Mercury re-releasing inhibitor in wet flue gas desulfurization slurry and application method thereof

A technology for wet flue gas desulfurization and desulfurization slurry, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reducing mercury removal efficiency of wet desulfurization system, secondary pollution, etc., and achieves the solution of mercury pollution. problems, inhibiting re-release, and improving the efficiency of mercury removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

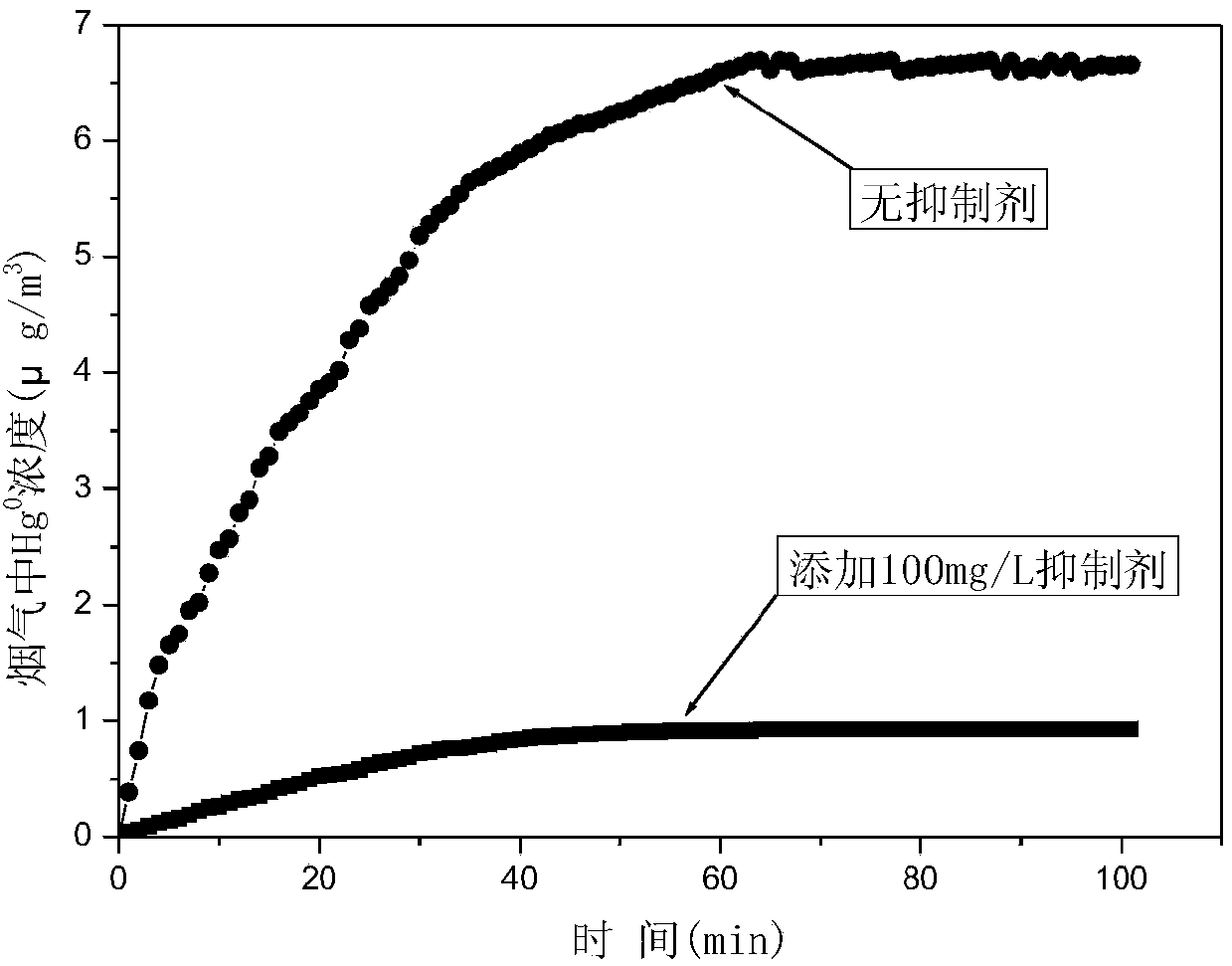

[0031] The desulfurization slurry used in this example is a limestone slurry with a mass fraction of limestone of 1%. Mercury re-release inhibitors during the wet flue gas desulfurization process are added to the limestone slurry. The dosage is 100 mg / L. The inhibitor composition is: sulfur Sodium sulfide 45wt%, sodium sulfide 55wt%, adjust the pH value of limestone slurry to 5.5, the temperature is 55 ℃, the simulated mixed flue gas composition is 12% CO 2 , with a volume fraction of 6% O 2 , SO with a gas concentration of 300ppm 2 , the rest is N 2 , using a peristaltic pump to pump Hg with a concentration of 50 μg / L into the bubbler reactor at a flow rate of 10 mL / h 2+ solution, the absorption liquid volume in the bubble reactor is 400mL, and the flue gas flow rate at the inlet is 1L / min. Hg in outlet flue gas 0 Concentration changes with time as figure 1 shown. The figure shows that the Hg in the outlet flue gas before adding the inhibitor 0 After the concentration ...

Embodiment 2

[0033] The desulfurization slurry used in this example is a limestone slurry with a limestone mass fraction of 1%. The mercury re-release inhibitor in the wet flue gas desulfurization process is added to the limestone slurry. The dosage is 200 mg / L. The inhibitor composition is: sulfur Potassium sulfide 35wt%, sodium sulfide 65wt%, adjust the pH value of the limestone slurry to 5.5, the temperature is 55°C, and the simulated mixed flue gas composition is 12% CO 2 , with a volume fraction of 6% O 2 , SO with a gas concentration of 300ppm 2 , the rest is N 2 , using a peristaltic pump to pump Hg with a concentration of 50 μg / L into the bubbling reactor at a flow rate of 10 mL / h 2+ solution, the absorption liquid volume in the bubble reactor is 400mL, and the flue gas flow rate at the inlet is 1L / min. The inhibition rate of the inhibitor on mercury re-release in limestone slurry reaches 90.4%.

Embodiment 3

[0035]The desulfurization slurry used in this example is a limestone slurry with a limestone mass fraction of 1%. The mercury re-release inhibitor in the wet flue gas desulfurization process is added to the limestone slurry. The dosage is 300 mg / L. The inhibitor composition is: sulfur Sodium sulfide 33wt%, sodium sulfide 67wt%, adjusted limestone H value 5.5, temperature 55°C, simulated mixed flue gas composition is 12% CO 2 , with a volume fraction of 6% O 2 , SO with a volume concentration of 300ppm 2 , the rest is N 2 , using a peristaltic pump to pump Hg with a concentration of 50 μg / L into the bubbling reactor at a flow rate of 10 mL / h 2+ solution, the absorption liquid volume in the bubble reactor is 400mL, and the flue gas flow rate at the inlet is 1L / min. The inhibition rate of the inhibitor on mercury re-release in limestone slurry reaches 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com