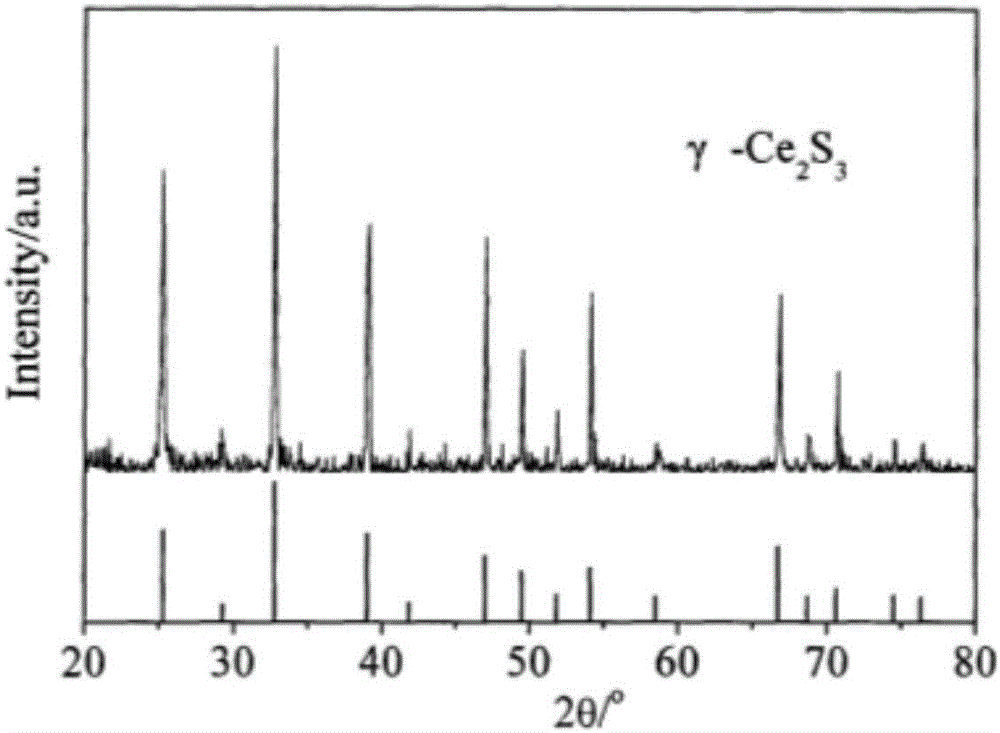

Method for preparing nano cerium sulfide by adopting liquid phase method

A technology of cerium sulfide and liquid phase method, which is applied in the field of preparation of nano-red cerium sulfide, can solve the problems of high toxicity of hydrogen sulfide gas, coarse cerium sulfide particles, low coloring rate, etc. Good uniformity and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 50g of mica powder (10-50 microns) at room temperature and dissolve in 1000ml of deionized water, stir evenly to make a bottom solution; add 246g of cerium chloride (CeCl 3 ), 18g sodium sulfide (Na 2 S), heated in a water bath at 90°C, added dropwise sodium carbonate solution (10wt%) to control the pH value to 10, and vigorously stirred (2000rpm) for 2h to generate a sol. The sol was filtered, washed 3 times with absolute ethanol, put into a 90° C. 4 SCN) mixed evenly, then put into the vacuum furnace, evacuate, heat up to 800°C at a rate of 10°C / min (if the heating rate is too fast, the grains will grow thicker, and if the heating rate is too slow, the production cycle will be lengthened), keep warm for 2 hours, and cool naturally After crushing, Na-doped cerium sulfide can be obtained. Take 75g of the above-mentioned cerium sulfide and dissolve it in 500ml of absolute ethanol, add 40ml of ammonia water (32%), then add 3.5g of ammonium fluoride and 2g of PVP, ...

Embodiment 2

[0037] Weigh 40g of mica powder (10-50 microns) at room temperature and dissolve in 1000ml of deionized water, stir evenly to make a bottom solution; add 246g of cerium chloride (CeCl 3 ), 9g sodium sulfide (Na 2 S), 13g of calcium sulfide (CaS), heated in a water bath at 85°C, added dropwise a sodium carbonate solution (10wt%) to control the pH to 10, and vigorously stirred (2000rpm) for 2h to generate a sol. The sol was filtered, washed 3 times with absolute ethanol, put into a 90° C. 4 SCN) were mixed evenly, then put into a vacuum furnace, evacuated, heated to 850°C at a rate of 10°C / min, kept for 2h, cooled naturally, and pulverized to obtain Na and Ca-doped cerium sulfide. Take 75g of the above-mentioned cerium sulfide and dissolve it in 500ml of absolute ethanol, add 41ml of ammonia water (32%), then add 3.5g of ammonium fluoride and 2g of PVP, and stir at room temperature for 2h; dissolve 7.5g of zinc oxide in 500ml of absolute ethanol, add to the above solution, and...

Embodiment 3

[0041] Weigh 50g of mica powder (10-50 microns) at room temperature and dissolve in 1000ml of deionized water, stir evenly to make a bottom solution; add 246g of cerium chloride (CeCl 3 ), 18g sodium sulfide (Na 2 S), heated in a water bath at 90°C, added dropwise sodium carbonate solution (10wt%) to control the pH value to 10, and vigorously stirred (2000rpm) for 2h to generate a sol. The sol was filtered, washed 3 times with absolute ethanol, put into a 100°C oven for drying, took out after cooling and mixed with 85g ammonium thiocyanate (NH 4 SCN) were mixed evenly, then put into a vacuum furnace, evacuated, heated up to 900°C at a rate of 10°C / min, kept for 2h, cooled naturally, and pulverized to obtain Na-doped cerium sulfide. Take 75g of the above-mentioned cerium sulfide and dissolve it in 500ml of absolute ethanol, add 42ml of ammonia water (32%), then add 3.5g of ammonium fluoride and 2g of PVP, and stir at room temperature for 2h; dissolve 7.5g of zinc oxide in 500m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com