X-ray real-time imaging detecting system and detecting method for detecting defects of H-shaped weld component

A real-time imaging and detection system technology, applied in the direction of using radiation for material analysis, can solve problems such as immobility, and achieve the effect of improving detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

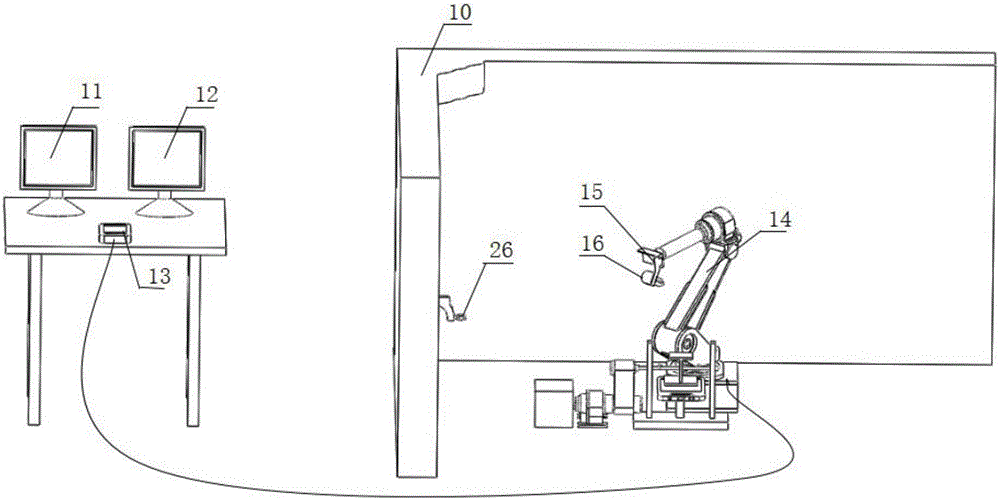

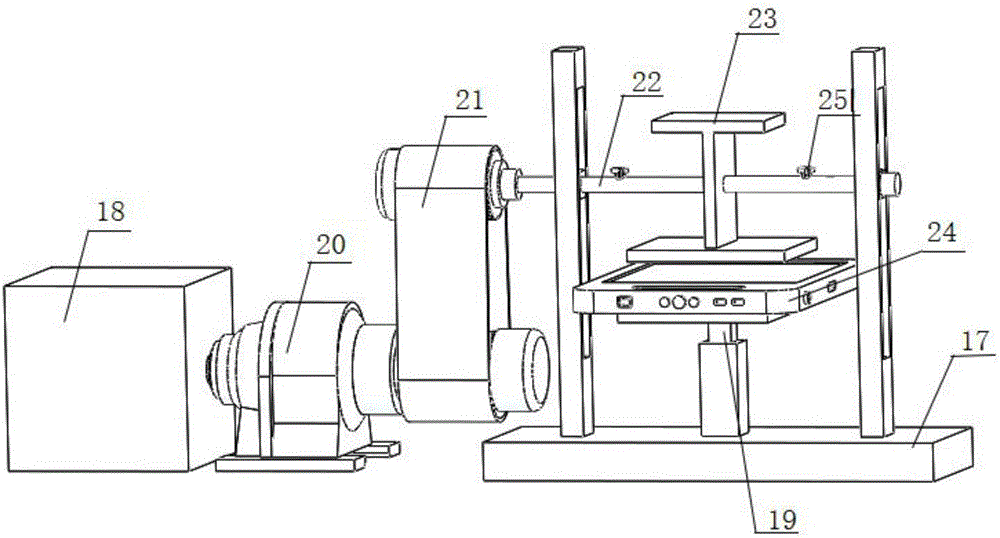

[0021] Such as figure 1 and figure 2 As shown, the X-ray real-time imaging detection system for detecting I-shaped weldment defects of the present invention includes a picture monitoring device 11 arranged outside the protective lead room 10, an X-ray real-time imaging control device 12 arranged in the protective lead room 10, a connection The camera 26 of the picture monitoring device 11, the industrial robot 14 connected with the robot control panel 13, the end effector 15 installed on the flange at the end of the industrial robot 14, and the portable X-ray machine 16 installed in the end effector 15 , a clamping platform 17, a control module 18, a lifting device 19, a driving device 20, a transmission device 21, a clamp 22 installed in the clamping platform 17, and an I-shaped weldment 23 fixed in the clamp 22. In order to see the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com