Scintillator plate for ray detection flat detector and preparation method for the same

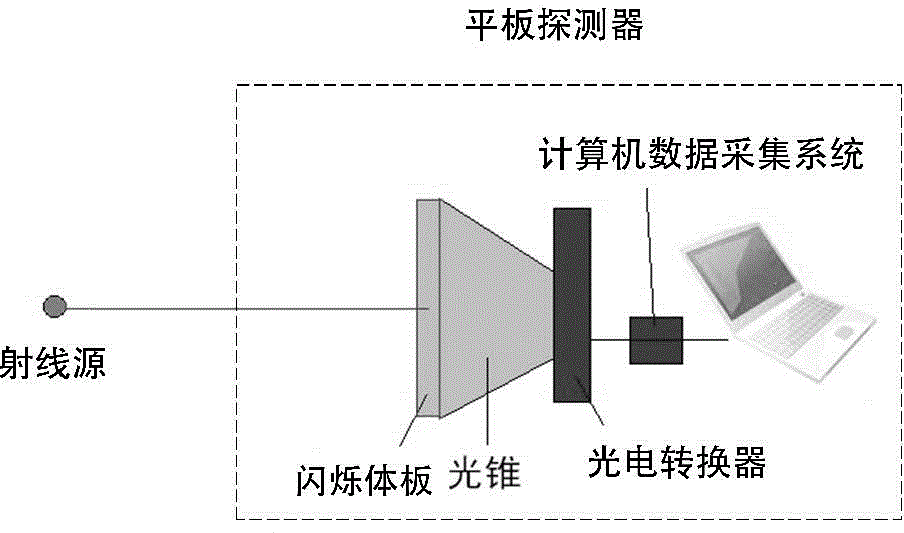

A flat-panel detector and ray detection technology, applied in radiation intensity measurement and other directions, can solve the problem of detection performance of detectors without etched array units, and achieve the effects of low maintenance cost, long service life, and improved system imaging resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

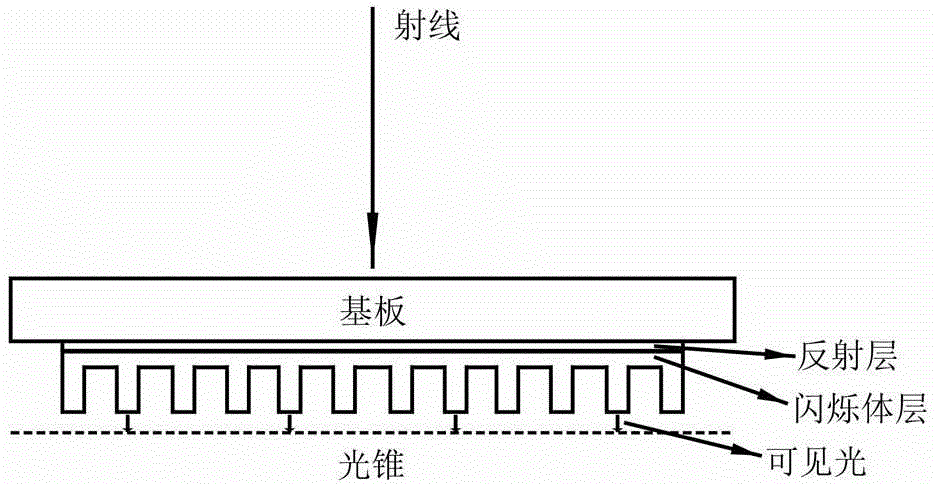

[0070] On the other hand, the present invention also provides a method for preparing the transparent ceramic scintillator plate, comprising: preparing a transparent ceramic scintillator by using a solid-phase reaction method or a liquid-phase method combined with ceramic sintering technology according to the chemical composition of the transparent ceramic scintillator; The prepared transparent ceramic block is processed and cut into a scintillator of a certain size; the transparent ceramic scintillator and the substrate material are fixed through a reflective layer; the multilayer composite structure is polished to a certain thickness; and the composite structure is The scintillator layer is cut into rectangular arrays.

[0071] The preparation method of the transparent ceramic used in the scintillator layer includes:

[0072] (1) Preparation of raw material mixed powder;

[0073] In one example, according to the chemical composition of the transparent ceramic scintillator (L...

Embodiment 1

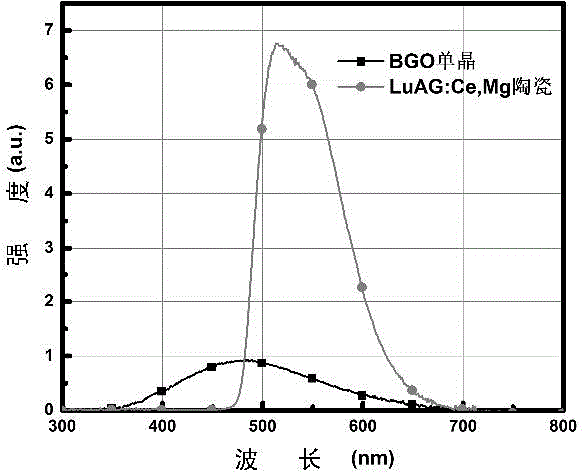

[0100] Using lutetium oxide (Lu 2 o 3 ), alumina (Al 2 o 3 ), magnesium oxide (MgO), cerium oxide (CeO 2 ) as raw material, according to (Lu 0.995 Ce 0.003 Mg 0.002 ) 3 al 5 o 12 Composition Accurately weigh 60g of the powder raw material, and then use absolute ethanol as the dispersion medium for ball milling and mixing. After ball milling for a certain period of time, the two powders are dried and sieved respectively; then they are pressed into tablets and subjected to 200MPa cooling etc. Static pressure into a green body; then put it into a vacuum or hot-press sintering furnace at 1880 ° C for 20 hours to obtain (Lu (1-x-y) Ce x Mg y ) 3 al 5 o 12 Ceramics, the resulting ceramic material is polished to obtain transparent ceramics with high optical quality. The transparent ceramics were ground, polished and cut to 20×20×2 mm. The linear transmittance of the transparent ceramic reaches 73% at 800nm, and the luminous intensity reaches 7.5 times that of BGO sing...

Embodiment 2

[0102] When preparing the scintillator plate, the thickness of the scintillator layer was 50 μm, but laser cutting was not performed, and other conditions were the same as in Example 1. The flat-panel detector adopts the lead wire-to-card method to test the MTF at 10lp / mm, and the MTF is 13.0%. The knife-edge method is used to test the RQA5 experimental conditions specified in the standard IEC62220-1. When the MTF is 10%, the resolution is 6lp / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com