Super-weather-resistant composite waterproof roll and preparation method thereof

A waterproofing membrane, super weather-resistant technology, applied in chemical instruments and methods, synthetic resin layered products, roofing using flexible materials, etc. Application fields and development issues, to achieve the effect of good static load resistance, high elongation at break and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

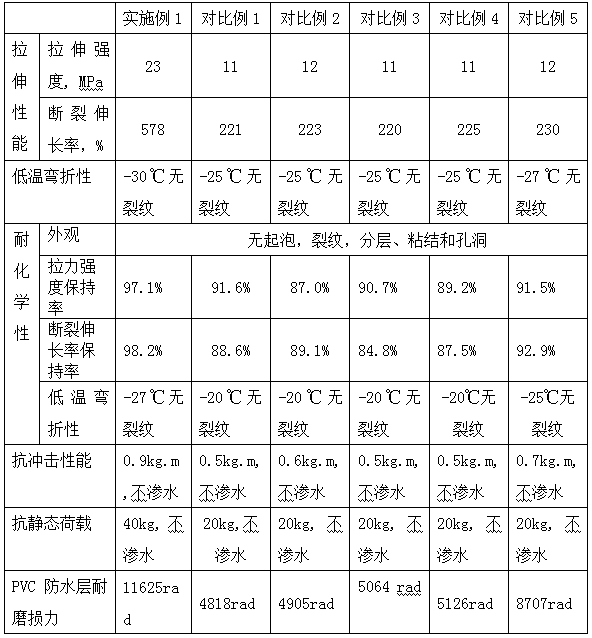

[0035] Embodiment 1 A kind of super weather-resistant composite waterproof membrane

[0036] A super-weather-resistant composite waterproof membrane of the present invention comprises the following raw materials: PVC resin, diisodecyl phthalate, dibutyl ester, anti-ultraviolet agent, propylene oxide glycerol polyether, tackifier, lithium-based bentonite , aluminate, castor oil alkyd resin, zinc stearate;

[0037] A super-weather-resistant composite waterproof membrane of the present invention comprises the following raw materials in parts by weight: 60 parts of PVC resin, 25 parts of diisodecyl phthalate, 10 parts of dibutyl fat, 5 parts of anti-ultraviolet agent, epoxy resin 12 parts of propane glycerol polyether, 10 parts of tackifier, 15 parts of lithium bentonite, 3.0 parts of aluminate, 12 parts of castor oil alkyd resin, 8 parts of zinc stearate;

[0038] The diisodecyl phthalate has an acid value of ≤0.1 mgKOH / g, a viscosity of 115-136mPa.s at 20°C, and a water content...

Embodiment 2

[0047] Embodiment 2 A kind of preparation method of super weather-resistant composite waterproof coiled material

[0048] A super-weather-resistant composite waterproof coiled material of the present invention includes a geotextile layer, a PVC waterproof layer, a reinforcing rib layer, a PVC waterproof layer and a geotextile layer from top to bottom, and the reinforcing rib layer adopts glass fiber; the super-weather-resistant composite waterproof membrane of the present invention The preparation steps of the coil are as follows:

[0049] (a) Put PVC resin, diisodecyl phthalate, dibutyl fat, anti-ultraviolet agent, propylene oxide glycerol polyether, tackifier, castor oil alkyd resin, zinc stearate in Mix in a high-speed homogenizer for 20 minutes, stir and mix evenly to make a mixture, and slowly heat to 72°C;

[0050] (b) After it starts to melt, add lithium-based bentonite, transfer to the rubber mixer for masticating and then knead, the masticating temperature is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com