Method for preparing gamma-Ce2S3 red pigment by taking ion-doped CeO2 as precursor and vulcanizing

A technology of ion doping and precursor, which is applied in the field of preparation of ion-doped γ-Ce2S3 red colorant, can solve the problems of unstable crystal structure, insufficient thickness of cladding layer, loss of red color of crystal, etc., and achieve high temperature stability Improvement, high industrial use value, strong high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

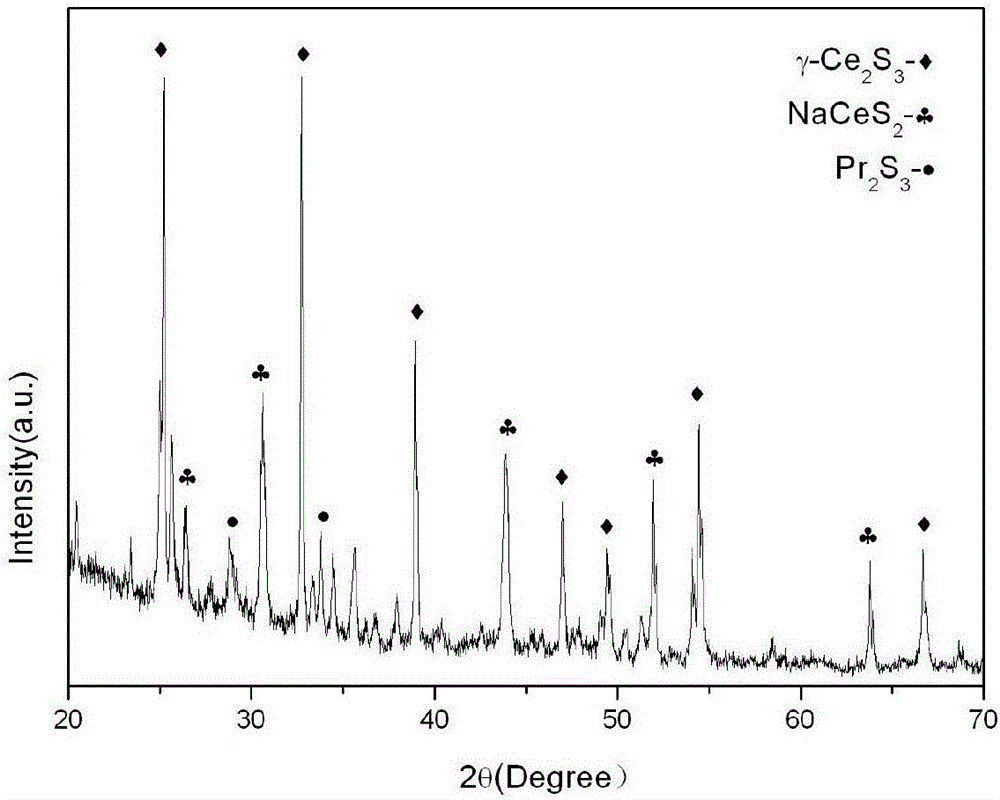

[0026] In this embodiment, a kind of ion-doped CeO 2 Preparation of γ~Ce for precursor vulcanization 2 S 3 The method for red pigment, its step is as follows:

[0027] (1) Preparation of ion-doped CeO by liquid phase method 2 precursor suspension

[0028] 2g Ce(NO3 ) 3 ·6H 2 O, 0.1g Pr(NO 3 ) 3 ·6H 2 O dissolved in 70mL C 2 h 8 N 2 , stirred vigorously for 100 min, then transferred to a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 250 ° C for 12 h to obtain Pr 3+ ion-doped CeO 2 Precursor suspension;

[0029] (2) Preparation of Pr 3+ ion-doped CeO 2 Precursor powder

[0030] Put the above Pr 3+ ion-doped CeO 2 The precursor suspension was centrifuged at 6000r / min for 3min, washed with water, washed with alcohol, and dried to obtain Pr 3+ ion-doped CeO 2 Precursor powder;

[0031] (3) Preparation of γ~Ce by vulcanization heat treatment 2 S 3 red pigment

[0032] Place 5g NaSCN in the lower layer of the double-layer crucible,...

Embodiment 2

[0034] In this embodiment, a kind of ion-doped CeO 2 Preparation of γ~Ce for precursor vulcanization 2 S 3 The method for red pigment, its step is as follows:

[0035] (1) Preparation of ion-doped CeO by liquid phase method 2 precursor suspension

[0036] 2g CeCl 3 ·7H 2 O, 0.2g Eu(NO 3 ) 3 ·6H 2 O was dissolved in 80mL water, stirred vigorously for 80min, then transferred to a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 240°C for 11h to obtain Eu 3+ ion-doped CeO 2 Precursor suspension;

[0037] (2) Preparation of Eu 3+ ion-doped CeO 2 Precursor powder

[0038] The above Eu 3+ ion-doped CeO 2 The precursor suspension was centrifuged at 6000r / min for 5min, washed with water, washed with alcohol, and dried to obtain Eu 3+ ion-doped CeO 2 Precursor powder;

[0039] (3) Preparation of γ~Ce by vulcanization heat treatment 2 S 3 red pigment

[0040] Place 5g NaHS in the lower layer of the double-layer crucible, and place 0.4g of t...

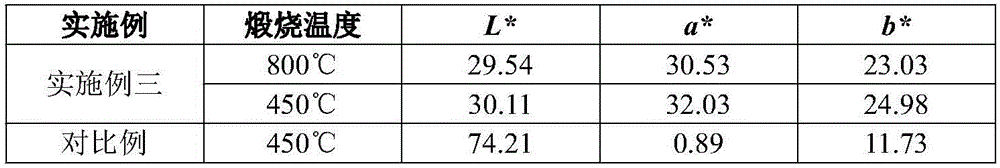

Embodiment 3

[0042] In this embodiment, a kind of ion-doped CeO 2 Preparation of γ~Ce for precursor vulcanization 2 S 3 The method for red pigment, its step is as follows:

[0043] (1) Preparation of ion-doped CeO by liquid phase method 2 precursor suspension

[0044] 2.5g CeCl 3 ·7H 2 O, 0.15g Pr(NO 3 ) 3 ·6H 2 O dissolved in 70mL C 2 h 8 N 2 , stirred vigorously for 80 min, then transferred to a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 220 ° C for 10 h to obtain Pr 3+ ion-doped CeO 2 Precursor suspension;

[0045] (2) Preparation of Pr 3+ ion-doped CeO 2 Precursor powder

[0046] Put the above Pr 3+ ion-doped CeO 2 The precursor suspension was centrifuged at 6000r / min for 5min, washed with water, washed with alcohol, and dried to obtain Pr 3+ ion-doped CeO 2 Precursor powder;

[0047] (3) Preparation of γ~Ce by vulcanization heat treatment 2 S 3 red pigment

[0048] Place 4.5g NaSCN in the lower layer of the double-layer crucible,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com