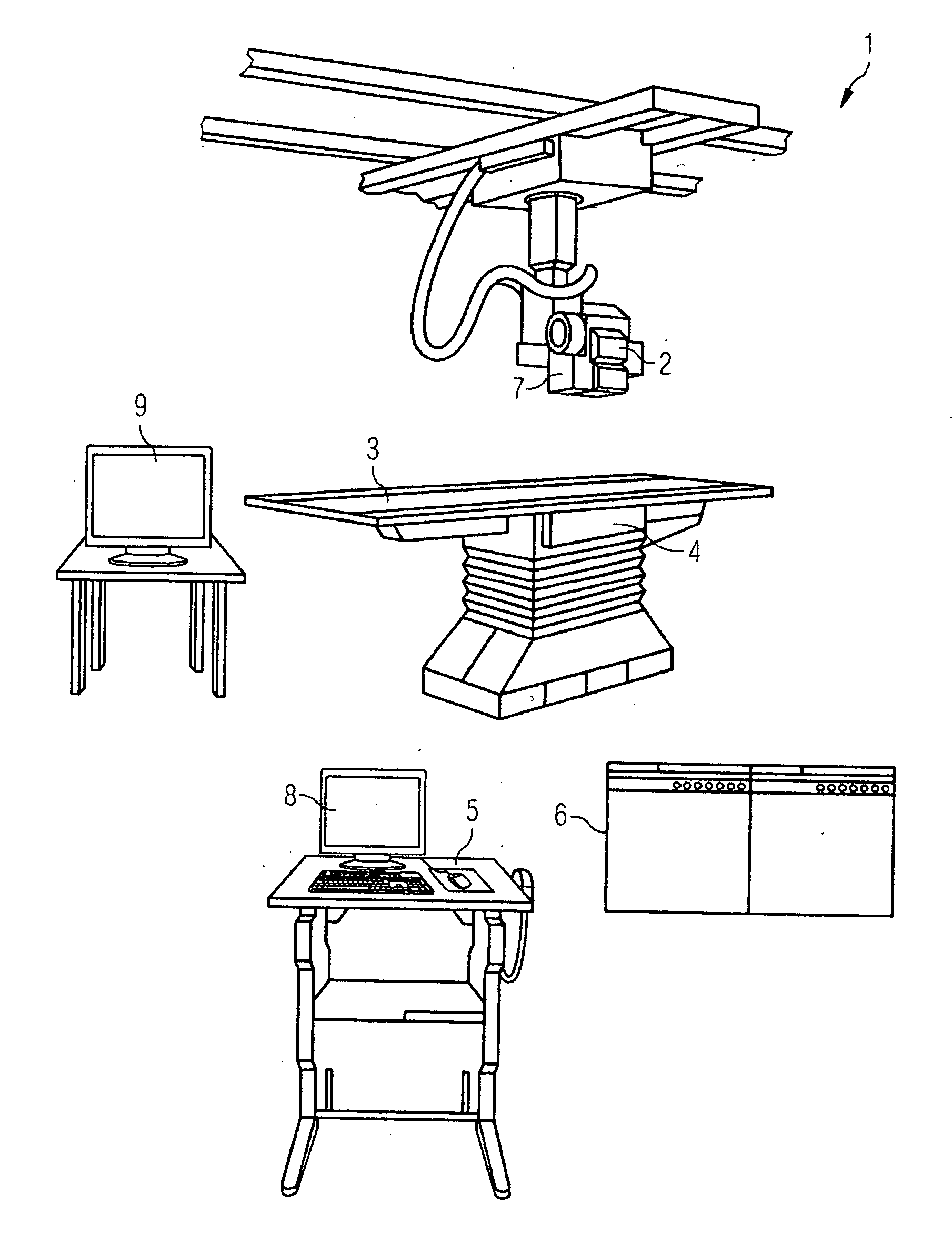

Flat panel X-ray imaging device—twin flat detector signal synchronization

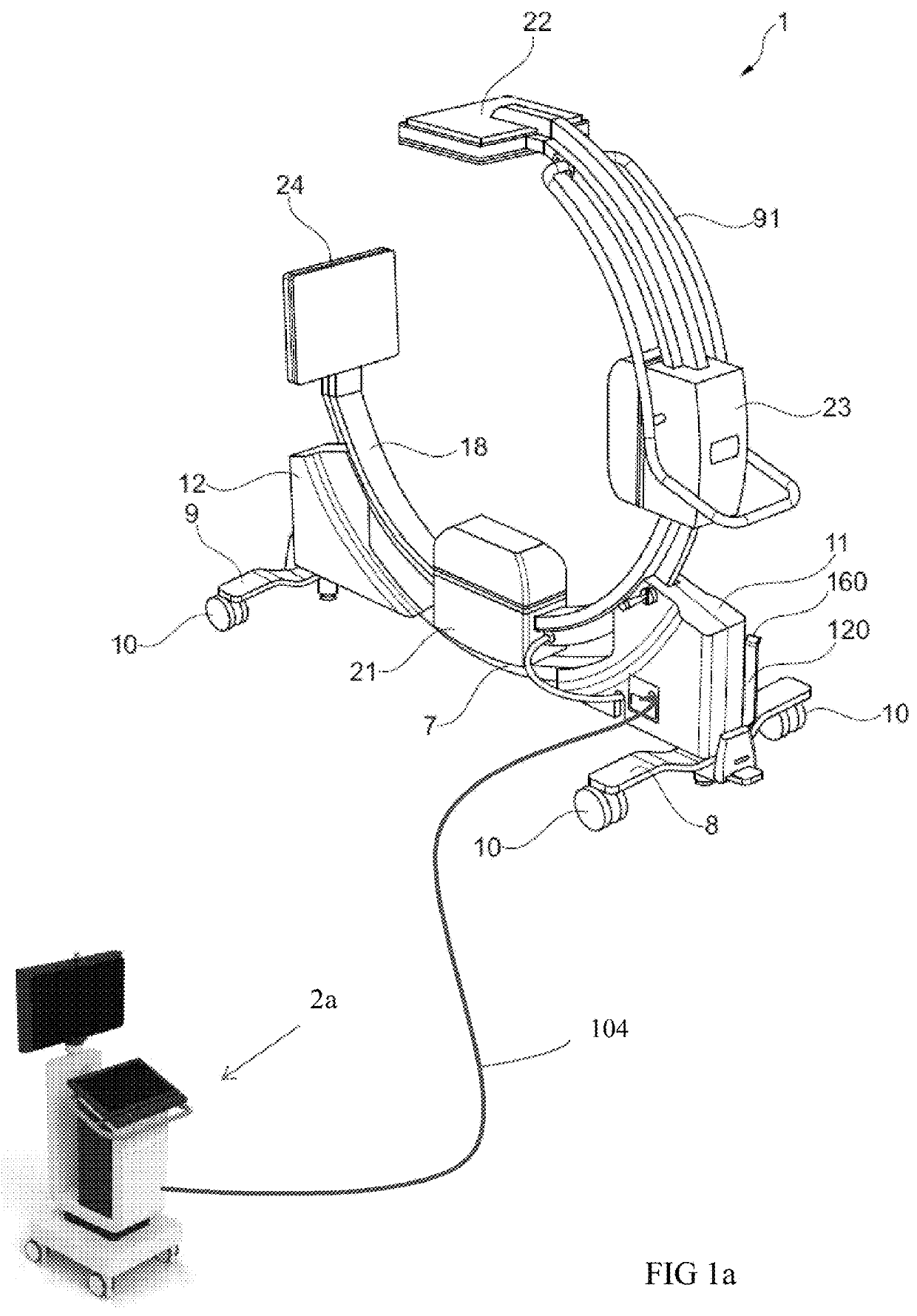

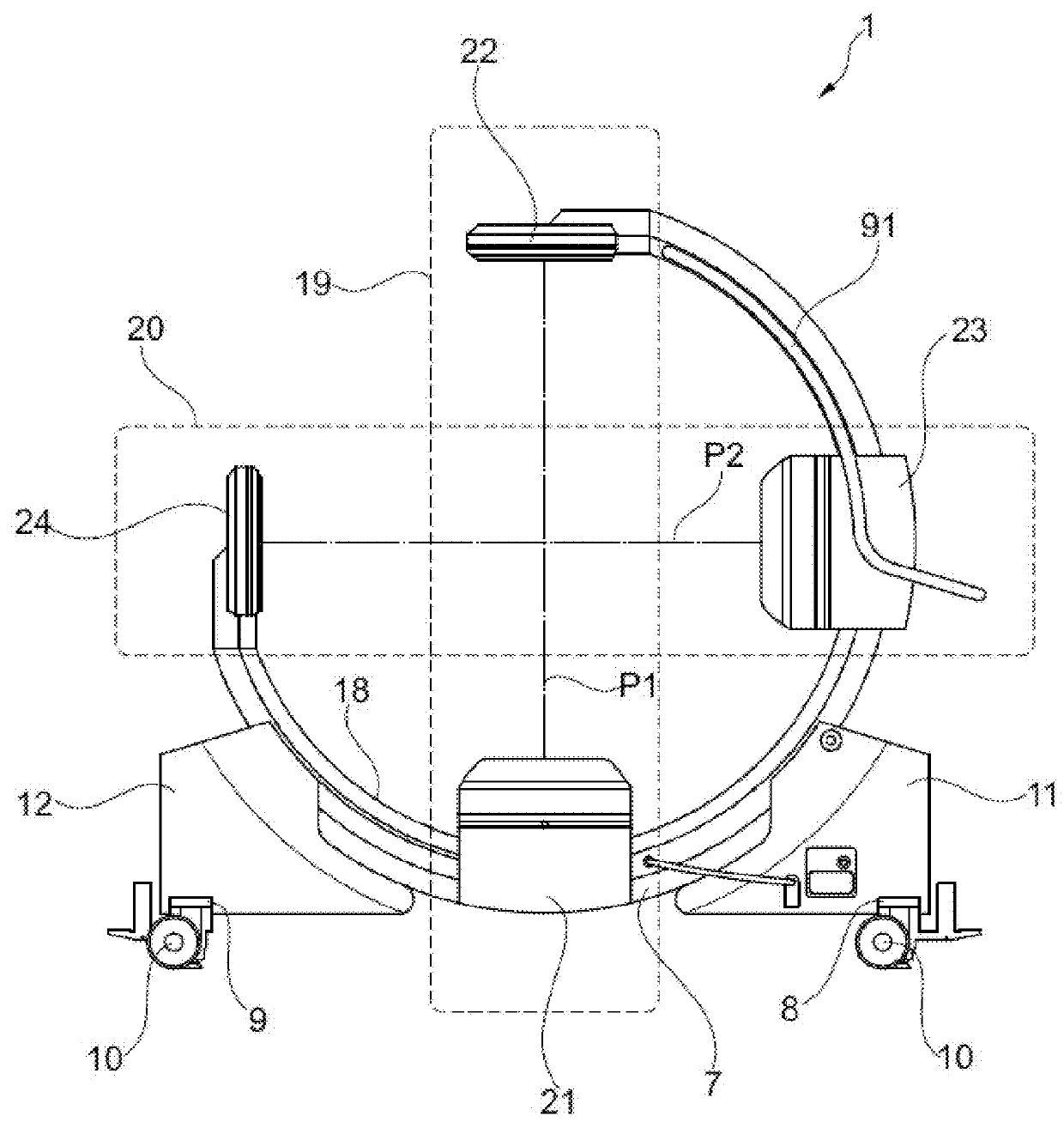

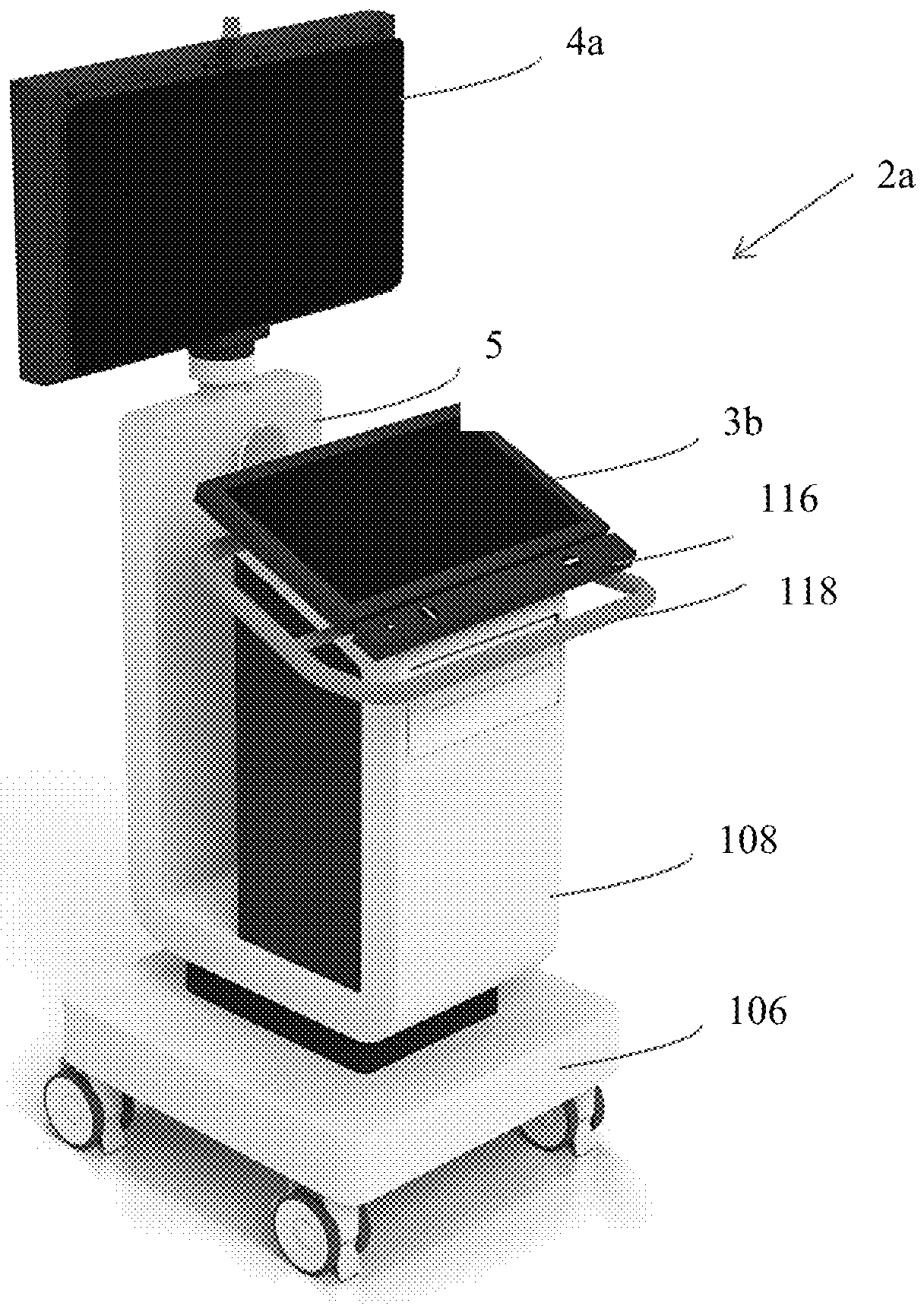

ActiveUS10004469B2Narrowing area of interestNeed lessRadiation diagnosis data transmissionX-ray apparatusControl signalFluorescence

A mobile digital fluoroscopy system comprising a mobile X-ray system carrier unit (1) comprising a first and a second X-ray device (19, 20) each having a transmitter (21, 23) and a receiver (22, 24), wherein said respective first and second X-ray devices (19, 20) are configured to enable X-ray imaging in mutually intersecting planes, a kV unit1012; and; wherein said a mobile control unit (2a) is communicatively coupled to the mobile X-ray system carrier (1) via a cable (150), wherein said mobile control unit (2a) is configured to receive a first set of image data 810 from said kV unit (1012) and sending a control signal to said kV unit (1012) upon completion of receiving of said image data 810, wherein kV unit 1012 is configured to generate a synchronization signal 820 to said transmitters (21, 23) and receivers (22,24) and to send a second set of image data 810 received from receivers (22,24) to the mobile control unit 2a.

Owner:SCANFLEX HEALTHCARE

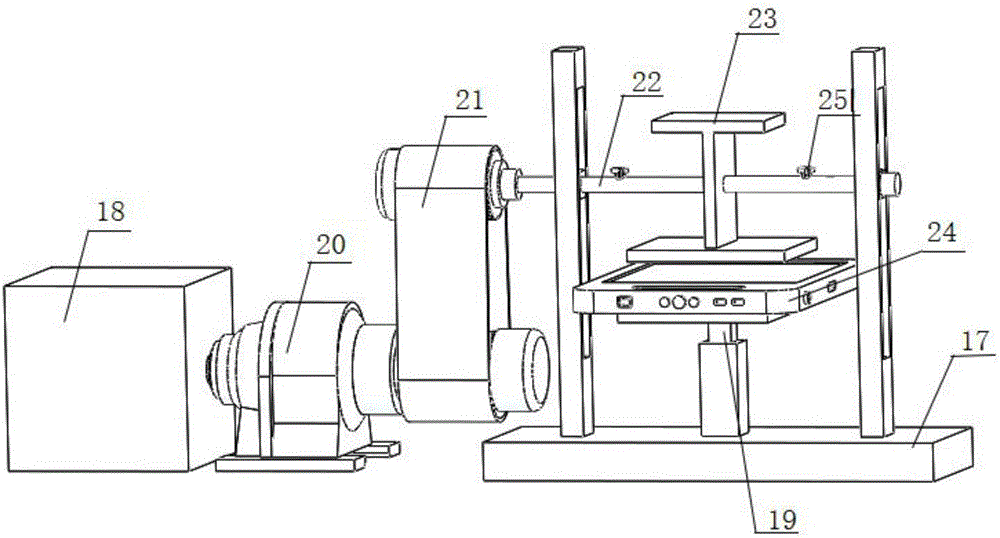

X-ray real-time imaging detecting system and detecting method for detecting defects of H-shaped weld component

ActiveCN105758877ARealize detectionImprove detection efficiencyMaterial analysis by transmitting radiationSoft x rayFlat detector

The invention discloses an X-ray real-time imaging detecting system for detecting defects of an H-shaped weld component.The X-ray real-time imaging detecting system comprises a picture monitoring device, an X-ray real-time imaging control device, an industrial robot, an end actuator, a portable X-ray generator, a clamping platform, a control module, a lifting device, a driving device, a transmission gear and the H-shaped weld component.One end of the lifting device is fixed onto a horizontal platform of the clamping platform, a flat detector is arranged at the other end of the lifting device, an output end of the flat detector is connected with the X-ray real-time imaging control device, the driving device is connected with a fixture by the transmission gear, and the control module is connected with the driving device, the lifting device and the X-ray real-time imaging control device.The X-ray real-time imaging detecting system has the advantages that the X-ray generator is fixed by the aid of the industrial robot, is controlled by the aid of the industrial robot and can be repositioned by the aid of the industrial robot, transmission angles of the X-ray generator can be adjusted by the aid of the industrial robot, the H-shaped weld component can rotate by the aid of the control module, the driving device and the transmission gear and can be matched with position and angle change of the X-ray generator, accordingly, various weld seam portions of the H-shaped weld component can be detected, and the detection efficiency and the detection precision can be improved.

Owner:射阳县天鼎检测设备有限公司

Method for combined bone hardening and scattered radiation correction in X-ray computed tomography

InactiveUS7782996B2Accurate methodGood compensationMaterial analysis using wave/particle radiationRadiation/particle handlingArithmetic logic unitX-ray

The invention relates to a method for combined bone hardening and scattered radiation correction in X-ray computed tomography of a heterogeneous object with a CT system comprising an X-ray source moved around an object, a flat detector with a large number of distributed detector elements which detect measuring beams from a focal point of the X-ray tube, and a control and arithmetic-logic unit—by iterative reconstruction and segmented vectorial reprojection calculation, wherein a scattered radiation correction and a radiation hardening correction are carried out in each iteration cycle for at least two different material components of the object being examined. The invention also relates to an X-ray CT system for carrying out this method.

Owner:SIEMENS HEALTHCARE GMBH

Optical Sensor, in Particular Proximity Switch

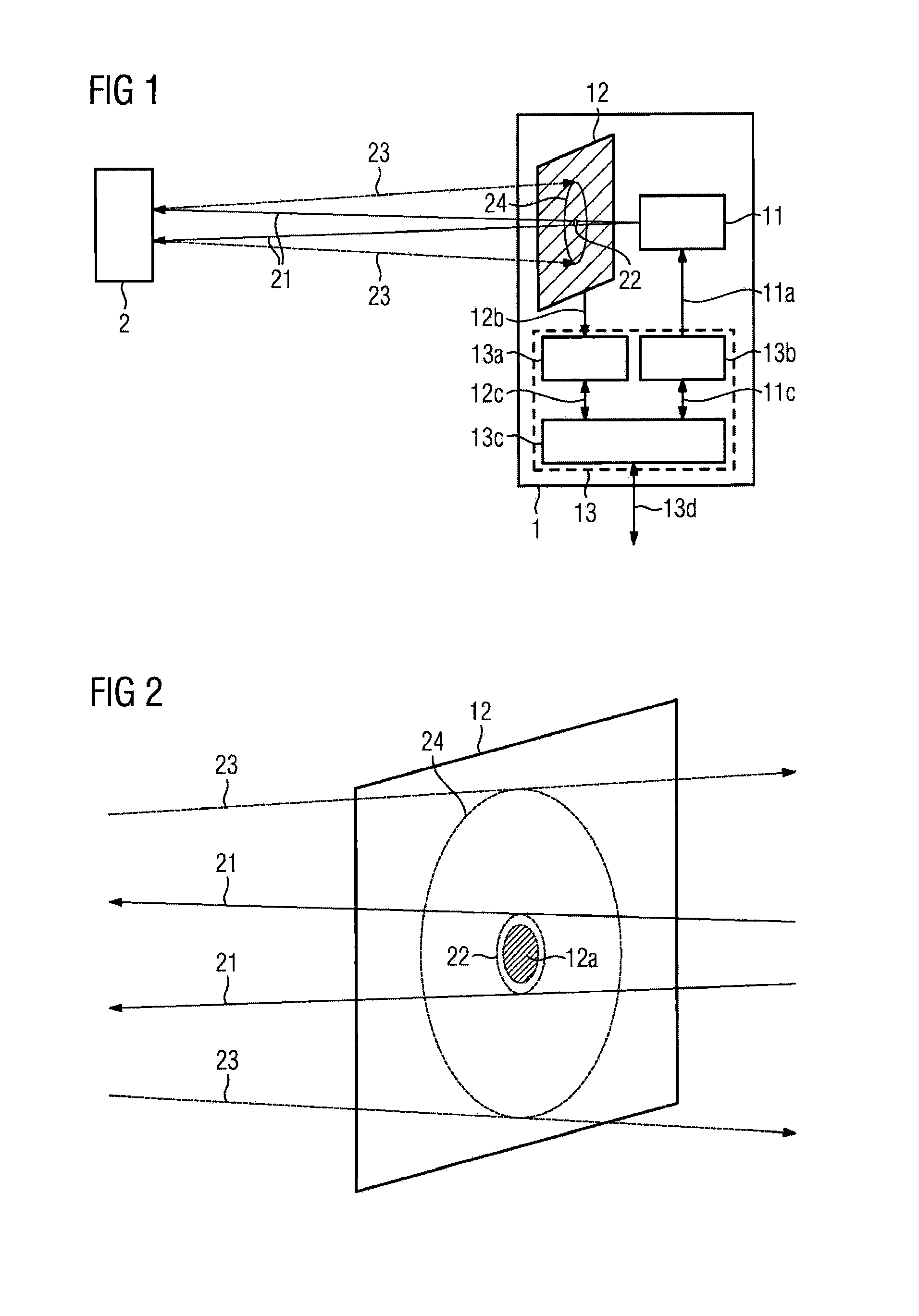

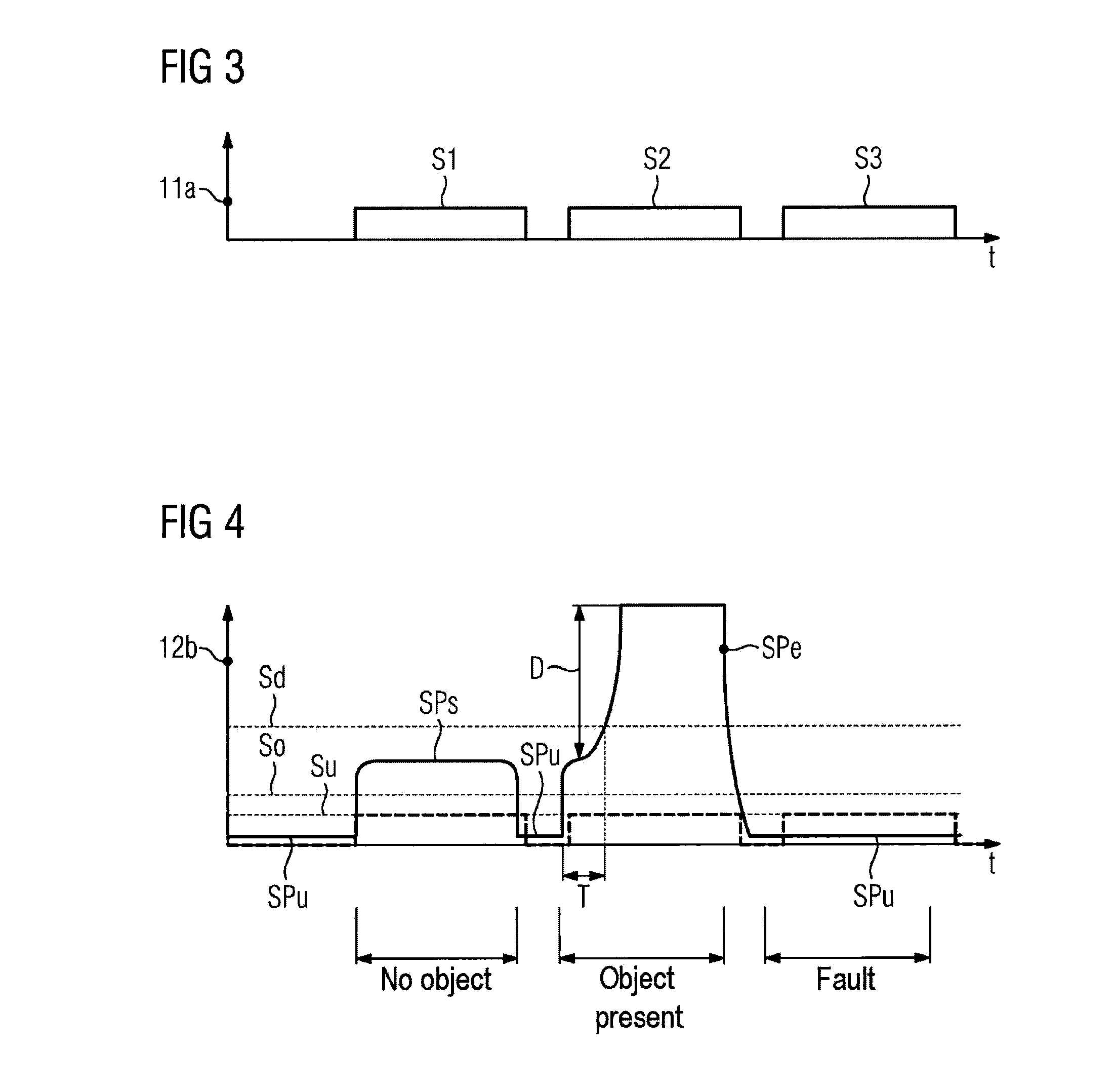

ActiveUS20130001406A1High transmission powerSmall dimensionBeam/ray focussing/reflecting arrangementsSolid-state devicesFlat detectorFlat panel

An optical sensor having at least one optical transmitting unit for production of a transmitted light beam, a photosensitive flat detector with semitransparent characteristics, through which the transmitted light beam passes, and which re-receives reflection light beams, i.e., from an object, and an evaluation unit for the photoelectric current of the photosensitive flat detector, at least for detection of an object. The photosensitive flat detector advantageously includes an organic polymer layer comprising a photosensitive substrate. An “Organic Photosensitive Diode” (OPD) is particularly advantageously used as the photosensitive flat detector with semitransparent characteristics.

Owner:SIEMENS HEALTHCARE GMBH

Device and method for analyzing a materials library

InactiveUS7479636B2Speeding up determinationPossible to developRadiation pyrometryColor/spectral properties measurementsImage resolutionLight beam

A device for analyzing a materials library includes at least one radiation source for electromagnetic radiation, which is positioned in front of the materials library, and at least two flat detectors operating in parallel, which are operable using high-sensitivity resolution and of which one is sensitive to electromagnetic radiation of a first wavelength range and the other is sensitive to electromagnetic radiation of a second wavelength range. Moreover, a method for analyzing a materials library in which the materials library is simultaneously tested using at least two methods in which electromagnetic radiation of different wavelength ranges is used. The beam is split behind the materials library as a function of wavelength and is deflected in the direction of at least two flat sensors operating using high-sensitivity resolution.

Owner:ROBERT BOSCH GMBH

Radiography device for recording dynamic processes and associated recording method

ActiveUS20070286334A1Reduce loadReduce radiation loadRadiation/particle handlingX-ray apparatusFlat detectorX-ray

There is described a radiography device for recording dynamic processes and an associated recording method. The radiography arrangement is used to examine patients using an x-ray source, a digital flat detector with a single shot recording function and an operating console for controlling and recording purposes, with the flat detector also being able to display an image sequence at a rate of up to 5 Hertz, which allows the positioning of the region to be examined or the monitoring of pseudo-interventional interventions.

Owner:SIEMENS HEALTHCARE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com