Colorant and preparation method thereof

A coloring agent and compound technology, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problem of brightness without phosphorus-containing rare earth sulfide colorants and without phosphorus-containing rare earth sulfide colorants and other problems, to achieve the effect of omitting the sewage treatment link, improving the vividness and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056]

[0057] The preparation method of the coloring agent of the present invention comprises the following steps: mixing a rare earth compound, a sulfur source, a phosphorus compound and an alkali metal compound to obtain a mixture, and reacting the mixture at 700-1500° C. to obtain the coloring agent. The above-mentioned preparation method does not include the fluorine washing treatment process, so the production cost can be saved, the industrial waste liquid can be reduced, and the process flow can be shortened. The order of mixing is not particularly limited. For example, the rare earth compound, the sulfur source and the phosphorus-containing compound are uniformly mixed, and then an alkali metal compound is added as a flux, and the mixture is obtained by uniform mixing. In another example, the rare earth compound, the sulfur source, the phosphorus-containing compound and the alkali metal compound are uniformly mixed together to obtain a mixture.

[0058] In the prep...

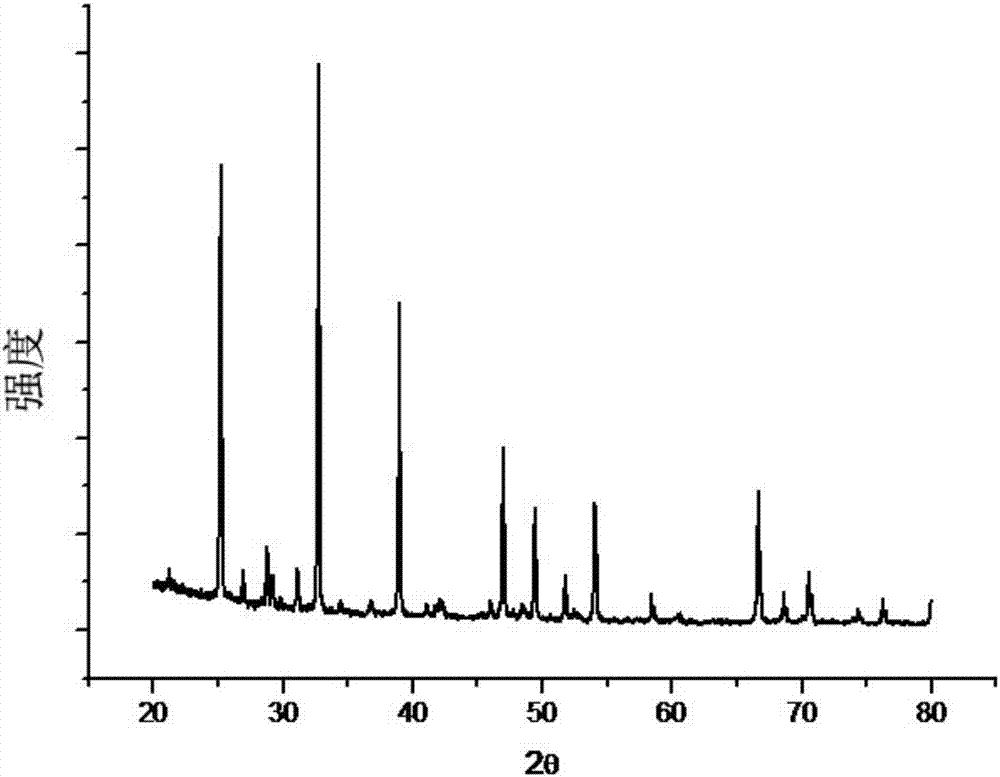

Embodiment 1

[0073] Mix 0.75 mol of sublimated sulfur, 0.15 mol of cerium carbonate, 0.0095 mol of anhydrous sodium carbonate and 0.063 mol of ammonium phosphate, and react at 1000°C for 3 hours. The reaction product is ground, washed, and dried to obtain the colorant Ce 0.3 S 0.45 0.063[CePO 4 ]. The chromaticity coordinates are (L*=55, a*=58, b*=40).

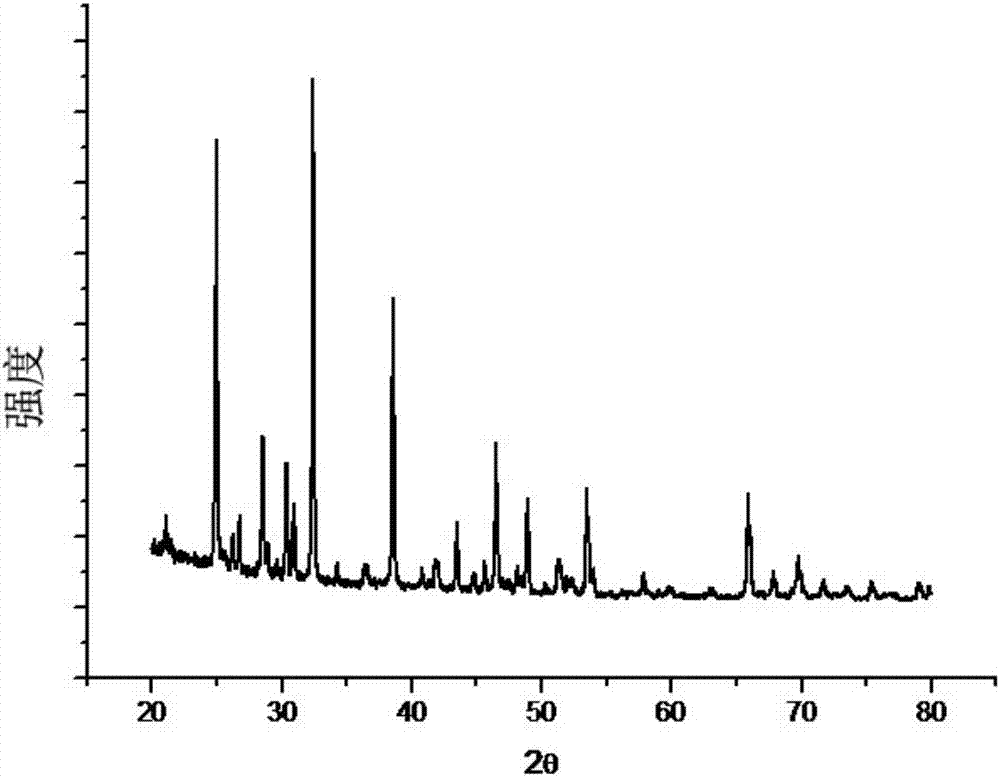

Embodiment 2

[0075] Mix 0.5 mol of sublimated sulfur, 0.15 mol of cerium oxide, 0.01125 mol of anhydrous sodium carbonate and 0.0675 mol of ammonium dihydrogen phosphate, and react at 1000°C for 3 hours. The reaction product is ground, washed, and dried to obtain the colorant Ce 0.3 S 0.45 0.0675[CePO 4 ]. The chromaticity coordinates are (L*=55, a*=58, b*=40).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com