Method for synergically removing sulfate and Cr (VI) in wastewater through sponge iron and microorganisms

A sponge iron, sulfate technology, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problems of loose structure, low activity, and low unit microbial content, and achieves enhanced reduction process, The effect of maintaining reducing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

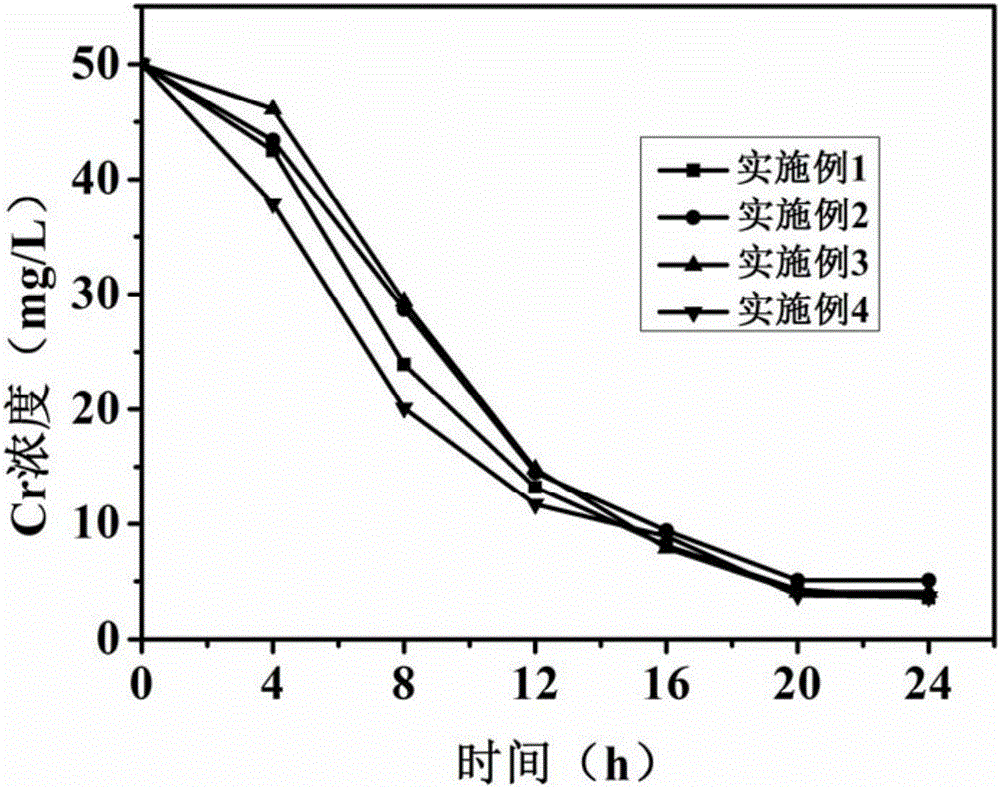

Embodiment 1

[0038] A method for removing sulfate and Cr(Ⅵ) wastewater in cooperation with sponge iron and microorganisms, comprising the following steps:

[0039] (1) Preparation of sponge iron

[0040] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 1:1, reaction temperature 1160°C, and reaction time 20 min, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.2 g / L, which is designated as reaction solution A.

[0041] (2) Preparation of sulfate reducing bacteria SRB

[0042] Select 2 rings from a sulfate-reducing bacterium—Desulfovibrio (Desulfovibrio; Desulfovibrio desulfurization subspecies) purchased from China General Microorganism Culture Collection Management Center (Chaoyang District, Beijing, China, Zip Code 100101, No. 1.3469), Transfer it to 30ml of Desulfovibrio nutrient medium, culture at 35°C in...

Embodiment 2

[0054] A method for removing sulfate and Cr(Ⅵ) wastewater in cooperation with sponge iron and microorganisms, comprising the following steps:

[0055] (1) Preparation of sponge iron

[0056]Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 1:1, reaction temperature 1160°C, and reaction time 20 min, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.1 g / L, which is designated as reaction solution A.

[0057] (2) Preparation of sulfate reducing bacteria SRB

[0058] Select 2 rings from a kind of sulfate-reducing bacterium—Desulfovibrio (same as Example 1) purchased by China Common Microorganism Culture Collection and Management Center, transfer it to 30ml nutrient solution, and cultivate it in the dark at 35°C for 3d, to 5% of the inoculum was expanded with the proliferation medium for 2 days, centri...

Embodiment 3

[0070] A method for removing sulfate and Cr(Ⅵ) wastewater in cooperation with sponge iron and microorganisms, comprising the following steps:

[0071] (1) Preparation of sponge iron

[0072] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 1:1, reaction temperature 1160°C, and reaction time 20 min, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.5 g / L, which is designated as reaction solution A.

[0073] (2) Preparation of sulfate reducing bacteria SRB

[0074] Select 2 rings from a kind of sulfate-reducing bacterium—Desulfovibrio (same as Example 1) purchased by China Common Microorganism Culture Collection and Management Center, transfer it to 30ml nutrient solution, and cultivate it in the dark at 35°C for 3d, to 5% of the inoculum was expanded with proliferation medium for 2 days, and centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com