Moment balancer

A technology of moment balance and force arm, applied in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as affecting the stability of the system and the adverse effects of the normal operation of the X-ray machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention

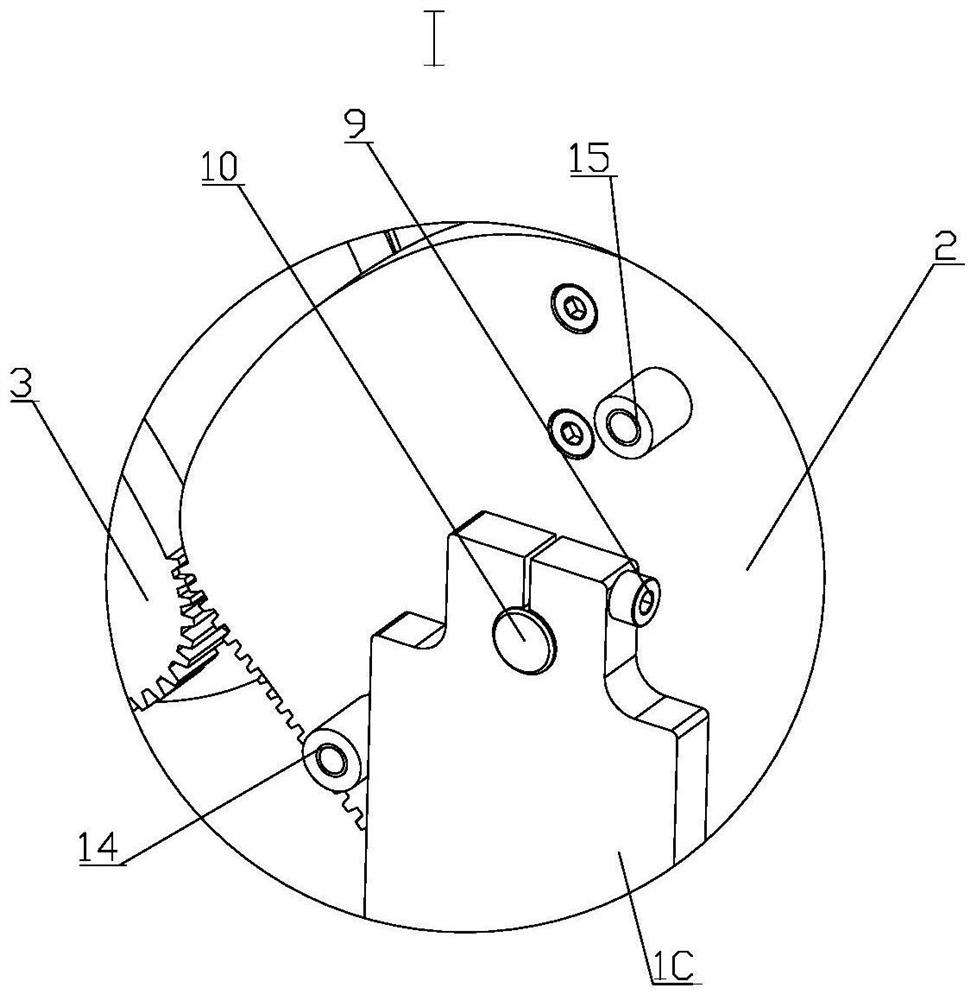

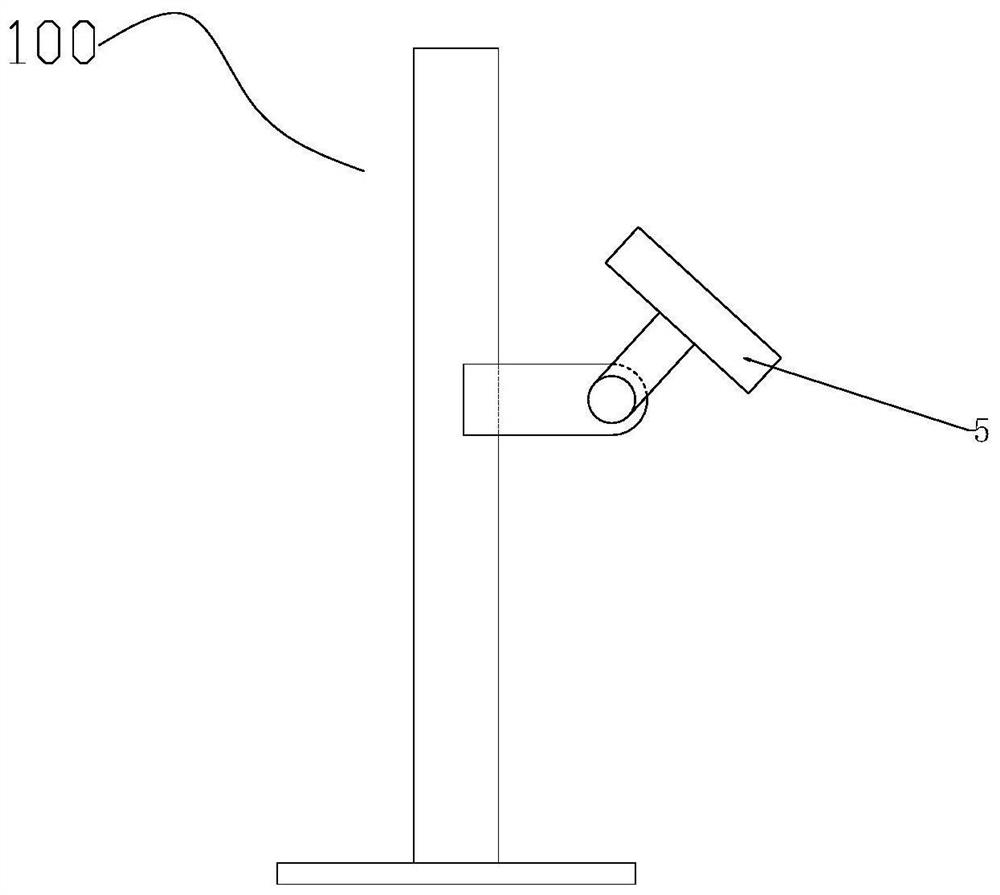

[0056] Such as Figure 3 ~ Figure 6 A moment balancer shown includes a base assembly 1, a driving gear 3 and a driven gear 2 which are arranged on the base assembly 1 and mesh with each other, an energy storage device 6 connected with the driving gear 3, and a driven gear 2 connected to the Connected load5.

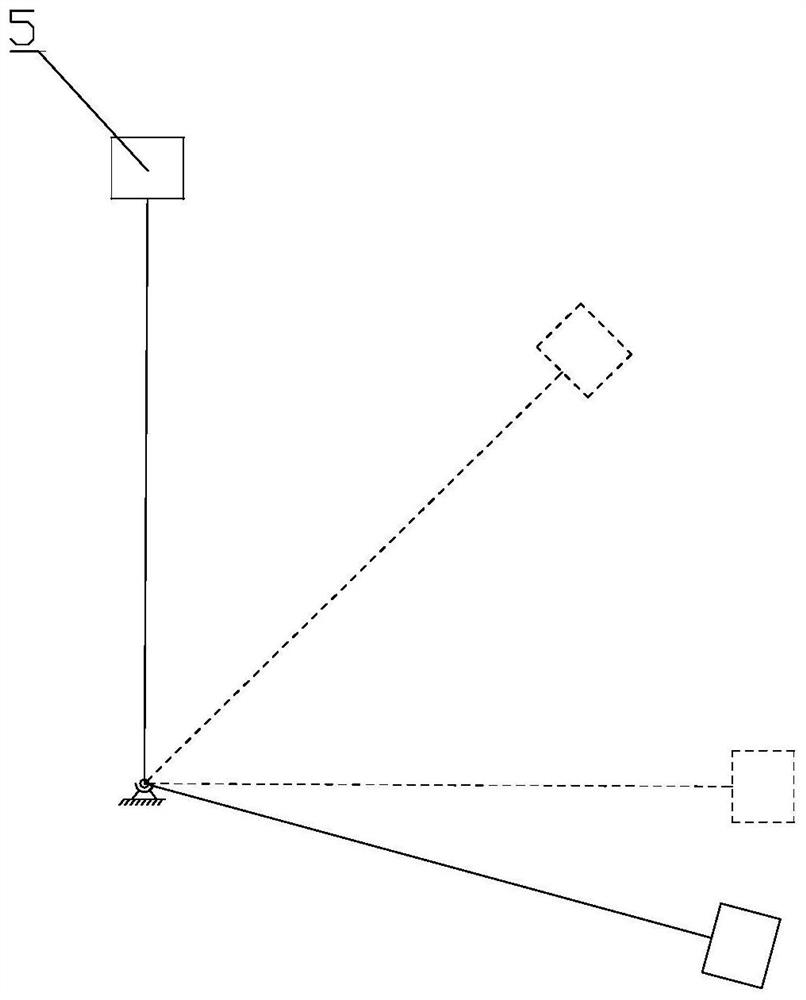

[0057] Such as Figure 13 with Figure 14 As shown, the driving gear 3 revolves around its own main gear center O 1 Rotation, the driven gear 2 revolves around itself from the gear center O 2 Autorotation; between the driving gear 3 and the driven gear 2, a variable transmission ratio transmission is performed and a node P for position change is formed. The node P is known by common knowledge and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com