Hot-pressing reaction sintering method of gadolinium oxysulfide scintillation ceramics

A technology of scintillation ceramics and gadolinium oxysulfide, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of affecting luminescence performance, being unsuitable for preparing gadolinium oxysulfide ceramics, affecting scintillation performance, etc., and achieving a simple process. , good matching, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

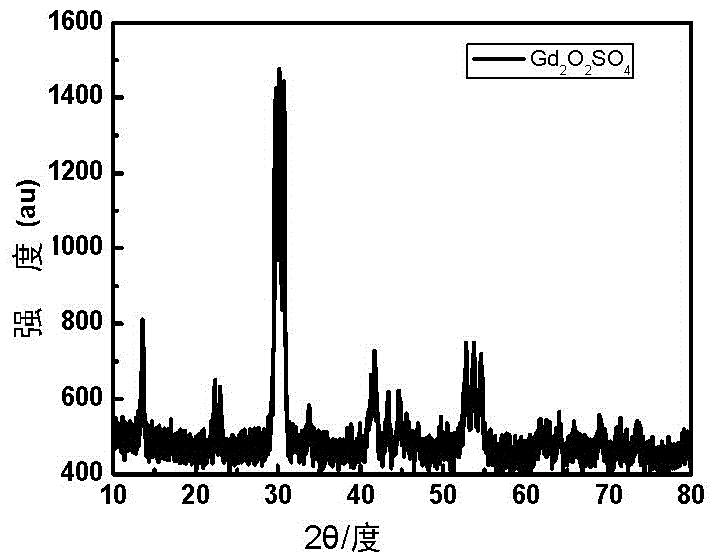

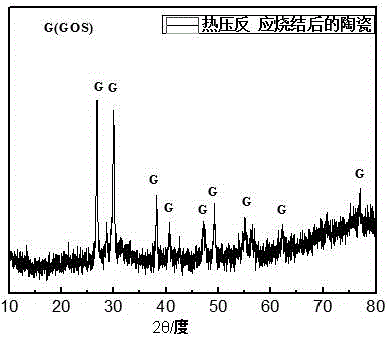

[0045] Weigh 30g Gd 2 o 2 SO 4 Powder, 0.012g of hexapraseodymium oxide powder, 0.4g of activated carbon, put into an alumina ball mill jar, add 90g of alumina balls and a certain amount of ball milling medium, first ball mill at low speed for 30 minutes, then ball mill at high speed for 6 hours, take out and dry sieve. Weigh 3g of the above-mentioned mixture, pour it into a dry pressing mold with a diameter of 15mm, and keep the pressure at 10MPa for 2min. The heating rate of 10°C / min is raised to 850°C. During this process, the pressure is kept at 10MPa, and the pressure is kept at 850°C and 10MPa for 1 hour, and then the speed is raised to 1170°C at a rate of 10°C / min. After ℃, pressurize to 40MPa and hold for 2 hours to get Gd 2 o 2 S: Pr scintillating ceramics. Testing and characterization of ceramics after cutting and polishing. From figure 1 and figure 2 In the comparison, it can be seen that after thermal reaction sintering, the phase is changed from Gd 2 o ...

Embodiment 2

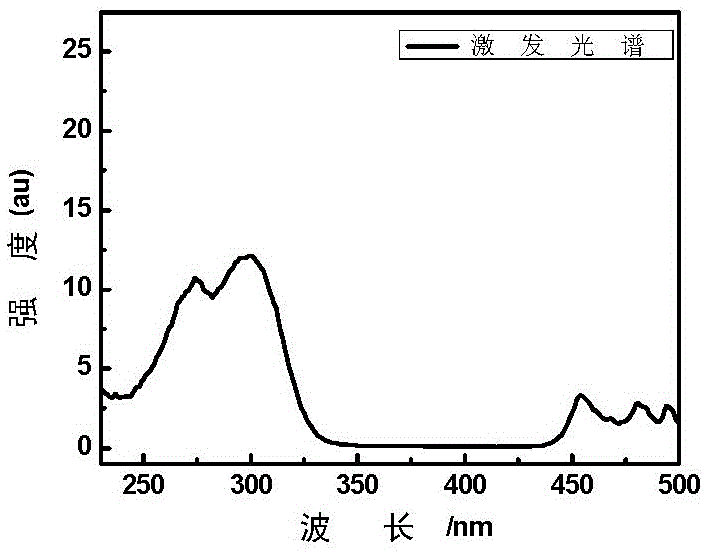

[0047] Weigh 50gGd 2 o 2 SO 4 Powder, 0.02g of hexapraseodymium oxide powder, 2.58g of activated carbon, put into an alumina ball mill jar, add 160g of alumina balls and a certain amount of ball milling medium, first ball mill at low speed for 30 minutes, then ball mill at high speed for 6 hours, take out and dry sieve. Weigh 4g of the above-mentioned mixture, pour it into a dry pressing mold with a diameter of 15mm, and keep the pressure at 10MPa for 2min. Raise the temperature to 950°C at a rate of 10°C / min, keep the pressure at 10MPa during this process, keep the pressure at 950°C and 10MPa for 1 hour, then rise to 1270°C at a rate of 10°C / min, keep the pressure at 20MPa during the heating process, and reach 1270°C After pressurizing to 40MPa, holding time for 2h, you can get Gd 2 o 2 S: Pr scintillating ceramics. Testing and characterization of ceramics after cutting and polishing. image 3 is the photoexcitation spectrum received at 513nm, where the absorption at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com