X-ray nondestructive inspection integral remote control platform for electric equipment

A remote control platform and non-destructive testing technology, applied in the direction of material analysis using radiation, etc., can solve the problems of time-consuming, laborious, inefficient, imaging display and vehicle platform adjustment can not be unified, to reduce cumbersomeness, improve efficiency, mobile Convenient and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

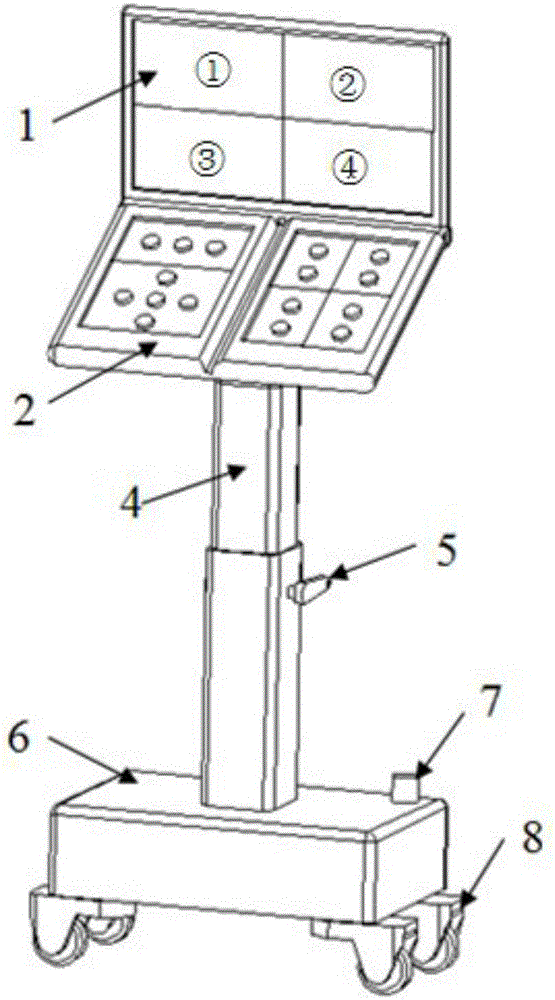

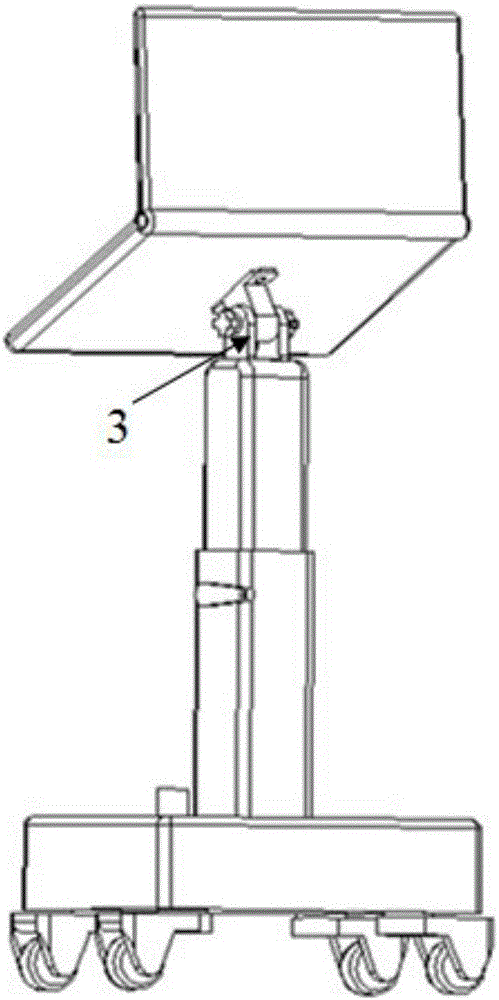

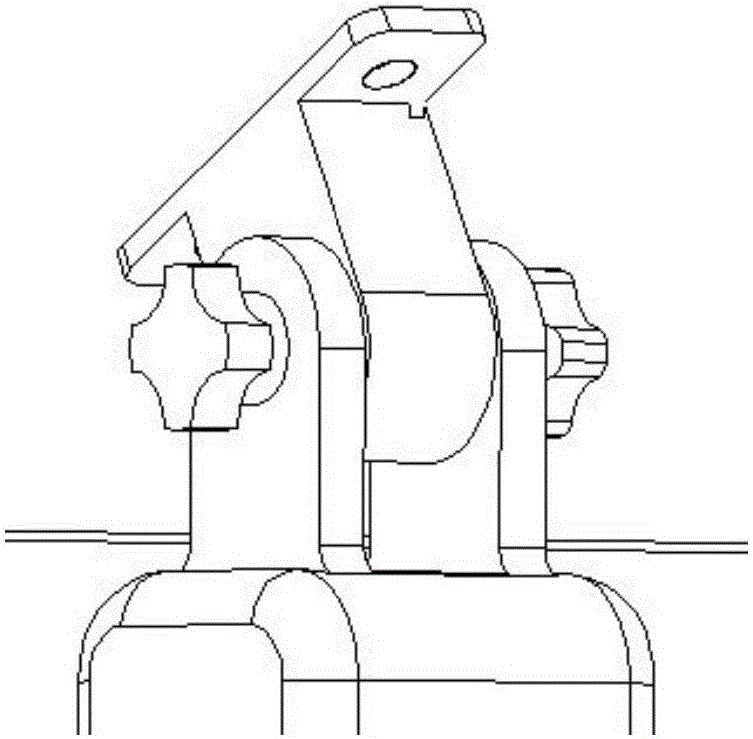

[0024] Embodiments of the present invention are described below in conjunction with the accompanying drawings, see figure 1 with figure 2 ,

[0025] A comprehensive remote control platform for X-ray non-destructive testing of electrical equipment, including a display screen 1, a console 2 hingedly connected with the display screen 1, and a telescopic support column 4 supporting the console 2, which is arranged between the support console 2 and the telescopic The angle regulator 3 between the telescopic support columns 4, the adjustment handle 5 for adjusting the telescopic support column 4 telescopic tubes on the telescopic support column 4 sleeves, the telescopic support column 4 is fixed on the belt universal wheel 8 On the mobile trolley 6, a signal antenna 7 is arranged on the mobile trolley 6, which is used for receiving and sending all signals between the remote control platform and the vehicle-mounted platform of the detection instrument; the interior of the mobile tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com