Synchronous lifting table driven by gas springs

A technology of synchronous lifting and gas springs, which is applied to the legs of general furniture, desks with variable table heights, tables, etc., can solve the problems of difficult synchronization of lifting legs, high manufacturing cost, and complex structure, and achieve recovery and energy storage efficiency The effect of high, long service life and few moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

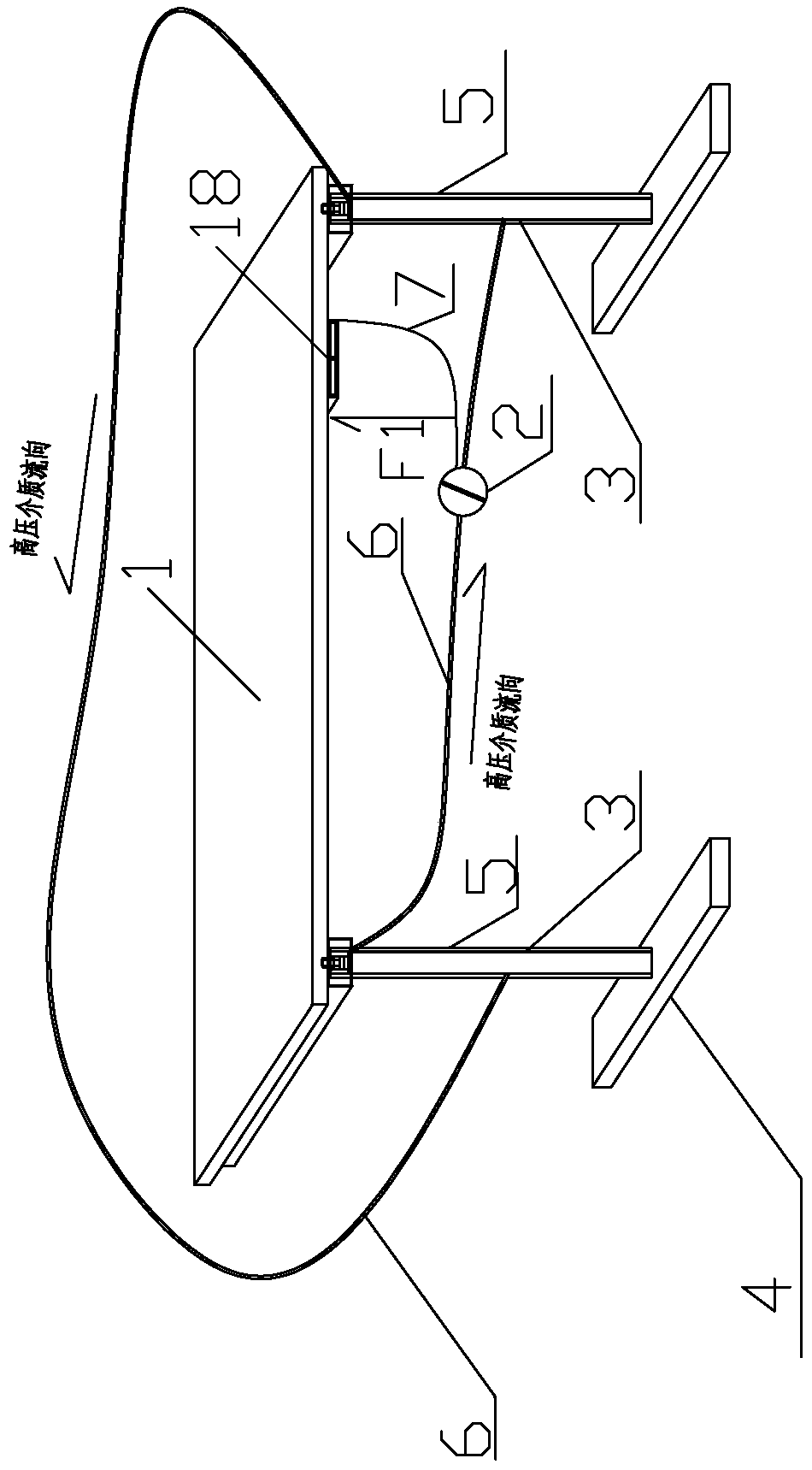

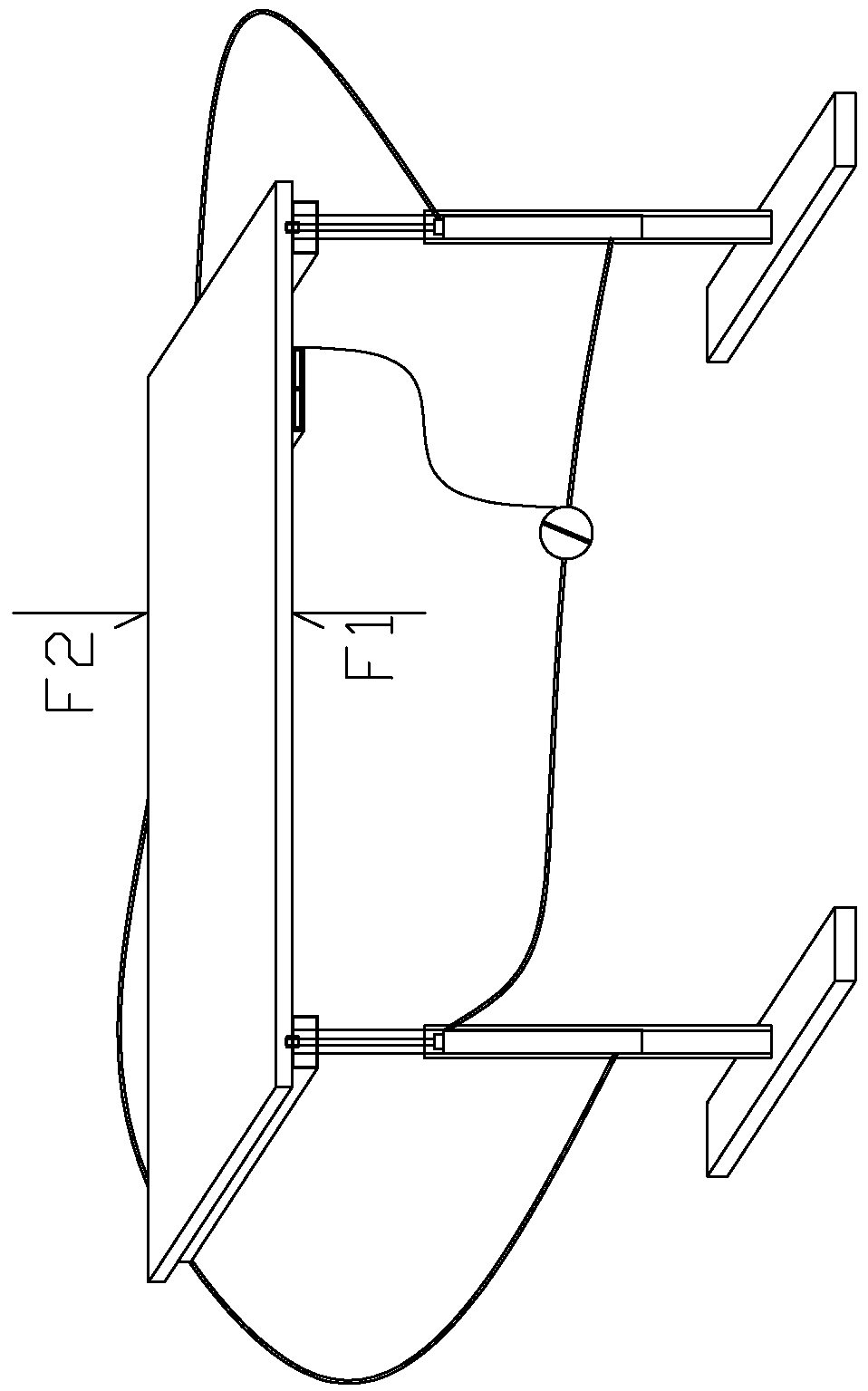

[0029] like figure 1 , 2 shown.

[0030] A gas spring-driven synchronous lifting table, which includes a desktop 1, the desktop 1 is installed on the base 4 through two gas springs 3, and each gas spring 3 is installed in a telescopic sleeve 5 to increase the desktop The stability of the telescopic sleeve 5 is fixed on the lower part of the desktop, and the other part is fixed on the base 4, and the synchronous lifting and lowering of the desktop 1 is realized through the synchronous expansion and contraction of the gas spring 3; the rod chamber of the first gas spring ( Rodless chamber) and the rodless chamber (rod chamber) of the second gas spring are connected through the connecting pipe 6 (a high-pressure resistant hose or a hard pipe with an expansion joint that matches the internal pressure of the gas spring) is connected , the rod chamber (rodless chamber) of the second gas spring and the rodless chamber (rod chamber) of the first gas spring 3 are also connected throu...

Embodiment 2

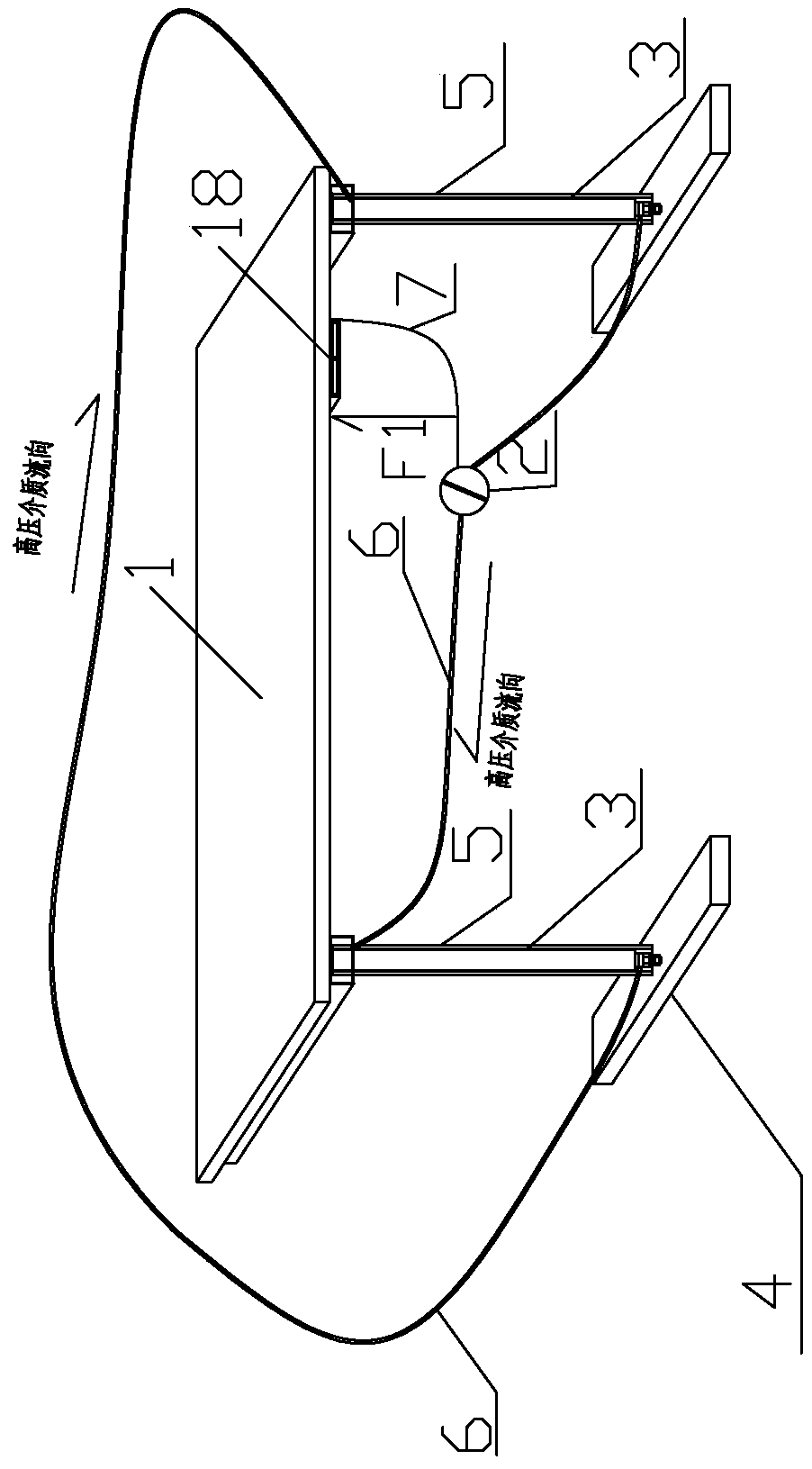

[0036] like image 3 , 4 shown.

[0037] The difference between this embodiment and the first embodiment is that the gas springs 3 are installed between the desktop and the base in a reversed form, and the rest are the same as the first embodiment.

Embodiment 3

[0039] like Figure 5-6 shown.

[0040] The difference between this embodiment and Embodiment 1 is that the gas springs 3 are installed one positive and one reverse (one gas spring has a rod cavity connected to the other gas spring without a lever cavity), and the piston rod of the gas spring 3 in one lifting leg 2 is connected to the The base 4 is fixedly connected, and the non-rod end of the gas spring 3 in the other lifting leg 2 is fixedly connected with the base 4. The rod chamber of the gas spring installed in the forward direction and the rodless chamber of the gas spring installed in the reverse direction are connected through the flexible connecting pipe 6, and at the same time The rodless chamber of the gas spring installed in the forward direction and the rod chamber of the gas spring installed in the reverse direction are connected through the flexible connecting pipe 6, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com