Method for removing sulfate and Cd (II) wastewater through sponge iron and microorganism synergism

A sponge iron, sulfate technology, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problems of low unit microbial content, poor sedimentation performance, low activity, etc. Good removal performance, strong electrochemical enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

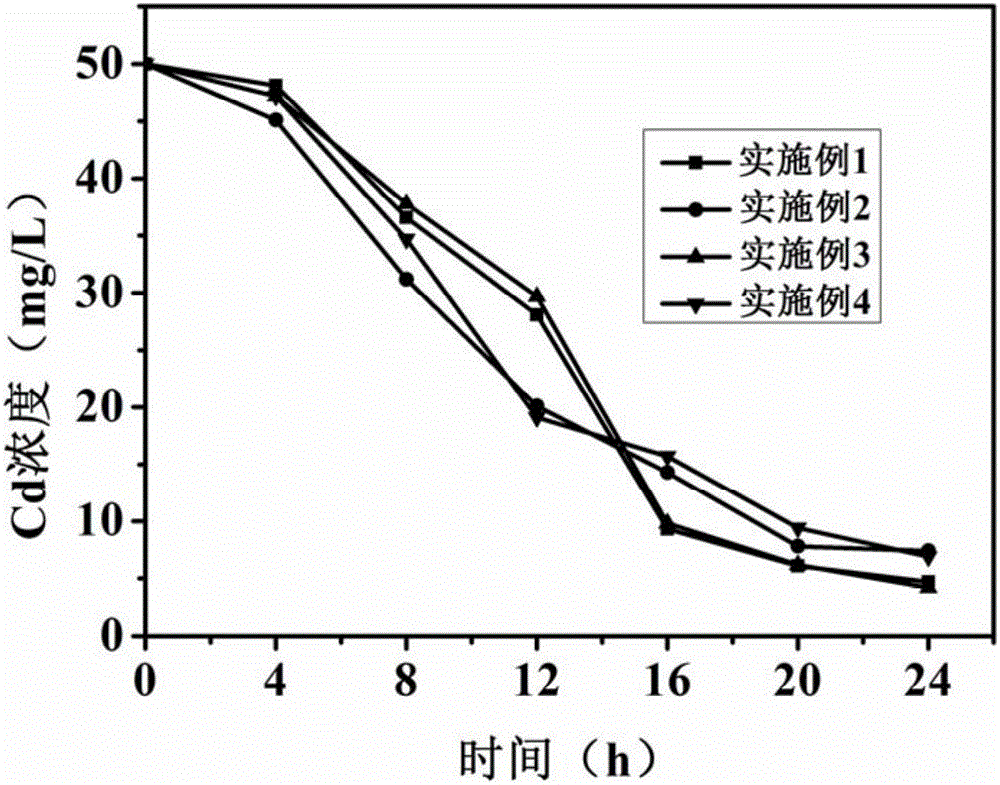

Examples

Embodiment 1

[0040] A method for removing sulfate and Cd(II) wastewater in cooperation with sponge iron and microorganisms, comprising the following steps:

[0041] (1) Preparation of sponge iron

[0042] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 1:2, reaction temperature 1200°C, and reaction time 25 minutes, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.6 g / L, which is designated as reaction solution A.

[0043] (2) Preparation of sulfate reducing bacteria SRB

[0044] A kind of sulfate-reducing bacterium—Desulfovibrio (Desulfovibrio; Desulfovibrio desulfurization subspecies) purchased from China General Microorganism Culture Collection Management Center (Chaoyang District, Beijing, China, zip code 100101, number 1.3469) was selected for 2 rings, and the It was transferred to 40ml of Desulfovibrio...

Embodiment 2

[0056] A method for removing sulfate and Cd(II) wastewater in cooperation with sponge iron and microorganisms, comprising the following steps:

[0057] (1) Preparation of sponge iron

[0058] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 1:2, reaction temperature 1200°C, and reaction time 25 minutes, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.4 g / L, which is designated as reaction solution A.

[0059] (2) Preparation of sulfate reducing bacteria SRB

[0060] A kind of sulfate-reducing bacterium---Desulfovibrio (Desulfovibrio) purchased from China Common Microorganism Culture Collection Management Center (Chaoyang District, Beijing, China, Zip Code 100101, No. 1.3469) picks 2 rings, transfers it in 40ml nutrient solution, Cultivate in the dark at 35°C for 5 days, use the proliferation medi...

Embodiment 3

[0072] A method for removing sulfate and Cd(II) wastewater in cooperation with sponge iron and microorganisms, comprising the following steps:

[0073] (1) Preparation of sponge iron

[0074] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 1:2, reaction temperature 1200°C, and reaction time 25 minutes, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.3 g / L, which is designated as reaction solution A.

[0075] (2) Preparation of sulfate reducing bacteria SRB

[0076] A sulfate-reducing bacterium—Desulfovibrio bacilli purchased from the China General Microorganism Culture Collection Management Center (Chaoyang District, Beijing, China, Zip Code 100101, No. 1.3469) was selected for 2 rings, transferred to 30ml of nutrient solution, and incubated at 35°C Cultivate in the dark for 3 days, use prolif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com