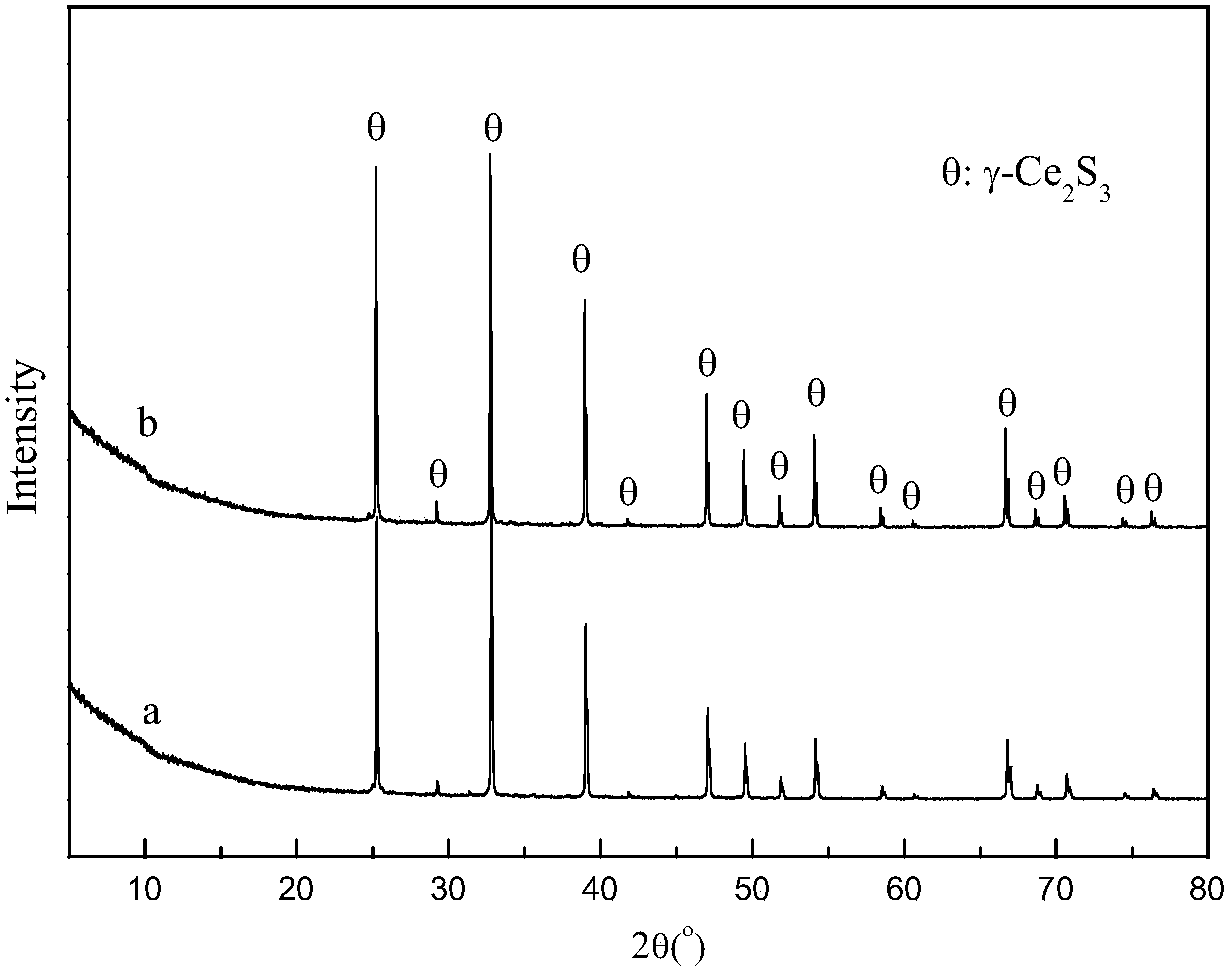

Zirconium silicate-coated low-valence ion co-doping gamma-Ce2S3 red pigment and preparation method thereof

A composite doping, red pigment technology, applied in the field of inorganic pigments, can solve the problems of insufficient thickness of the coating layer, unstable crystal structure, no longer showing bright red, etc. Control, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

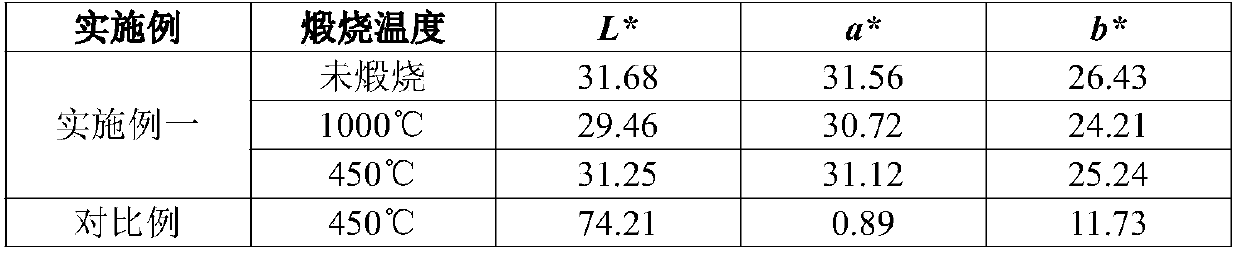

Examples

Embodiment 1

[0032] In this example, zirconium silicate-encapsulated low-valent ions are compositely doped with γ-Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0033] (1) Preparation of cerium oxysulfide precursor suspension containing doped ionic elements by solvothermal method

[0034] 3.5g CeCl 3 ·7H 2 O, 0.13g Eu 2 (SO 4 ) 3 ·H 2 O, 0.06g SnCl 2 2H 2 O and 0.4g of thiourea were dissolved in 70ml of ethylenediamine in turn, stirred vigorously for 120min, then transferred to a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 200°C for 12h to obtain Eu, Sn containing doping elements The cerium oxysulfide precursor suspension;

[0035] (2) Preparation of precursor mixture powder

[0036] Add 4.0g tetraethyl orthosilicate to the above suspension, adjust the pH value of the system to 11.0 with ammonia water, then slowly add 30ml of zirconium butoxide ethylenediamine solution (dissolved concentration is 0.8mol / L) to make tetraet...

Embodiment 2

[0042] In this example, zirconium silicate-encapsulated low-valent ions are compositely doped with γ-Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0043] (1) Preparation of cerium oxysulfide precursor suspension containing doped ionic elements by solvothermal method

[0044] 3.91g Ce(NO 3 ) 3 ·6H 2 O, 0.175g Eu 2 (SO 4 ) 3 ·H 2 O, 0.21g SmCl 3 ·6H 2 O and 0.35g of thiourea were dissolved in 70ml of ethylenediamine in turn, stirred vigorously for 100min, then transferred to a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 250°C for 15h to obtain Eu, Sm containing doping elements The cerium oxysulfide precursor suspension;

[0045] (2) Preparation of precursor mixture powder

[0046] Add 3.5g tetraethyl orthosilicate to the above suspension, adjust the pH value of the system to 10.5 with ammonia water, then slowly add 25ml of zirconium butoxide ethylenediamine solution (dissolved concentration is 0.8mol / L) to ma...

Embodiment 3

[0051] In this example, zirconium silicate-encapsulated low-valent ions are compositely doped with γ-Ce 2 S 3 The preparation method of red pigment differs from embodiment one in that:

[0052] The sulfur source in the present embodiment step (1) is tetraethylthiuram disulfide (C 10 h 20 N 2 S 4 ), consumption is 1.5g; In the step (2), silicon source is the sodium silicate ethylenediamine solution (dissolution concentration is 2.0mol / L) that 1.5g sodium silicate is dissolved in the ethylenediamine that makes; Step (3) The middle additive is calcium carbonate, and the consumption amount of the sintering aid diboron trioxide is 2.5wt% of the precursor powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com