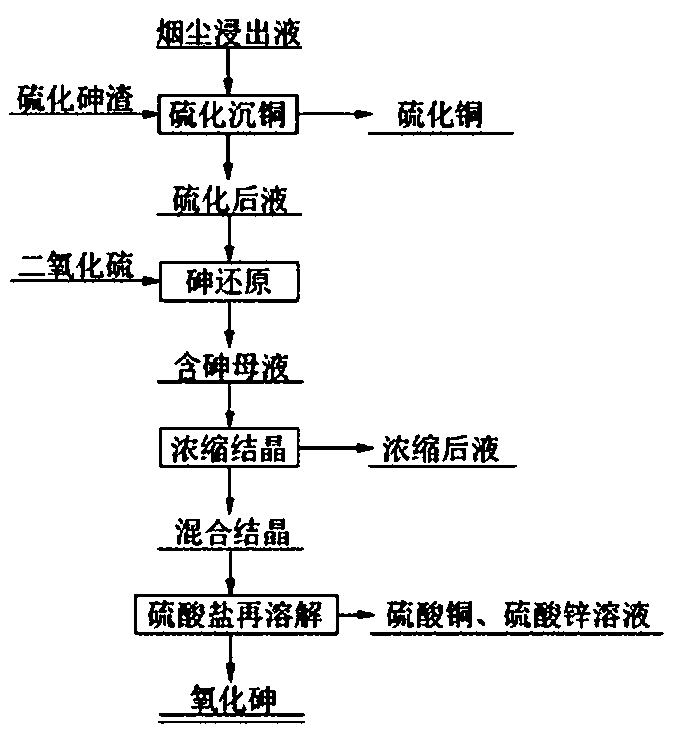

Comprehensive recovery method for arsenic in arsenic sulfide residues and smoke leaching liquid in copper smelting

A recovery method and technology for arsenic sulfide, applied in chemical instruments and methods, arsenic oxide/arsenic hydroxide/oxyacid arsenic, arsenic compounds, etc. Complex problems, to achieve the effect of high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Copper sulfide

[0047] At a temperature of 60°C, a time of 5 hours, a stirring speed of 83r / min, and a liquid-to-solid ratio of 5:1 (L:kg) between the soot leaching solution and arsenic sulfide slag, the arsenic sulfide slag and soot leaching solution were subjected to atmospheric pressure sulfidation copper precipitation treatment, and filtered to obtain Copper sulfide and post-sulfide solution. The composition of copper sulfide and post-sulfurization solution is shown in the following table:

[0048] name

Cu

As

Zn

h 2 SO 4

Liquid after vulcanization (g / L)

13.23

40.53

46.92

73.63

Copper sulfide (wt%)

45.58

7.97

2.96

-

[0049] 2. Arsenic reduction

[0050] At a temperature of 65°C and a time of 3 hours, under the above conditions, introduce sulfur dioxide into the vulcanized solution obtained in step 1, the amount of sulfur dioxide introduced is 0.86 times of the arsenic content in the vulcaniz...

Embodiment 2

[0058] 1. Copper sulfide

[0059] The composition of copper sulfide and post-sulfurization solution is shown in the following table:

[0060] name

Cu

As

Zn

h 2 SO 4

Liquid after vulcanization (g / L)

12.23

45.35

48.25

80.24

Copper sulfide (wt%)

48.35

6.78

2.87

-

[0061] 2. Arsenic reduction

[0062] 3. Concentrated crystallization

[0063] At a temperature of 80°C, a time of 6 hours, and a vacuum of -0.02 MPa, under the above conditions, the arsenic-containing mother liquor obtained in step 2 is concentrated and crystallized, and filtered to obtain mixed sulfate crystals and concentrated liquid. The composition of the concentrated liquid is shown in the following table:

[0064] name

Cu

As

Zn

h 2 SO 4

Concentrated liquid (g / L)

38

4.56

3.27

596

[0065] 4. Sulfate redissolution

[0066] At a temperature of 40°C, a time of 3 hours, and a stirring speed...

Embodiment 3

[0069] 1. Copper sulfide

[0070] At a temperature of 60°C, a time of 5 hours, a stirring speed of 83r / min, and a liquid-to-solid ratio of 6:1 (L:kg) between the soot leaching solution and arsenic sulfide slag, the arsenic sulfide slag and soot leaching solution were subjected to atmospheric pressure sulfide copper precipitation treatment, and filtered to obtain Copper sulfide and post-sulfide solution. The composition of copper sulfide and post-sulfurization solution is shown in the following table:

[0071] name

Cu

As

Zn

h 2 SO 4

Liquid after vulcanization (g / L)

11.73

38.96

40.76

63.63

Copper sulfide (wt%)

44.27

8.23

3.27

-

[0072] 2. Arsenic reduction

[0073] At a temperature of 65°C and a time of 3 hours, under the above conditions, introduce sulfur dioxide into the vulcanized solution obtained in step 1, the amount of sulfur dioxide introduced is 1 times the content of arsenic in the vulcanized so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com