White glue for paint ink digital printing and preparation process of white glue

A technology of digital printing and white glue, applied in the field of textile printing, can solve the problems of insufficient wetting and leveling of color inks, insufficient color depth, and easy blockage of printing nozzles, etc., to achieve bright colors, improve color depth, Effects that are easy to control and manipulate

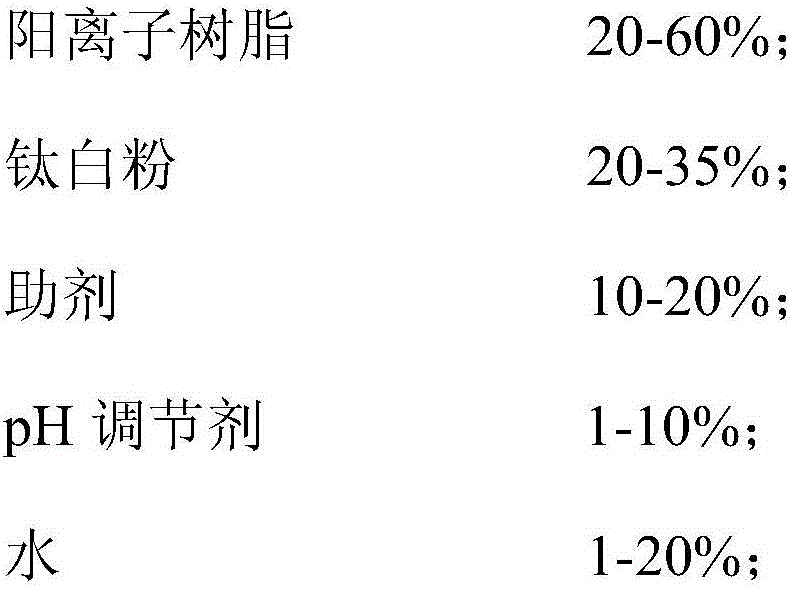

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation process of white glue for paint ink digital printing, comprising the following steps:

[0046] 1) the auxiliary agent of formula quantity is divided into two parts, is recorded as the first auxiliary agent and the second auxiliary agent respectively; Said first auxiliary agent comprises wetting agent, dispersant, defoamer and anti-blocking board agent; Said The second auxiliary agent is a thickener;

[0047] 2) Put the resin in the formulated amount, the water in the formulated amount and the first auxiliary agent into the dispersion kettle, and disperse for 8-12 minutes to obtain the first mixture;

[0048] 3) Put the second auxiliary agent into the dispersion tank and mix with the first mixture, and disperse for 10-20min to obtain the second mixture;

[0049] 4) Put the titanium dioxide of formula quantity into the dispersing tank and mix with the second mixture, disperse for 15-20min, and obtain the third mixture;

[0050] 5) After dispersing and grin...

Embodiment 1

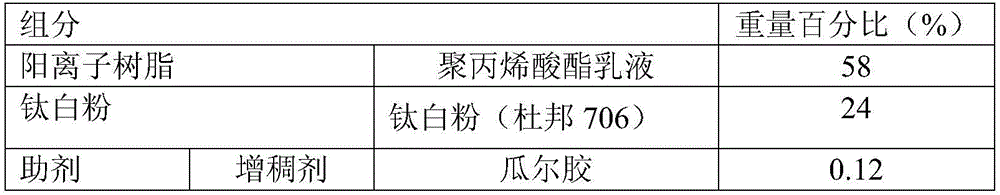

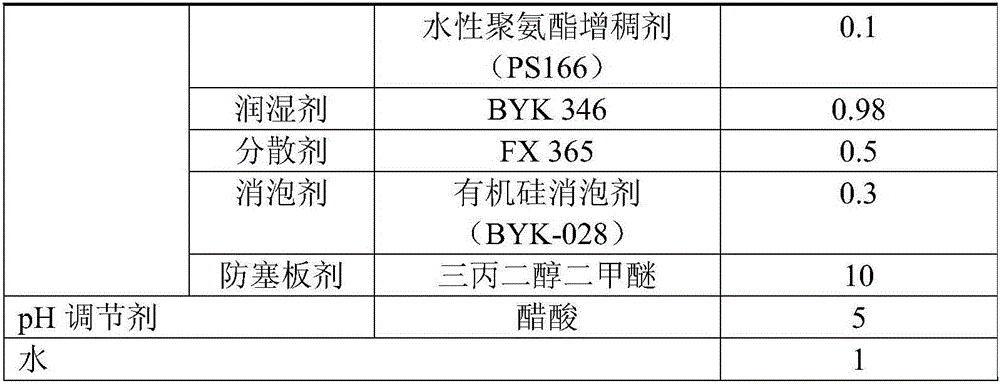

[0053] A kind of white glue comprises the following components by weight percentage (see Table 1):

[0054] Table 1 The composition list of embodiment 1 white mortar

[0055]

[0056]

[0057]According to the formula in Table 1, prepare the white glue according to the following steps:

[0058] 1) Accurately weigh each component in Table 1 respectively;

[0059] 2) Add cationic resin, water, wetting agent, dispersant, defoamer and anti-blocking agent to the dispersion kettle in sequence, and disperse at a speed of 400-600r / min for 10min to obtain the first mixture;

[0060] 3) Put the thickener into the dispersing tank and mix with the first mixture, and disperse for 10 minutes at a speed of 600-800r / min to obtain the second mixture;

[0061] 4) Put the titanium dioxide into the dispersion tank and mix with the second mixture, and disperse for 20 minutes at a speed of 1500-1800r / min to obtain the third mixture;

[0062] 5) Grinding the third mixture once for 30 minutes...

Embodiment 2

[0066] A kind of white glue comprises the following components by weight percentage (see Table 2):

[0067] Table 2 The component list of embodiment 2 white mortar

[0068]

[0069]

[0070] According to the formula in Table 2, prepare the white glue according to the following steps:

[0071] 1) Accurately weigh each component in Table 2 respectively;

[0072] 2) Add cationic resin, water, wetting agent, dispersant, defoamer and anti-blocking agent to the dispersion kettle in sequence, and disperse at a speed of 400-600R / min for 8 minutes to obtain the first mixture;

[0073] 3) Put the thickener into the dispersing tank and mix with the first mixture, and disperse for 15 minutes at a speed of 800-1000R / min to obtain the second mixture;

[0074] 4) Put the titanium dioxide into the dispersion tank and mix with the second mixture, and disperse for 15 minutes at a speed of 1500-1800R / min to obtain the third mixture;

[0075] 5) Grinding the third mixture once for 25 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com