Gadolinium oxysulfide sintered body, and scintillator, scintillator array, radiation detector, and radiation inspection apparatus including gadolinium oxysulfide sintered body

A technology of gadolinium oxysulfide and sintered body, which is applied in the field of scintillators, can solve the problems of X-ray sensitivity reduction and achieve high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

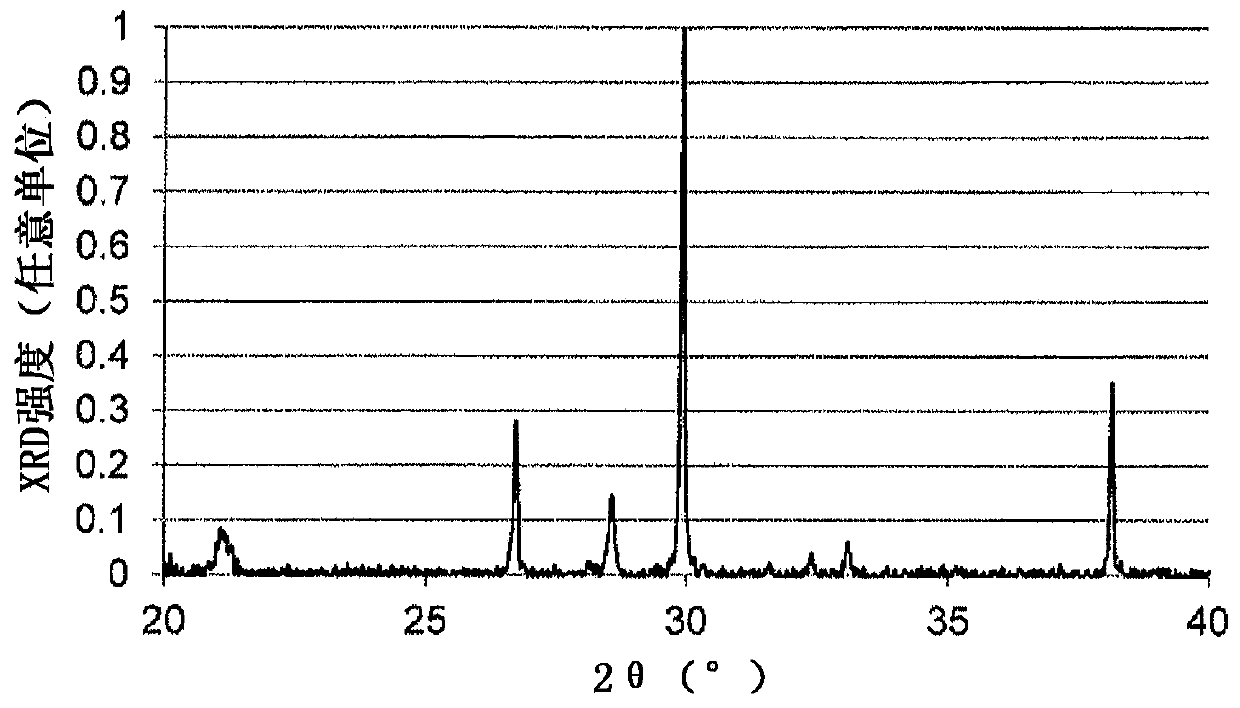

Image

Examples

Embodiment 1

[0088] ·Sintering process

[0089] Gd with an average particle size of 9 μm on a volume basis 2 o 2 S: The powder of Pr phosphor is sealed in a low-carbon steel capsule, and the HIP treatment is performed at a temperature of 1300 °C and a pressure of 100 MPa for 2 hours to obtain Gd 2 o2 S: Sintered body of Pr.

[0090] Next, the obtained sintered body was processed into a thickness of 6×6×3 mm with a dicing saw to obtain a sintered body sheet.

[0091] ·Annealing process

[0092] Put the obtained sintered body into Gd 2 o 2 S:Pr phosphor powder, in the sintered sheet and Gd 2 o 2 S: Pr phosphor powder was placed in a crucible made of alumina in a state of contact with the phosphor powder, and the crucible was placed in a Taman high-temperature electric furnace SUPER-BURN manufactured by Motoyama Corporation. In an argon (0.3L / min) atmosphere, the temperature was raised to 1100°C at 200°C / hour, and after heat treatment for 10 hours, the temperature was lowered at 200°C...

Embodiment 2~4、 comparative example 1~2

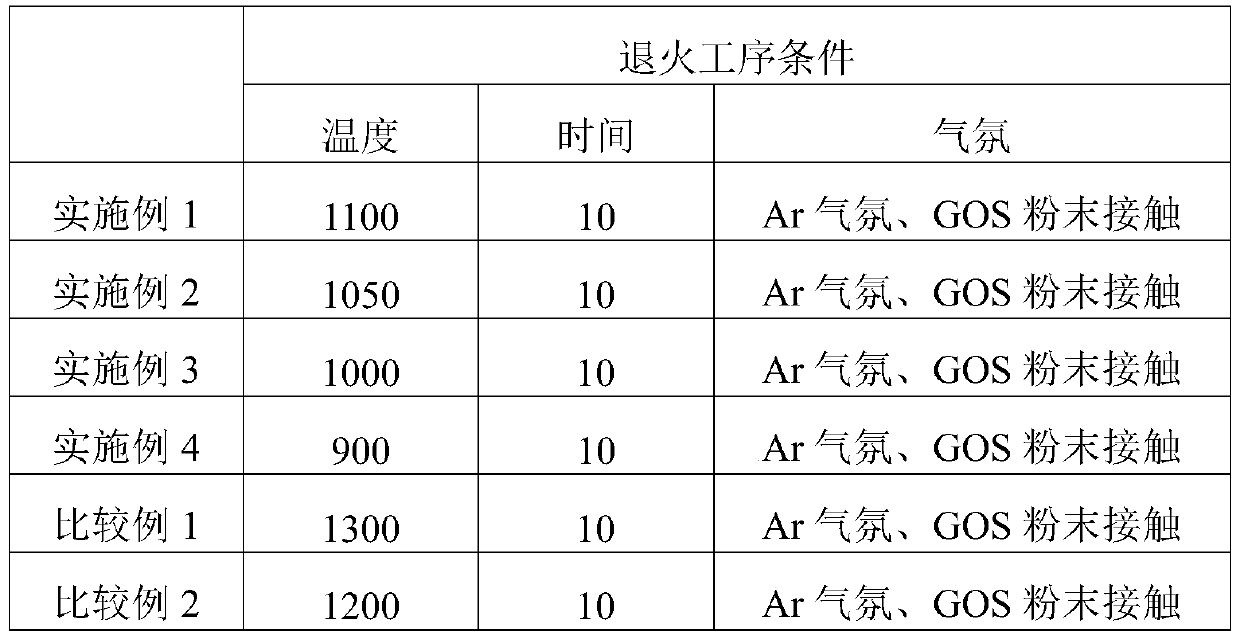

[0102] Using the sintered compact sheet obtained in Example 1, Gd was obtained in the same manner as in Example 1 except that the temperature of the annealing step, the time of the annealing step, and the atmosphere of the annealing step were changed according to Table 1. 2 o 2 S: Pr sintered body.

[0103] [Table 1]

[0104] Table 1

[0105]

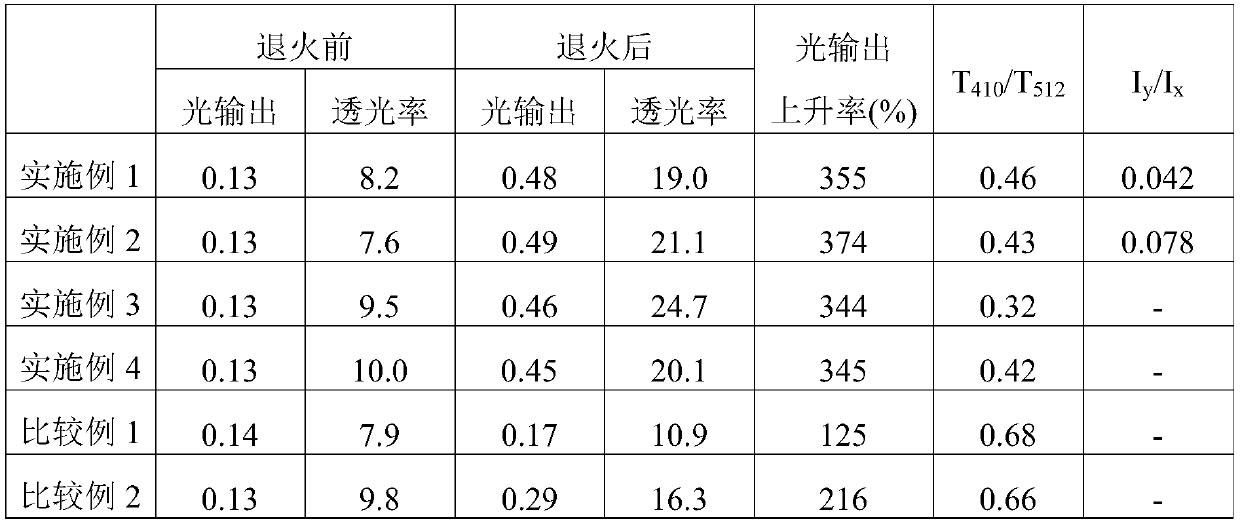

[0106] [Table 2]

[0107] Table 2

[0108]

Embodiment 5

[0110] ·Sintering process

[0111] A sintered compact sheet was obtained by the same method as in Example 1.

[0112] ·Annealing process

[0113] Put the obtained sintered body into Gd 2 o 2 S:Pr phosphor powder, in the sintered sheet and Gd 2 o 2 S: Pr phosphor powder was placed in a crucible made of alumina in a state of being in contact with the phosphor powder, and the crucible was placed in a Taman high-temperature electric furnace SUPER-BURN manufactured by Motoyama Corporation. In an argon (0.3L / min) atmosphere, the temperature was raised at 200°C / hour to 1050°C, and after heat treatment for 10 hours, the temperature was lowered at 200°C / hour to obtain Gd after the annealing process. 2 o 2 S: Pr sintered body.

[0114] The annealing process conditions of the sintered body obtained in Example 5, the light output after annealing, and the transmittance T 410 / T 512 , I y / I x Shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com