Method and assembly for light sheet microscopic analysis of a sample

A microscope and light sheet technology, applied in microscopes, optics, optical components, etc., can solve problems such as limitations, complex preparation, low light efficiency, phase deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

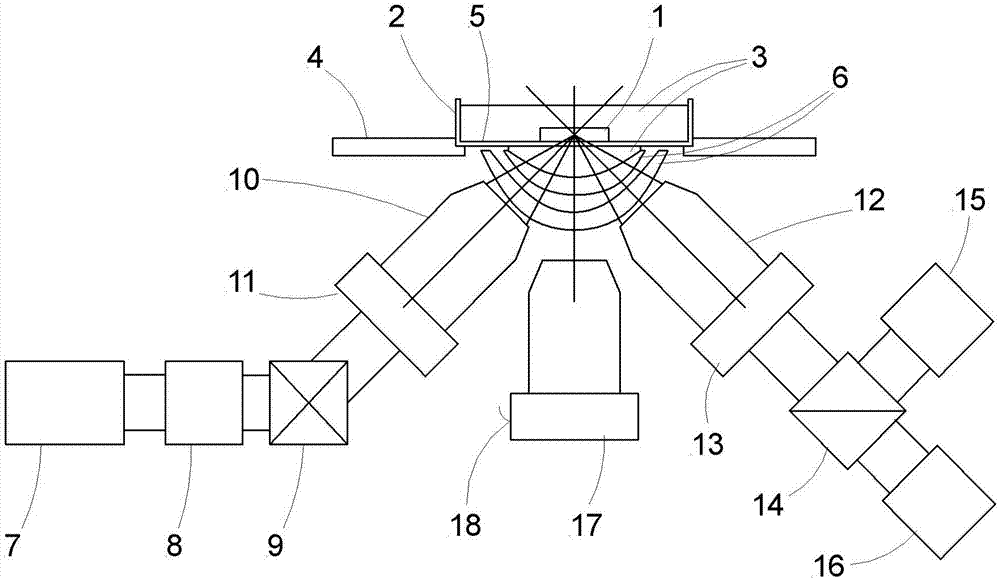

[0069] figure 1 First, the basic structure of the light sheet microscope is shown, and the sample can be detected by means of the light sheet microscope. Here, the light sheet microscope is shown in an inverted configuration, which is only to be understood as an example in which light microscopes are also possible configurations in which the sample can be observed from above or from the side. The sample 1 is located in the sample chamber 2 and is surrounded by a liquid 3 , for example water or a nutrient solution. The sample chamber 2 has side walls and a bottom made of glass with a predetermined thickness, for example equal to the thickness of a conventional microscope slide, for example 0.17 mm. The sample chamber 2 is supported on a microscope stage 4 , which can be moved manually or by a motor in three spatial directions. The individual components of the light sheet microscope are arranged below the sample chamber 2 , which has a transparent bottom 5 . Between the objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com