Magnesium aluminum spinel wrapping type gamma-Ce2S3 red pigment and preparation method thereof

A magnesia-alumina spinel and wrapped technology, which is applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, chemical instruments and methods, magnesium aluminate, etc., can solve the problems affecting the stability and reliability of production and preparation and product stability In order to achieve the effect of stable and reliable product performance, high temperature stability and corrosion resistance, and expand the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

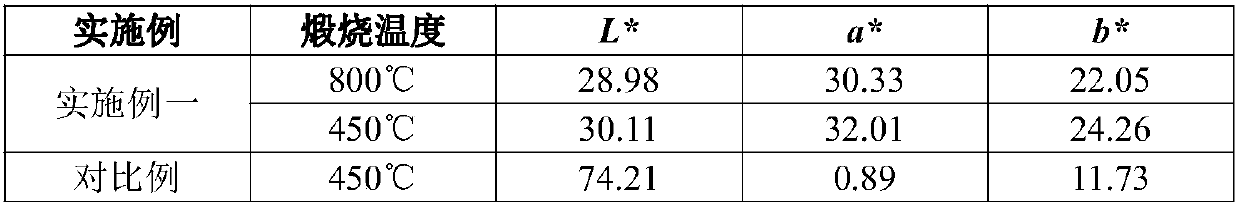

Embodiment 1

[0029] In this embodiment, a magnesium-aluminum spinel-wrapped type γ-Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0030] (1) Preparation of encapsulated CeO by liquid phase method 2 Precursor Precipitation

[0031] (1-1) 4g Ce(NO 3 ) 3 ·6H2 O, 4gAl(NO 3 ) 3 9H 2 O and, 3g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 5 mL of water, then dropped into solvent A consisting of 12 mL of triton, 36 mL of cyclohexane and 8 mL of n-hexanol, and stirred at room temperature for 5.5 h to obtain microemulsion A;

[0032] (1-2) Add 4 mL of concentrated ammonia water dropwise into a solvent B consisting of 12 mL of triton, 36 mL of cyclohexane and 8 mL of n-hexanol, and stir at room temperature for 5.5 h to prepare microemulsion B;

[0033] (1-3) According to the volume ratio of solvent A:solvent B=1:1, after mixing microemulsion A and microemulsion B, continue stirring at room temperature for 5.5h, add isopropanol to break the emulsion, and obtain aluminum h...

Embodiment 2

[0039] In this embodiment, a magnesium-aluminum spinel-wrapped type γ-Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0040] (1) Preparation of encapsulated CeO by liquid phase method 2 Precursor Precipitation

[0041] (1-1) 5g CeCl 3 ·7H 2 O, 5gAlCl 3 ·6H 2 O, 3g MgCl 2 ·6H 2 O was dissolved in 6 mL of water, then dropped into a solvent A consisting of 10 mL of triton, 30 mL of cyclohexane and 8 mL of n-hexanol, and stirred at room temperature for 4 hours to obtain microemulsion A;

[0042] (1-2) Combine 5mLNaOH and Na 2 CO 3 The mixed solution (according to the molar ratio NaOH:Na 2 CO 3 = 2: 1) was dropped into a solvent B composed of 10mL triton, 30mL cyclohexane and 8mL n-hexanol, and stirred at room temperature for 4h to obtain microemulsion B;

[0043] (1-3) Solvent A:solvent B=1:1 according to the volume ratio, after mixing microemulsion A and microemulsion B, continue to stir at room temperature for 5h, add acetone to demulsify, ...

Embodiment 3

[0049] In this embodiment, a magnesium-aluminum spinel-wrapped type γ-Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0050] (1) Preparation of encapsulated CeO by liquid phase method 2 Precursor Precipitation

[0051] (1-1) 5g CeCl 3 ·7H 2 O, 4gAl(NO 3 ) 3 9H 2 O, 3g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 6 mL of water, then dropped into solvent A consisting of 9.5 mL of triton, 32 mL of cyclohexane and 8 mL of n-hexanol, and stirred at room temperature for 6 h to obtain microemulsion A;

[0052] (1-2) 5 mL of NaOH solution with a concentration of 1.5 mol / L was dropped into a solvent B composed of 9.5 mL of triton, 32 mL of cyclohexane and 8 mL of n-hexanol, and stirred at room temperature for 6 hours to obtain microemulsion B;

[0053] (1-3) According to the volume ratio of solvent A:solvent B=1:1, after mixing microemulsion A and microemulsion B, continue stirring at room temperature for 6h, add acetone to break the emulsion, and obtain al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com