Seamless optical splicing method for 3*3 flat detectors

An area array detector, optical splicing technology, applied in optics, optical components, instruments, etc., can solve the problems of many times of light splitting, the relative relationship between prisms is independent and not concentrated, and the position is asymmetric, so as to achieve small volume and light weight structure, prism Strong and reliable, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

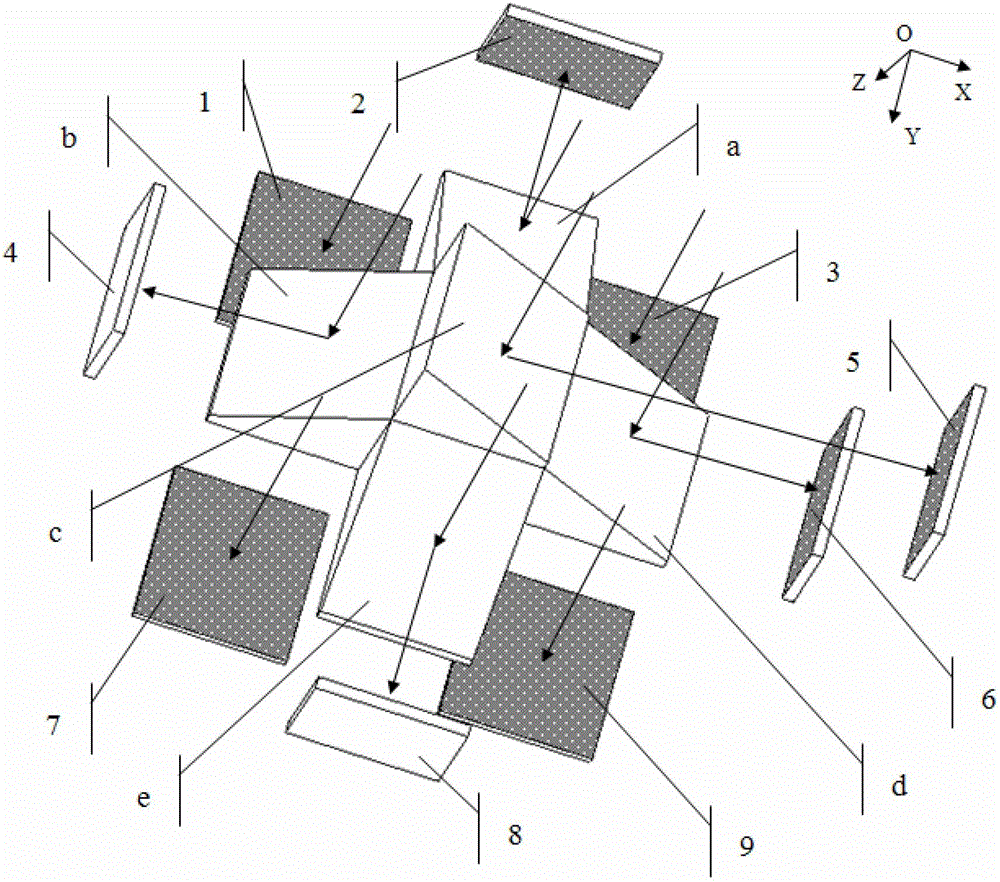

[0029] like figure 1 As shown, the present invention includes 5 reflecting prisms and 9 area array detectors, such as 10k×10k area array detectors.

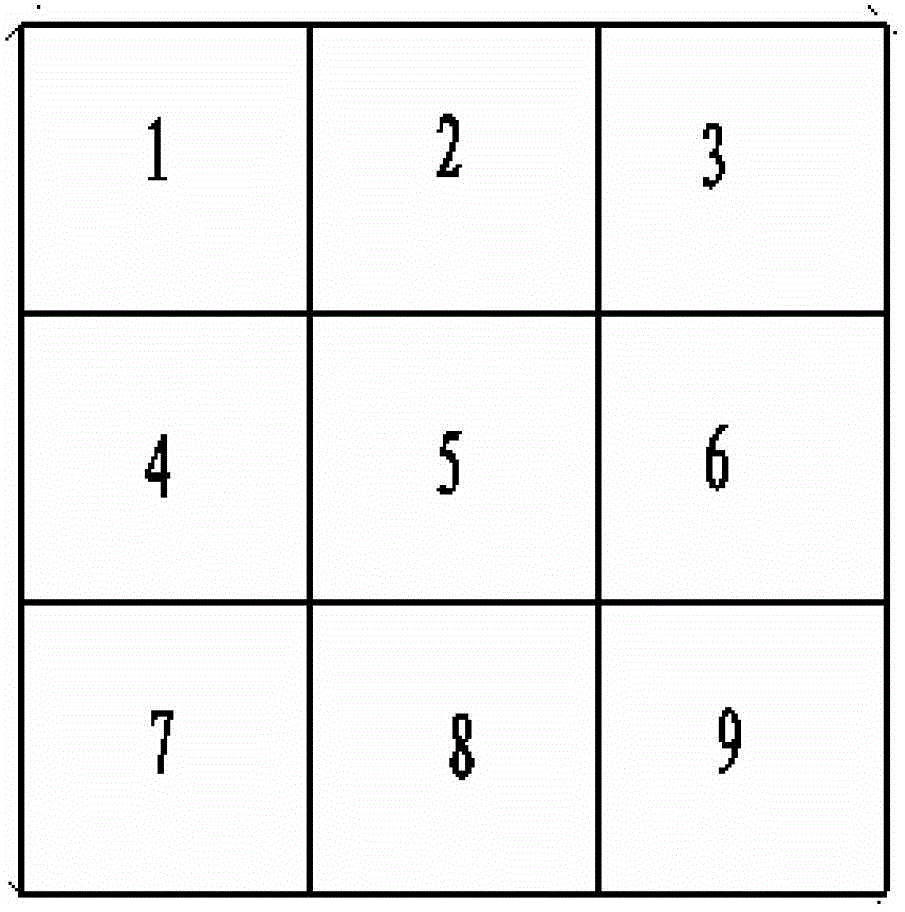

[0030] like figure 2 As shown, the combined image plane arrays are numbered from top to bottom and from left to right, that is, the top row is the first row, the bottom row is the third row; the leftmost column is the first column, and the rightmost column is the third row. List. The first row is area array detectors 1~3, the second row is area array detectors 4~6, and the third row is area array detectors 7~9; the combined image plane is divided according to the array and the 9 area array detectors are respectively combined correspondingly Areas 1 to 9 on the image plane.

[0031] Establish a space rectangular coordinate system, the origin O is located in the upper left corner of the image plane; the X axis is the column increasing direction, that is, from left to right; the Y axis is the row increasing direction, that is, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com